In the vast and complex world of modern healthcare, generic drugs are the unsung heroes. They are the workhorses of the pharmacy, the bedrock of treatment affordability, and a critical engine of economic sustainability for healthcare systems worldwide. In the United States alone, generics account for over 90% of all prescriptions filled, yet they represent a mere 18% of total prescription drug spending.1 This incredible value proposition, which saved the U.S. healthcare system a staggering $408 billion in 2022, is not a happy accident. It is the result of a meticulously designed regulatory framework that balances the need for pharmaceutical innovation with the public health imperative of accessible medicine.

At the heart of this framework lies a fundamental tension—what we might call the “affordability paradox.” The very market forces that drive down the cost of generics, namely intense price competition, can simultaneously exert immense pressure on manufacturers, potentially threatening the investments required for uncompromising quality.4 How, then, can patients, physicians, and regulators trust that a generic drug, often costing 85% less than its brand-name predecessor, is just as safe and effective?.

The answer is not found in a marketing brochure or a price tag. It is embedded in the very architecture of the manufacturing process itself. It is a system of principles, procedures, and rigorous controls known as Good Manufacturing Practice (GMP).

This report is designed for you—the strategic leader, the portfolio manager, the quality professional—to move beyond a textbook definition of GMP. We will deconstruct its critical role not as a regulatory burden, but as the non-negotiable foundation of the entire generic drug value proposition. We will explore how mastering GMP is a profound competitive advantage, a crucial risk mitigation tool, and the key to unlocking sustainable success in an industry where trust is the most valuable currency. Forget thinking of GMP as a cost center; it’s time to understand it as the very engine of your business.

Section 1: The Symbiotic Relationship: Why GMP is the Bedrock of the Generic Drug Industry

To truly grasp the importance of GMP, we must first understand the unique promise of a generic drug. It is a promise of sameness, of therapeutic equivalence, delivered at a fraction of the cost. But a promise is only as good as the proof that backs it up. In the world of generics, GMP is that proof.

Defining the Generic Proposition: More Than Just a Copy

A generic drug is often casually referred to as a “copy” of a brand-name drug, but this term belies the rigorous scientific and regulatory standards it must meet. A generic drug is, by definition, a pharmaceutical product that is proven to be a therapeutic equivalent to an existing, approved brand-name drug, known as the Reference Listed Drug (RLD).7

Regulatory bodies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) mandate that a generic drug must have the same:

- Active Pharmaceutical Ingredient (API): The component that produces the intended therapeutic effect.6

- Strength: The amount of active ingredient in a given dosage form.9

- Dosage Form: Whether it’s a tablet, capsule, or injectable.7

- Route of Administration: How the drug is taken, such as orally or topically.7

- Intended Use and Labeling: The conditions it is approved to treat, with some exceptions for patented uses.

While inactive ingredients like fillers, binders, and colorings can differ, the manufacturer must prove these differences do not affect the drug’s performance, safety, or effectiveness.6 Even the physical appearance—the shape and color—is often required to be different due to trademark laws.7

The Scientific Cornerstone: Bioequivalence

The lynchpin of the generic drug approval process is the concept of bioequivalence (BE). Since the brand-name drug has already undergone extensive clinical trials to prove its safety and efficacy, a generic manufacturer does not need to repeat these costly and time-consuming studies.7 Instead, they must scientifically demonstrate that their product performs in the same way in the human body.

Bioequivalence is defined as “the absence of a significant difference in the rate and extent to which the active ingredient… becomes available at the site of drug action”. In practice, this is typically demonstrated by conducting a study in a small group of healthy volunteers. They are given both the generic and the brand-name drug on separate occasions, and blood samples are drawn at regular intervals to measure the concentration of the drug in their bloodstream over time.

Two key pharmacokinetic parameters are measured:

- Cmax: The maximum concentration of the drug in the blood. This indicates the rate of absorption.

- AUC (Area Under the Curve): The total exposure to the drug over time. This indicates the extent of absorption.

For the FDA to approve a generic, the 90% confidence interval for the ratio of the generic’s average AUC and Cmax to the brand’s must fall entirely within the limits of 80% to 125%. This statistical window is often misunderstood as allowing a generic’s potency to vary widely. This is incorrect. The statistical requirement is stringent, forcing the average performance of the generic to be very close to the brand. In fact, a comprehensive review of thousands of bioequivalence studies found that the average difference in absorption (AUC) between generic and brand-name drugs was a mere 3.5%—a difference that is not clinically significant.6

The Regulatory Pathway: The Abbreviated New Drug Application (ANDA)

This proof of bioequivalence is the centerpiece of the Abbreviated New Drug Application (ANDA), the regulatory submission made to the FDA to market a generic drug.14 The pathway is “abbreviated” precisely because it leverages the innovator’s original safety and efficacy data, replacing duplicative clinical trials with BE studies.11 This streamlined process, established by the landmark Drug Price Competition and Patent Term Restoration Act of 1984 (commonly known as the Hatch-Waxman Act), is the fundamental mechanism that makes affordable generics possible.11 It transforms the manufacturer’s challenge from one of high-risk scientific

discovery to one of meticulous scientific demonstration.

The GMP Mandate: The Non-Negotiable Foundation for Proving Sameness

Here we arrive at the central question: if the ANDA process hinges on a single bioequivalence study, how can regulators, doctors, and patients be certain that the ten-millionth tablet produced is identical in quality and performance to the few dozen used in that pivotal study?

The answer is Good Manufacturing Practice.

GMP is the legally enforceable system of minimum requirements for the methods, facilities, and controls used in the manufacturing, processing, and packing of a drug product.18 It is not a suggestion or a best practice guide; it is the law. The core principle of GMP is that quality cannot be tested into a finished product; it must be built into the design and manufacturing process at every single step.20

The Food and Drug Administration (FDA) regulates the quality of pharmaceuticals very carefully. The main regulatory standard for ensuring pharmaceutical quality is the Current Good Manufacturing Practice (CGMP) regulations for human pharmaceuticals… A consumer usually cannot detect (through smell, touch, or sight) that a drug product is safe or if it will work. While CGMP requires testing, testing alone is not adequate to ensure quality.

— U.S. Food and Drug Administration

Both brand-name and generic drug manufacturers are held to the exact same stringent GMP standards.6 The FDA regulations are referred to as

Current Good Manufacturing Practice (cGMP). The “c” is a critical reminder that the systems and technologies used must be up-to-date and reflect the current state of scientific understanding and risk management.19 A process that was considered state-of-the-art 20 years ago may be woefully inadequate today.

The relationship between the ANDA and cGMP is not merely parallel; it is deeply symbiotic and causal. The streamlined nature of the ANDA—its very existence—is predicated on the regulator’s absolute confidence in the manufacturer’s cGMP compliance. By forgoing the need for repeated large-scale clinical trials, the regulatory burden of proof for consistency, safety, and quality shifts almost entirely to the manufacturing process itself.

Consider the logical chain:

- The ANDA pathway allows a generic to come to market based on a bioequivalence study, which demonstrates that a specific batch of the generic drug performs the same as the brand.

- This creates an immense regulatory challenge: ensuring that every subsequent batch—produced potentially for years, across different equipment, with different lots of raw materials—is also bioequivalent.

- Directly testing every batch in human subjects is impossible and impractical.

- Therefore, regulators must rely on a proxy for consistent bioequivalence. That proxy is a robust, validated, and meticulously controlled manufacturing process.

- cGMP provides the detailed, legally binding framework for that process. It is the system of controls—covering everything from the air quality in the facility to the training of the operator to the calibration of the tablet press—that gives the FDA confidence that the process is in a “state of control” and will consistently produce a product with the same critical quality attributes as the batch used in the BE study.18

In this light, cGMP is not just a set of rules to follow. It is the enabling mechanism that makes the entire generic drug model viable and trustworthy. For a generic company, whose business is not drug discovery but manufacturing excellence, mastery of cGMP is the core competency. A failure in cGMP is not just a compliance issue; it is a fundamental failure of the company’s core mission and a direct threat to the trust that underpins its license to operate. Any drug produced in a facility that fails to comply with cGMP is considered “adulterated” under the law, regardless of what the final test results say, because the assurance of quality has been compromised at its source.23

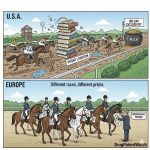

Section 2: Deconstructing the Global GMP Rulebook: A Tale of Two Agencies

For any generic manufacturer with ambitions beyond a single domestic market, navigating the global regulatory landscape is a paramount challenge. While the core principles of GMP are internationally recognized, the specific regulations and enforcement philosophies of the world’s two largest regulatory bodies—the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA)—have crucial differences. Understanding these nuances is essential for designing a quality system that is not only compliant but also efficient and globally scalable.

The U.S. FDA Framework: A Deep Dive into 21 CFR Parts 210 & 211

In the United States, the Current Good Manufacturing Practice (cGMP) regulations for pharmaceuticals are codified in Title 21 of the Code of Federal Regulations (CFR). For generic drug manufacturers, two parts are of central importance: 21 CFR Part 210 and 21 CFR Part 211. Together, they form the gold standard for pharmaceutical manufacturing in the U.S. and are rigorously enforced by the FDA through facility inspections and audits.

21 CFR Part 210: The General Provisions

Part 210 serves as the introduction to the cGMP framework. It is concise but powerful, laying out the fundamental principles and definitions that govern the more detailed requirements in Part 211. Its key functions are:

- Defining Scope and Status: It establishes that these regulations contain the minimum cGMP requirements and clarifies that failure to comply shall render a drug “adulterated” under the Federal Food, Drug, and Cosmetic Act.24 This is a critical legal point: a product’s quality is defined by its manufacturing process, not just its final attributes.

- Applicability: It clarifies that the regulations apply to the manufacturing, processing, packing, or holding of all drug products, both prescription and over-the-counter.25

- Definitions: It provides official definitions for essential terms that are used throughout the regulations, such as “batch,” “component,” “active ingredient,” and, critically, the “quality control unit”.

21 CFR Part 211: The Detailed Mandates for Finished Pharmaceuticals

Part 211 is the operational heart of the FDA’s cGMP regulations. It is a comprehensive set of mandates that cover every aspect of the manufacturing process for finished drug products.27 For a generic manufacturer, understanding these subparts is not just a matter for the quality department; it dictates the design of facilities, the structure of the organization, and the flow of daily operations. Let’s walk through the most critical subparts:

- Subpart B – Organization and Personnel: This subpart places immense authority and responsibility on the Quality Control Unit (QCU). The QCU must be an independent entity within the organization with the absolute authority to approve or reject all components, in-process materials, procedures, specifications, and finished drug products. It also mandates that all personnel involved in manufacturing have the necessary education, training, and experience to perform their assigned functions, with training being a continuous and documented process.30

- Subpart C – Buildings and Facilities: This section requires that facilities be of suitable size, construction, and location to facilitate proper cleaning, maintenance, and operations. It mandates adequate space to prevent mix-ups and cross-contamination, as well as appropriate controls for lighting, ventilation, air filtration, plumbing, and sanitation.25

- Subpart D – Equipment: Equipment must be designed, constructed, and located to be suitable for its intended use. It must be easy to clean and maintain to prevent contamination. This subpart also mandates rigorous, documented procedures for equipment calibration, inspection, and maintenance.25

- Subpart E – Control of Components and Drug Product Containers and Closures: This is the gatekeeper function. It requires written procedures for the receipt, identification, storage, handling, sampling, testing, and approval or rejection of all incoming materials.28 All materials must be stored under quarantine until they are tested and released by the QCU.

- Subpart F – Production and Process Controls: This subpart demands written procedures for every step of production to ensure that drug products have the identity, strength, quality, and purity they claim to possess.28 It requires the establishment of in-process controls (e.g., checking tablet weight variation, dissolution time) and the validation of manufacturing processes to ensure they are reproducible and reliable.

- Subpart G – Packaging and Labeling Control: Mislabeling is one of the most serious and common causes of drug recalls. This subpart requires strict procedures for the receipt, storage, and issuance of labels and labeling materials. It mandates 100% examination of labeling for finished products and requires line clearance procedures to ensure that materials from a previous batch are completely removed before a new batch begins.25

- Subpart J – Records and Reports: If it wasn’t documented, it didn’t happen. This subpart mandates the creation and maintenance of detailed records for every aspect of manufacturing. This includes complete batch production and control records for each batch, equipment cleaning logs, component records, and distribution records. It also requires procedures for handling customer complaints and conducting annual product quality reviews.28

- Subpart I – Laboratory Controls: This section requires the establishment of scientifically sound specifications, standards, and test procedures to ensure that components and finished products conform to appropriate standards of identity, strength, quality, and purity. It also covers requirements for stability testing to determine appropriate storage conditions and expiration dates.

The European EMA Framework: Navigating EudraLex Volume 4

In the European Union, the regulatory framework is known as EudraLex, a comprehensive collection of rules and regulations for medicinal products for human and veterinary use. For manufacturers, the most critical document is EudraLex Volume 4: Good Manufacturing Practice (GMP) Guidelines.34

While the FDA’s regulations are presented as a legal code, EudraLex Volume 4 is structured more like a detailed guidance manual, though its principles are legally binding once transposed into the national laws of EU member states. Its structure is logical and hierarchical:

- Part I: Basic Requirements for Medicinal Products: This is the core of the GMP guidelines, organized into nine chapters that parallel many of the FDA’s subparts but with a distinct philosophical approach.36

- Chapter 1: Pharmaceutical Quality System

- Chapter 2: Personnel

- Chapter 3: Premises and Equipment

- Chapter 4: Documentation

- Chapter 5: Production

- Chapter 6: Quality Control

- Chapter 7: Outsourced Activities

- Chapter 8: Complaints and Product Recall

- Chapter 9: Self Inspection

- Part II: Basic Requirements for Active Substances used as Starting Materials: This section provides specific GMP guidance for API manufacturing, aligning with the principles of the internationally harmonized ICH Q7 guideline.35

- Annexes: These are a crucial part of the EU GMP framework, providing detailed, specific guidance on a wide range of topics. For a generic manufacturer, key annexes include:

- Annex 1: Manufacture of Sterile Medicinal Products

- Annex 11: Computerised Systems

- Annex 15: Qualification and Validation

- Annex 16: Certification by a Qualified Person and Batch Release.35

Two concepts are particularly central to the European approach and represent key differences from the U.S. system:

- The Qualified Person (QP): The EU legal framework places the ultimate responsibility for certifying that each batch of a medicinal product meets all legal and quality requirements on a specific, named individual known as the Qualified Person. Before a batch can be released for sale in the EU, a QP must personally sign off on it, attesting that it was manufactured in accordance with GMP and the terms of its Marketing Authorisation. This places a significant personal legal liability on the QP, a concept that does not have a direct equivalent in the U.S. system, where responsibility rests more corporately with the Quality Control Unit.36

- Explicit Integration of Quality Risk Management (QRM): While the FDA strongly encourages QRM based on ICH Q9 principles, the EU GMP guidelines explicitly embed QRM into the fabric of the Pharmaceutical Quality System (Chapter 1). It is not just a good idea; it is a required methodology for proactively identifying, evaluating, and controlling potential risks to product quality throughout the lifecycle.34

Harmonization and Divergence: A Comparative Analysis for Global Manufacturers

For a generic company aiming to market products in both the U.S. and the EU, simply complying with one set of regulations is not enough. While the overarching goals of GMP are identical—ensuring product safety, quality, and efficacy—the subtle yet significant differences in regulatory philosophy and specific requirements can create major operational challenges. A successful global strategy requires designing a single, robust quality system that satisfies the highest common denominator of all target markets.

The differences are not merely academic; they drive tangible strategic decisions. For example, the EU’s focus on the personal liability of the Qualified Person often leads to a more cautious and meticulous batch review and release process. The explicit requirement for formal Quality Risk Management in the EU framework forces a more structured and documented approach to decision-making compared to what might be acceptable in a purely U.S.-focused operation.

This reality has a profound impact on a generic company’s operational strategy. It is both impractical and risky to maintain two separate quality systems for two different markets. The only viable path is to create a unified, global Pharmaceutical Quality System that incorporates the strictest elements of both frameworks. This means a company marketing in both regions will likely have a “QP-like” final review and certification process for all batches, even those destined for the U.S. It will embed formal QRM methodologies into its change control, deviation management, and validation processes. This approach may increase the upfront cost and complexity of the quality system, but the payoff is immense. It creates a single, highly resilient, and globally defensible standard of operation. This harmonization minimizes the risk that a compliance failure in one jurisdiction will trigger a cascade of regulatory actions in others, thereby protecting global market access and brand reputation.

The following table provides a strategic overview of some of the most critical differences for generic manufacturers.

| Feature/Requirement | FDA cGMP (21 CFR 211) | EU GMP (EudraLex Vol. 4) | Strategic Implication for Generics |

| Final Batch Release Authority | Quality Control Unit (QCU) has ultimate authority. Responsibility is corporate. | The Qualified Person (QP) personally certifies each batch. Responsibility is individual and legally binding.36 | Global manufacturers must implement a release process with the rigor and personal accountability of a QP system for all markets to ensure a single, high standard. |

| Quality Risk Management (QRM) | Strongly encouraged as part of a modern quality system, based on ICH Q9. | Explicitly required and integrated into Chapter 1 (Pharmaceutical Quality System). A foundational element.34 | A global PQS must be built on formal, documented QRM principles to be compliant in the EU, which elevates the standard for U.S. operations as well. |

| Process Validation | Emphasizes a flexible, science-based lifecycle approach (Design, Qualification, Verification). | Traditionally more prescriptive (e.g., minimum of three consecutive successful batches), though now also embracing the lifecycle concept. | Companies often default to the more prescriptive “three-batch” model for initial validation as it is universally accepted, even if not strictly required by the FDA. |

| API GMP Requirements | Enforced through inspections and reliance on ICH Q7. | Part II of EudraLex Vol. 4 provides specific GMP for APIs. Requires a “written confirmation” from the competent authority of the exporting country for imported APIs. | The supply chain for APIs must be robustly documented to meet EU import requirements, which benefits global supply chain integrity and traceability. |

| Computer System Validation | Governed by 21 CFR Part 11, with a strong focus on the integrity of electronic records and signatures. | Governed by Annex 11, which takes a broader lifecycle approach to the validation of the entire computerized system. | Systems must be validated to meet both the data integrity focus of Part 11 and the lifecycle management scope of Annex 11, requiring a comprehensive validation package. |

| Cross-Contamination Control | General principles of prevention through facility design and cleaning validation are required.25 | More explicit guidance, including the mandatory use of health-based exposure limits (HBELs) for risk assessment in shared facilities.35 | The EU’s requirement for toxicological HBEL calculations is becoming the global standard, forcing all manufacturers to adopt a more scientific, data-driven approach to cleaning validation. |

Section 3: Beyond Compliance: Building a Resilient Pharmaceutical Quality System (PQS)

Adhering to the detailed rules of cGMP is the price of entry into the pharmaceutical market. However, truly successful and resilient generic manufacturers understand that compliance is not the goal; it is the outcome of a much deeper commitment to quality. This commitment is embodied in the Pharmaceutical Quality System (PQS), a comprehensive framework that moves beyond a reactive, checklist-based approach to a proactive, lifecycle-oriented management of quality.

Introducing ICH Q10: The Blueprint for a Modern PQS

The most influential model for a modern PQS is outlined in the ICH Q10: Pharmaceutical Quality System guideline.42 Developed by the International Council for Harmonisation, which brings together regulatory authorities and pharmaceutical industry experts from Europe, Japan, and the U.S., ICH Q10 provides a harmonized model for quality management.

It’s crucial to understand what ICH Q10 is—and what it isn’t. It does not introduce new regulations beyond the existing GMP requirements. Instead, it provides a holistic framework that integrates GMP with established quality management concepts, such as those found in the ISO 9000 series of standards.43 The primary goal of ICH Q10 is to create a system that fosters

innovation and continual improvement, strengthening the link between pharmaceutical development and manufacturing activities. For a generic manufacturer, this means building a system that not only ensures compliance today but is also agile enough to adapt to new products, new technologies, and evolving regulatory expectations tomorrow.

The Four Pillars of the PQS Lifecycle: From Development to Discontinuation

ICH Q10 is revolutionary because it applies the PQS across the entire lifecycle of a product. This is particularly relevant for generic companies that manage a diverse portfolio of products, each at a different stage of its commercial life.42 The PQS provides a consistent management framework across four key stages:

- Pharmaceutical Development: Quality begins here. The PQS ensures that the goal of development is not just to create a product that passes a bioequivalence study, but to design a robust and reproducible manufacturing process. This stage involves developing the drug substance, the formulation, the manufacturing process, and the analytical methods needed to control it. The knowledge gained here is foundational for the entire lifecycle.

- Technology Transfer: This is a critical and often high-risk stage for generic manufacturers, involving the transfer of a product and its process from a development lab to a commercial manufacturing site, or between different manufacturing sites. The PQS manages this transfer to ensure that the process knowledge is successfully scaled and implemented, preventing costly failures during the first commercial campaigns.42

- Commercial Manufacturing: This is the traditional domain of GMP. Within an ICH Q10 framework, the PQS ensures that a “state of control” is established and maintained. It provides the systems for monitoring process performance and product quality, identifying and evaluating opportunities for improvement, and ensuring a reliable supply of product.

- Product Discontinuation: Even the end of a product’s life must be managed. The PQS ensures an orderly discontinuation process, including the management of ongoing stability studies and the proper retention of documentation and samples as required by regulations.

Management’s Role: Cultivating a Proactive Quality Culture

A PQS cannot be delegated solely to the Quality Assurance department. Its success is fundamentally dependent on the active leadership and commitment of senior management.38 ICH Q10 explicitly outlines management responsibilities, which include defining quality policy, providing adequate resources, and actively participating in management review of the PQS to ensure its continuing suitability and effectiveness.

This leadership fosters a proactive quality culture, which is supported by two key “enablers” described in ICH Q10:

- Knowledge Management: This involves a systematic approach to acquiring, analyzing, storing, and disseminating information related to products, processes, and components. For a generic company, this means leveraging data from development, manufacturing, and post-market surveillance to make scientifically sound, risk-based decisions.

- Quality Risk Management (QRM): As outlined in ICH Q9, QRM is a proactive process for the assessment, control, communication, and review of risks to the quality of the drug product across its lifecycle. It provides a formal methodology for answering the questions: “What might go wrong?”, “What is the likelihood it will go wrong?”, and “What are the consequences?”.

The operational elements of the PQS—the tools that drive daily activity and improvement—include robust systems for monitoring process performance, investigating deviations and implementing effective Corrective and Preventive Actions (CAPA), managing changes through a formal change management system, and conducting periodic management reviews of key quality metrics.42

Implementing a PQS based on the ICH Q10 model represents a significant philosophical shift. Traditional GMP compliance can often be reactive; a deviation occurs, an investigation is conducted, and a corrective action is implemented. The PQS, by contrast, is designed to be proactive and predictive. It transforms GMP from a set of static rules into a dynamic, learning system.

Here’s how that transformation works in practice: In a basic GMP environment, the focus might be on simply following a standard operating procedure (SOP) and documenting that it was followed. In an ICH Q10-driven PQS, the system compels the organization to ask deeper questions: Is this SOP the most effective way to control the critical quality attributes of our product? What process data do we have to support this? What are the potential risks if we deviate, and how can we mitigate them?

By embedding Knowledge Management and QRM, the PQS creates powerful feedback loops. Data from a CAPA investigation doesn’t just resolve a single incident; it is fed back into the organization’s collective knowledge base. This knowledge can then be used to improve the manufacturing process itself, update training programs, or even inform the development of future products, preventing similar issues from ever occurring. For a generic manufacturer operating on thin margins, this systematic approach to risk reduction and continual improvement is not a luxury. It is a direct driver of business performance, reducing the frequency of costly batch failures, minimizing waste and rework, and ultimately leading to a more efficient and reliable supply chain.

Section 4: GMP in Action: A Tour of the Generic Manufacturing Floor

While the Pharmaceutical Quality System provides the overarching strategy, its effectiveness is realized through the meticulous, day-to-day execution of GMP principles on the manufacturing floor. These principles touch every aspect of production, from the people who perform the work to the environment in which they work and the materials they use. For generic manufacturers, excellence in these operational areas is the tangible expression of their commitment to quality.

The Human Element: Personnel Qualification, Training, and Hygiene

Ultimately, even the most advanced facility is only as good as the people who operate it. Human error is a leading cause of quality deviations, making personnel management a cornerstone of GMP.

- Qualification and Competency: The regulations are unequivocal: every individual engaged in the manufacture, processing, packing, or holding of a drug product must possess the necessary combination of education, training, and experience to perform their assigned functions correctly.29 This applies to everyone, from the line operator to the senior supervisor.

- Continuous Training: GMP training is not a one-time event. Regulations mandate that training be conducted by qualified individuals on a continuing basis and with sufficient frequency to ensure employees remain familiar with the cGMP requirements applicable to them.29 This includes initial training upon hiring, specific training for new or revised procedures, and annual GMP refresher courses for all relevant staff.48 The effectiveness of this training must be periodically assessed, and all training activities must be meticulously documented.49

- Hygiene and Attire: To protect the product from microbial and particulate contamination, strict personal hygiene standards are enforced. This includes prohibitions on eating, drinking, or smoking in manufacturing areas. Personnel are required to wear appropriate protective garments, such as gowns, hair nets, and gloves, and must be trained on proper hand-washing and gowning procedures.20

- Adequate Staffing: A subtle but critical requirement is the mandate for an adequate number of qualified personnel to perform and supervise all operations. Understaffing can lead to rushed work, missed checks, and an increased likelihood of errors, making it a significant compliance risk.

The Physical Plant: Facility and Equipment Design, Qualification, and Maintenance

The physical environment and the tools used for manufacturing are the next critical layer of control. They must be designed and maintained to prevent errors and protect product quality.

- Facility Design: Pharmaceutical facilities must be located, designed, constructed, adapted, and maintained to suit the operations being carried out.25 The layout must be logical to prevent mix-ups between different products or components. Surfaces must be smooth and easy to clean. Crucially, there must be adequate control over the environment, including air handling systems (with appropriate filtration), temperature, humidity, and lighting, to protect the product.32

- Equipment Suitability: All equipment used in manufacturing must be of the appropriate design, adequate size, and suitably located to facilitate its intended use, cleaning, and maintenance.25 Surfaces that come into contact with the product must not be reactive, additive, or absorptive so as to alter the quality of the drug.

- Qualification and Validation: Equipment cannot simply be installed and used. It must undergo a formal, documented process of qualification to prove that it is fit for its intended purpose. This is typically a multi-stage process:

- Design Qualification (DQ): Verifying that the design of the equipment is suitable for the intended purpose.

- Installation Qualification (IQ): Verifying that the equipment has been installed correctly according to the manufacturer’s specifications and design requirements.

- Operational Qualification (OQ): Verifying that the equipment operates as intended throughout its specified operating ranges.

- Performance Qualification (PQ): Verifying that the equipment, as installed and operated, consistently performs as intended and produces a product that meets its specifications.

- Maintenance and Calibration: There must be written programs and schedules for the routine calibration of all instruments and the preventive maintenance of all equipment.32 All calibration and maintenance activities must be documented in equipment logs. This ensures that a scale is always weighing accurately and a temperature probe is always reading correctly, preventing process deviations.

The Starting Line: Sourcing and Quality Control of APIs and Raw Materials

The quality of a finished drug product can be no better than the quality of its starting materials. For generic manufacturers, who often rely on a global network of suppliers, the control of incoming components is a critical control point.

- Supplier Qualification: Before a company can purchase an API or a critical excipient from a supplier, it must first qualify that supplier. This involves a thorough assessment of the supplier’s quality systems, often including an on-site audit, to ensure they can reliably provide material that meets the required specifications. The reliability of a supplier’s own Certificate of Analysis (CoA) must be established through periodic verification testing.

- Receipt and Testing: GMP requires robust written procedures for the entire lifecycle of a component, from its arrival at the warehouse to its use in production.28 Upon receipt, each container must be visually examined for damage and correct labeling. The material must then be placed in quarantine and sampled by the Quality Control unit. At a minimum, an identity test must be performed on each lot of each component to confirm it is what it claims to be. Further testing for purity, strength, and quality is performed against pre-approved specifications before the material is released for use.28

- API Source Changes: The API is the most critical component. Because different manufacturing processes can result in different impurity profiles, changing the source of an API is considered a major change with a high potential to impact the drug product’s quality and safety. In the U.S., such a change requires the submission of a Prior Approval Supplement (PAS) to the FDA, which must be approved before the new API source can be used commercially.59 This involves providing extensive data demonstrating the comparability of the new API and its performance in the finished drug product.

The Core Process: Process Validation, In-Process Controls, and Cross-Contamination Prevention

With qualified personnel, a suitable facility, and high-quality materials, the focus shifts to the manufacturing process itself. The goal is to ensure the process is robust, controlled, and free from contamination.

- Process Validation: This is the cornerstone of process control. Process validation is the collection and evaluation of data, from the process design stage through commercial production, which establishes scientific evidence that a process is capable of consistently delivering a quality product. The FDA advocates a three-stage lifecycle approach:

- Stage 1: Process Design: The commercial manufacturing process is defined based on knowledge gained through development and scale-up activities.

- Stage 2: Process Qualification: The process design is evaluated to determine if the process is capable of reproducible commercial manufacturing. This includes qualification of the facility and equipment (as discussed above) and performance qualification runs.

- Stage 3: Continued Process Verification: Ongoing assurance is gained during routine production that the process remains in a state of control.

Insufficient process validation is a direct precursor to manufacturing failures. Without a deep, scientific understanding of the process and its sources of variability, a manufacturer cannot ensure consistent control. A minor, unmonitored fluctuation in a critical parameter—such as mixing time or drying temperature—can lead to a batch that fails its quality specifications. This results in costly investigations, rejected batches, and, in the worst-case scenario, product recalls. Therefore, robust process validation is not a mere documentation exercise; it is a fundamental risk-mitigation strategy that underpins manufacturing reliability.

- In-Process Controls (IPCs): These are checks performed at critical steps during production to monitor the process and ensure the product is conforming to its specifications. Examples include checking the weight uniformity of tablets as they are being compressed, measuring the pH of a solution during mixing, or testing the disintegration time of capsules.23 If an IPC result trends toward an established limit, operators can adjust the process before the batch goes out of specification.

- Cross-Contamination Prevention: In multi-product facilities, which are the norm for generic manufacturers, preventing the carryover of materials from one product to another is a paramount concern. Cross-contamination can pose serious health risks, especially with highly potent or sensitizing compounds like beta-lactam antibiotics or hormones. Prevention is a multi-faceted strategy that includes:

- Facility Design: Using dedicated, self-contained facilities for particularly hazardous products. Implementing segregated production areas and carefully designed air handling systems to prevent the movement of dust and contaminants.20

- Cleaning Validation: Developing and validating rigorous cleaning procedures for all shared equipment to demonstrate that residues of the previous product are removed to a safe, scientifically determined level.52

- Procedural Controls: Implementing “campaign” manufacturing (producing multiple batches of one product before switching to another) and strict line clearance procedures to verify that all materials and documentation from the previous run have been removed before a new one begins.62

Section 5: The Paper and Digital Trail: Ensuring Impeccable Data Integrity

In the highly regulated world of pharmaceutical manufacturing, the adage “if it wasn’t documented, it didn’t happen” is an absolute truth. Documentation is the backbone of GMP compliance. It provides the objective evidence that a product was made according to its validated process and approved procedures. In recent years, as manufacturing has become more digitized, the focus on the integrity of this data—whether on paper or in a computer system—has become a primary concern for regulators worldwide.

The Sanctity of the Batch Record: Creating an Unimpeachable History of Production

The single most important document in pharmaceutical manufacturing is the Batch Production Record (BPR), also known as the Batch Manufacturing Record (BMR). The BPR is the complete, chronological, and legally binding history of the production and control of a single batch of a drug product. It is derived from a master template, the Master Production Record (MPR), which contains the approved formula and detailed instructions for producing a given product.

The BPR is the crown witness to a batch’s quality. It must be prepared for every batch produced and must contain complete information, including :

- An accurate reproduction of the relevant MPR, checked for accuracy.

- Dates and times of each significant manufacturing step.

- Identification of major equipment and production lines used.

- Specific identification (including lot numbers) of each component and in-process material used.

- Weights and measures of all components, often requiring a second-person verification.

- Results of all in-process and laboratory control tests.

- Inspection of the packaging and labeling area before and after use.

- A statement of the actual yield compared to the theoretical yield at key stages.

- Complete labeling control records, including specimens of all labels used.

- Documentation of any deviations or investigations that occurred during production.

- Signatures or initials of the individuals who performed and checked each critical step.66

Before a batch can be released for distribution, the entire BPR must be thoroughly reviewed and formally approved by the Quality Control Unit to ensure that all steps were completed correctly, all specifications were met, and any deviations were adequately investigated and resolved.28 This review is the final gatekeeper that prevents a non-conforming batch from reaching the market.

Navigating the Digital Realm: Understanding 21 CFR Part 11 for Electronic Records and Signatures

As manufacturers increasingly adopt electronic systems—from Laboratory Information Management Systems (LIMS) to fully electronic batch records (eBRs)—the need to ensure the trustworthiness of digital data has become critical. In the U.S., this is governed by 21 CFR Part 11, which establishes the FDA’s criteria for accepting electronic records and electronic signatures as equivalent to their paper and handwritten counterparts.40

Part 11 is not just an IT requirement; it is a fundamental GMP requirement for any company using computer systems to manage quality-critical data. Its core mandates are designed to ensure data authenticity, integrity, and confidentiality. Key requirements include:

- System Validation: The computer system must be validated to ensure it performs its intended function accurately, reliably, and consistently.70

- Secure Audit Trails: The system must generate a secure, computer-generated, time-stamped audit trail that independently records all operator actions that create, modify, or delete an electronic record. This trail must be non-editable and must be retained for as long as the underlying record.70 This provides complete traceability of all data changes.

- Access Controls: System access must be limited to authorized individuals. This requires unique user IDs and passwords for each person (no shared accounts) and a permissions structure that ensures users can only perform functions relevant to their roles.70

- Electronic Signatures: When used, electronic signatures must be as legally binding as handwritten ones. They must be unique to one individual, require at least two distinct identification components (e.g., ID and password), and be securely linked to their respective electronic record so that any change to the record after signing would be detected.40

The ALCOA+ Principles: The Gold Standard for Trustworthy Data

Underpinning both paper-based documentation and 21 CFR Part 11 is a set of fundamental principles for data integrity known as ALCOA+. This acronym has become the universal shorthand used by regulators to assess the quality and trustworthiness of a company’s data.

The original five principles of ALCOA are:

- Attributable: All data must be traceable to the individual who generated it and when it was generated. This is achieved through signatures, initials, dates, and secure user IDs.73

- Legible: Data must be readable and permanent throughout the record’s retention period. This means using indelible ink on paper and ensuring electronic data can be retrieved in a human-readable format.73

- Contemporaneous: Data must be recorded at the time the work is performed. Backdating or recording data from memory is a serious violation of data integrity.73

- Original: The record must be the original source of the data or a certified “true copy.” Data should not be transcribed from scrap paper to an official record later, as this introduces the risk of error.72

- Accurate: The data must be correct, truthful, and reflect the actual observation or event. Any changes made to an original entry must not obscure the original data and must be documented with a reason, signature, and date.72

In recent years, the concept has been expanded to ALCOA+, adding four more critical attributes:

- Complete: All data, including any repeat or re-analysis, must be present. Nothing should be deleted or hidden.73

- Consistent: Data must be recorded chronologically, with date and time stamps in the expected sequence.73

- Enduring: Data must be maintained and protected in a durable format for the entire required retention period.73

- Available: Data must be readily accessible for review, audit, or inspection throughout its lifecycle.72

The convergence of these principles—the detailed requirements of batch records, the technical controls of 21 CFR Part 11, and the guiding philosophy of ALCOA+—creates a powerful framework for data governance. In today’s globalized and cost-pressured generic industry, this framework has evolved from a simple matter of good record-keeping into a central pillar of business risk management.

The geographic and organizational distance inherent in global supply chains increases the risk of data integrity lapses, whether through unintentional error or deliberate manipulation. FDA warning letters are replete with examples of data integrity failures discovered at overseas facilities, such as falsified laboratory results or deleted data.76 A single, credible finding of data manipulation can cast doubt on the validity of

all data generated by a facility. This can lead to catastrophic consequences, including import alerts that block all products from entering the U.S., forced product recalls, and a complete erosion of regulatory and market trust.78

Therefore, investing in robust, validated electronic systems that enforce ALCOA+ principles by design—with features like unalterable audit trails, granular access controls, and secure electronic signatures—is not merely an IT expense. It is a strategic investment in corporate survival. It provides objective, verifiable proof of quality that transcends geography, withstands intense regulatory scrutiny, and directly protects a company’s revenue, market access, and reputation.

Section 6: The High Stakes of Non-Compliance: Challenges and Consequences

While the principles of GMP are clear, implementing them flawlessly in the real world is a formidable challenge, especially for generic drug manufacturers. The industry operates at the confluence of intense economic pressure, complex global logistics, and ever-evolving regulatory scrutiny. A failure to navigate these challenges can have severe and far-reaching consequences, impacting not only a company’s bottom line but also its very license to operate.

The Generic Squeeze: How Intense Cost Pressure Challenges Quality Investment

The fundamental business model of the generic drug industry creates a powerful and persistent challenge to GMP compliance. The “affordability paradox” means that the very mechanism that delivers value to the healthcare system—fierce price competition—simultaneously squeezes the profit margins needed to invest in top-tier quality systems.

- Price Erosion: The entry of the first generic competitor typically cuts the price of a drug by 30-40% compared to the brand. With the entry of multiple competitors, prices can plummet by 70-95%, reducing once-profitable drugs to near-commodity status.4

- Disincentive for Investment: These razor-thin margins create a powerful disincentive for manufacturers to make significant capital investments in areas like facility modernization, advanced manufacturing technologies (like continuous manufacturing), or building supply chain redundancy.5 The focus can shift from proactive quality improvement to reactive, minimum-level compliance.

- Root Cause of Drug Shortages: This economic pressure is a well-documented root cause of drug shortages, particularly for older, sterile injectable products that are critical for hospital care.80 When profitability becomes unsustainable, manufacturers may choose to discontinue a product line rather than invest in necessary facility upgrades, leading to a fragile supply chain with few, if any, alternate suppliers.4

Navigating the Global Supply Chain Maze: Risks and Vulnerabilities

The modern pharmaceutical supply chain is a sprawling global network, which introduces significant complexity and risk into maintaining end-to-end GMP control.

- Concentration Risk: A vast proportion of the world’s Active Pharmaceutical Ingredients (APIs) and their key starting materials are manufactured in a small number of countries, primarily China and India.82 This geographic concentration makes the entire global supply chain vulnerable to disruptions from a single point of failure, whether it’s a geopolitical event, a natural disaster, or a major quality failure at a key facility.

- Oversight of Contract Partners: Many generic companies rely on a network of Contract Manufacturing Organizations (CMOs) and external testing laboratories. While outsourcing can provide cost and capacity benefits, it also extends the company’s GMP responsibility. The marketing authorization holder is ultimately responsible for the quality of the product, making robust supplier qualification and ongoing oversight of all contract partners an absolute necessity.

- Lack of Transparency: The multi-layered nature of the supply chain can create a lack of transparency. A generic company might buy its API from a supplier in India, who in turn buys their key intermediates from a manufacturer in China. Problems at the Chinese facility can directly impact the quality of the final drug product, but without deep supply chain visibility, these risks can remain hidden until it’s too late.

When Things Go Wrong: Understanding FDA Form 483s, Warning Letters, and Recalls

When a company’s GMP systems fail to withstand regulatory scrutiny, the consequences are swift and severe. The FDA has a well-defined escalation path for enforcement actions.

- FDA Form 483: At the conclusion of a GMP inspection, if the FDA investigator has observed conditions that may constitute violations of the Food, Drug, and Cosmetic Act, they will issue a Form 483, “Inspectional Observations”. This is not a final determination of non-compliance, but a formal list of concerns. A company’s response to a 483 is critical; a prompt, thorough, and scientifically sound response that includes a robust Corrective and Preventive Action (CAPA) plan can often prevent further escalation. Common 483 observations for generic facilities frequently cite deficiencies in the responsibilities of the quality unit, inadequate investigation of discrepancies, failure to follow written procedures, and issues with equipment cleaning and process validation.77

- Warning Letters: If a company’s response to a 483 is deemed inadequate, or if the initial violations are particularly egregious, the FDA may issue a formal Warning Letter. This is a serious regulatory action that indicates the agency believes the firm has significant violations and that enforcement action is possible if they are not promptly and comprehensively corrected.76 Warning Letters are publicly available and can cause significant damage to a company’s reputation. Recent trends in warning letters continue to highlight persistent issues with data integrity, inadequate process controls, and insufficient investigation into batch failures.77

- Further Enforcement Actions: Failure to address the issues in a Warning Letter can lead to more severe actions, including:

- Import Alerts: Banning the importation of all drugs from a specific facility into the U.S..

- Product Seizures and Recalls: Removing adulterated products from the market.

- Injunctions and Consent Decrees: Court orders that can force a company to halt manufacturing until major systemic problems are fixed, often under the supervision of a third-party expert, at the company’s expense.

- Criminal Charges: In the most severe cases of deliberate fraud or endangerment, the FDA can pursue criminal prosecution of both the company and responsible individuals.19

The financial and reputational costs of these actions can be devastating, far outweighing any perceived savings from cutting corners on quality.

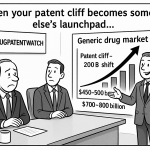

Strategic Planning with Patent Intelligence

Proactive risk management and the foundation for successful GMP compliance begin long before the first gram of API is ordered. It starts with strategic portfolio selection, a process where business development and regulatory strategy are inextricably linked. A generic company’s success depends on its ability to navigate the complex and often litigious world of pharmaceutical patents to identify viable market entry opportunities.

This is where sophisticated patent intelligence becomes an indispensable strategic tool. The decision of which product to develop is a high-stakes calculation of risk and reward. It requires a deep understanding of the brand-name drug’s patent portfolio, including the expiration dates of key patents, the potential for “patent thickets” designed to deter generic competition, and the likelihood of litigation under the Hatch-Waxman Act.

Platforms like DrugPatentWatch provide this critical business intelligence. They offer comprehensive, searchable databases of drug patents, regulatory exclusivities, patent litigation history, and potential market entry timelines.91 By leveraging such tools, a generic company can:

- Identify High-Value Opportunities: Pinpoint drugs with upcoming patent expiries and favorable market dynamics.

- Assess Litigation Risk: Analyze the patent landscape and the brand company’s history of litigation to gauge the likelihood and potential cost of a patent challenge.

- Inform Portfolio Management: Make data-driven decisions about which projects to pursue and how to allocate resources effectively.90

This strategic foresight is directly linked to a company’s ability to succeed in GMP. A well-chosen product with a clear regulatory path and a solid business case will justify the necessary investment in robust process development, high-quality facilities, and a world-class quality system. Conversely, a poorly chosen target that gets bogged down in unexpected litigation or faces unsustainable price erosion from the start may starve the project of the very resources needed to ensure GMP compliance is built in from day one. In this sense, a sound patent strategy is the first, and perhaps most critical, step in the entire GMP lifecycle.

Section 7: The Future is Now: The Evolution of GMP in the Digital Age

The foundational principles of Good Manufacturing Practice—ensuring identity, strength, quality, and purity—are timeless. However, the methods and technologies used to achieve these principles are in the midst of a profound transformation. The convergence of digital technology, advanced analytics, and a new regulatory philosophy focused on proactive quality management is reshaping the future of generic drug manufacturing. For companies looking to thrive in the coming decade, embracing this evolution is not optional; it is essential for survival and success.

Pharma 4.0: The Dawn of the Smart Generic Factory

Pharma 4.0 is the application of the fourth industrial revolution (Industry 4.0) to the pharmaceutical sector. It represents a move away from siloed, manual, and paper-based operations toward a fully integrated, automated, and data-driven “smart factory” model.93 This is not merely about modernizing equipment; it is a fundamental rethinking of how manufacturing processes are designed, controlled, and improved.

Key technologies driving Pharma 4.0 include:

- The Industrial Internet of Things (IIoT): A network of smart sensors embedded throughout the manufacturing process, collecting vast amounts of real-time data on critical process parameters like temperature, pressure, and particle size.

- Artificial Intelligence (AI) and Machine Learning (ML): Algorithms that can analyze this real-time data to optimize processes, predict equipment failures before they happen (predictive maintenance), and identify subtle deviations from the norm that could indicate a quality issue.95

- Robotics and Automation: Automating repetitive tasks to reduce human error, increase consistency, and improve efficiency.

- Cloud Computing and Big Data Analytics: Centralizing data from across the enterprise (R&D, manufacturing, supply chain) to provide a single source of truth, enabling faster, more informed decision-making.

For a generic manufacturer, the strategic business value of Pharma 4.0 is immense. It offers a pathway to overcome the inherent tensions of the “affordability paradox” by simultaneously improving quality and reducing costs. The benefits include 93:

- Quicker Time-to-Market: Digital twins and simulation models can accelerate process development and technology transfer.

- Enhanced Operational Efficiency: Predictive maintenance and optimized scheduling reduce downtime and waste.

- Improved Product Quality: Real-time process monitoring allows for the immediate detection and correction of deviations, preventing batch failures.

- Better Compliance: Automation reduces documentation errors and simplifies the preparation for regulatory audits.

From Batch to Flow: The Promise of Continuous Manufacturing

For over half a century, pharmaceutical manufacturing has been dominated by batch processing—a stepwise, start-and-stop process where materials are processed in discrete lots, with pauses and quality checks between each step. While reliable, this method can be slow, inefficient, and require a large facility footprint.

Continuous Manufacturing (CM) represents a paradigm shift. In a CM process, raw materials are continuously fed into an integrated, closed system, and the finished product emerges at the other end in a constant flow. This approach, long used in other industries like petrochemicals and food, is now being actively encouraged by the FDA and other regulators for pharmaceuticals.97

The advantages of CM are compelling:

- Increased Efficiency: CM can dramatically reduce production time from weeks or months to just days.

- Smaller Footprint: CM equipment is typically much smaller, reducing the capital cost of building new facilities.

- Enhanced Quality Assurance: The process is integrated with Process Analytical Technology (PAT)—in-line sensors that monitor critical quality attributes in real time. This allows for constant control and adjustment, ensuring a higher degree of quality consistency and enabling concepts like real-time release.

- Flexibility: A CM line can be run for short or long periods depending on demand, making it easier to respond to market fluctuations and prevent drug shortages.

Despite these benefits and strong regulatory support, adoption by the generic industry has been slow. The primary hurdles are the significant upfront capital investment required to switch from established batch processes and the economic uncertainty of investing in a new technology for low-margin products. However, as the technology matures and the long-term cost benefits become clearer, CM is poised to become a key differentiator for the next generation of generic manufacturers.

Beyond the Minimum: The FDA’s Push for Quality Management Maturity (QMM)

Perhaps the most significant evolution in the regulatory landscape is a philosophical one. For decades, GMP compliance has been viewed as a binary, “pass/fail” system. A facility either met the minimum requirements, or it did not. The FDA is now spearheading a new initiative that seeks to move beyond this model: the Quality Management Maturity (QMM) program.

QMM is defined as the state of having consistent, reliable, and robust business processes to achieve quality objectives and promote continual improvement.100 It is a measure of how well a manufacturer has implemented the principles of ICH Q10 and other modern quality management concepts to create a system that not only meets but

exceeds the minimum standards of cGMP.

The impetus for the QMM program comes directly from the persistent problem of drug shortages, which are often rooted in manufacturing quality issues. The program’s goals are to:

- Foster a strong, proactive quality culture within the industry.

- Recognize and reward manufacturers that have achieved high levels of QMM.

- Provide a framework for all manufacturers to assess and improve their quality systems.

This initiative could fundamentally change the business calculus for generic manufacturers. The FDA is developing a rating system to objectively assess a facility’s QMM. If these ratings are made transparent to the public and, more importantly, to large-scale drug purchasers like hospitals and Group Purchasing Organizations (GPOs), it could disrupt the current market dynamic that is driven almost exclusively by price.

Consider the potential paradigm shift:

- Current State: A hospital’s purchasing department is often incentivized to select the lowest-priced generic that meets the basic GMP compliance threshold. This creates the “race to the bottom” that can lead to fragile supply chains.

- Future State with QMM: That same purchasing department might now have a choice between two generics. One is priced at $0.10 per dose from a manufacturer with a “Standard” QMM rating. The other is priced at $0.12 per dose from a manufacturer with an “Excellent” QMM rating.

- Faced with the high costs and patient care disruptions caused by drug shortages, the purchaser may be willing to pay the 2-cent premium for the product from the more reliable, higher-rated manufacturer.

- This creates a powerful, market-based incentive for manufacturers to invest in quality beyond the minimum. It allows companies with superior quality systems to differentiate themselves and potentially command a modest price premium, making their business model more sustainable.

The QMM program signals a future where GMP compliance is no longer just the finish line, but the starting point. It transforms quality from a regulatory hurdle into a tangible, competitive asset, potentially rebalancing the scales of the “affordability paradox” in favor of a more resilient and reliable generic drug supply chain.

Section 8: Conclusion: GMP as a Strategic Differentiator

The role of Good Manufacturing Practice in the generic drug industry is far more profound than that of a simple regulatory checklist. It is the essential, symbiotic partner to the Abbreviated New Drug Application process, providing the tangible proof of quality that makes the entire generic value proposition possible. Without the rigorous, systematic controls mandated by GMP, the trust that underpins the use of these affordable medicines would evaporate, and the billions of dollars in healthcare savings they generate would vanish.

Throughout this report, we have journeyed from the foundational principles of GMP and its global regulatory frameworks under the FDA and EMA, to its practical application on the manufacturing floor. We have seen how every aspect of production—from the training of personnel and the qualification of equipment to the integrity of a single data point in a batch record—is woven into a comprehensive Pharmaceutical Quality System designed to ensure that every dose of a generic drug is as safe and effective as its brand-name counterpart.

However, the landscape is fraught with challenges. The intense economic pressures of the generic market create a constant tension, where the drive for cost-efficiency can threaten the very investments needed for robust quality. The complexities of global supply chains introduce risks that demand unprecedented levels of oversight and transparency. The consequences of failure are severe, ranging from regulatory citations to product recalls and a devastating loss of market access and public trust.

Yet, it is within these challenges that opportunity lies. The future of generic manufacturing will not belong to those who view GMP as a burden to be minimally met, but to those who embrace it as a framework for achieving true operational excellence. The evolution toward Pharma 4.0, Continuous Manufacturing, and the FDA’s forward-thinking Quality Management Maturity initiative signals a clear trajectory: quality is becoming the ultimate competitive differentiator.

In the years to come, the most successful generic companies will be those that leverage technology to build smarter, more efficient, and more reliable manufacturing processes. They will be the ones who use data not just for compliance, but for prediction and continual improvement. They will cultivate a quality culture that permeates every level of the organization, driven by a leadership that understands that a long-term investment in quality is the most effective strategy for mitigating risk and ensuring sustainable profitability.

Ultimately, GMP is the unseen guardian of patient safety and the silent guarantor of the generic promise. For the strategic leaders of this vital industry, mastering its principles is not just a regulatory necessity; it is a business imperative and an ethical obligation.

Key Takeaways

- GMP is the Foundation of Trust: Good Manufacturing Practice is not just a set of rules; it is the essential system that provides the proof of quality, safety, and consistency, making the streamlined Abbreviated New Drug Application (ANDA) process for generics possible and credible.

- Global Compliance is Complex: Generic manufacturers must navigate and harmonize the detailed requirements of major regulatory bodies like the U.S. FDA (21 CFR Parts 210 & 211) and the European EMA (EudraLex Volume 4), creating a single, robust Pharmaceutical Quality System (PQS) that meets the highest global standard.

- Quality Must Be Systemic: A modern PQS, guided by principles like ICH Q10, transforms GMP from a reactive compliance task into a proactive system for continual improvement, driven by Knowledge Management and Quality Risk Management.

- Data Integrity is Paramount: Meticulous documentation, particularly through Batch Production Records, and adherence to principles for electronic data (21 CFR Part 11) and data trustworthiness (ALCOA+), are critical for withstanding regulatory scrutiny. Data integrity failures are a leading cause of severe enforcement actions.

- Economic Pressures Create Quality Risks: The intense price competition in the generic market creates a significant challenge, potentially disincentivizing investments in quality and supply chain resilience, which is a root cause of drug shortages.

- Non-Compliance Has Severe Consequences: Failures in GMP can lead to a cascade of negative outcomes, from FDA Form 483 observations and Warning Letters to product recalls, import alerts, and significant financial and reputational damage.

- The Future of GMP is Digital and Proactive: The industry is evolving with Pharma 4.0, Continuous Manufacturing, and AI, which offer new ways to enhance quality and efficiency.

- Quality is Becoming a Competitive Differentiator: The FDA’s Quality Management Maturity (QMM) initiative signals a shift from a “pass/fail” compliance model to a tiered system where demonstrable quality excellence can become a tangible market advantage, rewarding reliable manufacturers and helping to secure the drug supply chain.

Frequently Asked Questions (FAQ)

1. How can a small generic startup with limited capital effectively compete on GMP compliance with large, established players?

A startup can compete effectively by being smarter, not just bigger. Instead of investing in massive physical infrastructure, they can leverage modern, cloud-based electronic Quality Management Systems (eQMS) to ensure robust documentation and data integrity from day one. By adopting a rigorous Quality Risk Management (QRM) approach, they can focus their limited resources on the highest-risk areas of their process. Furthermore, by designing a lean, efficient process using Quality by Design (QbD) principles during development, they can build compliance in from the start, avoiding costly retrofitting and remediation later. The key is to make quality a core part of the initial business strategy, not an afterthought.

2. With the rise of continuous manufacturing, will traditional batch records become obsolete, and how does this impact GMP?

Traditional, paper-based batch records as we know them will likely become obsolete in a fully continuous manufacturing (CM) environment, but the principle of the batch record will not. GMP will still require a complete and traceable history of production. In CM, this will evolve into a “continuous batch record” or a comprehensive data log. Instead of a stack of paper, it will be a validated electronic system that captures a continuous stream of process parameter data, material tracking information, and in-line quality measurements. The concept of a “batch” may be defined by time (e.g., 24 hours of production) or quantity. The principles of 21 CFR Part 11 and ALCOA+ become even more critical in this environment to ensure the integrity of the massive volume of data generated.

3. If a generic drug is proven bioequivalent, why do regulators care so much about minor differences in the manufacturing process compared to the brand?

Bioequivalence is typically demonstrated on a few specific batches of the drug. Regulators care intensely about the manufacturing process because it is the only guarantee that every batch produced over the product’s entire lifecycle will also be bioequivalent. A seemingly minor, uncontrolled change in the process—for example, a different mixing speed, a new source of an excipient, or a slight change in compression force—could alter the drug’s physical properties (like its dissolution rate) just enough to affect its absorption in the body. Since it’s not feasible to repeat human bioequivalence studies for every process change, strict adherence to a validated process under GMP is the regulator’s primary tool for ensuring consistent therapeutic performance from batch to batch, year after year.

4. How does the FDA’s Quality Management Maturity (QMM) initiative change the business calculus for a generic manufacturer?

The QMM initiative has the potential to fundamentally change the business model from a pure commodity play to one where quality is a marketable asset. Currently, the primary competitive lever is price. A QMM rating system could introduce a second, powerful lever: demonstrated supply chain reliability. If purchasers like hospitals and insurers begin to factor a manufacturer’s QMM score into their contracting decisions—potentially paying a small premium for a more reliable supplier to avoid the high costs of drug shortages—it changes the entire calculus. It creates a direct financial incentive to invest in quality systems that exceed the minimum cGMP requirements. This could allow high-quality manufacturers to escape the “race to the bottom” on price and build a more sustainable business based on demonstrable excellence and reliability.

5. My company sources APIs from multiple global suppliers. What are the most critical GMP red flags to look for during a supplier audit?

During a supplier audit, beyond checking the basics of facility cleanliness and equipment maintenance, there are several critical red flags to look for:

- Poor Data Integrity Practices: Look for shared passwords for computer systems, missing or incomplete audit trails, the use of “test” injections in chromatography that are not reported, and unofficial paper records. These are strong indicators that the data cannot be trusted.

- Inadequate Change Control: A weak change control system is a major risk. If the supplier cannot demonstrate a robust, documented process for evaluating and validating any changes to their manufacturing process, you have no assurance that the API you receive next year will be the same as the one you qualified today.

- Insufficient Investigation of Deviations: Review their deviation and out-of-specification (OOS) investigation reports. If they are superficial, fail to identify a true root cause, and repeatedly conclude “operator error” without addressing systemic issues, it suggests a reactive and weak quality culture.

- Lack of Traceability: The supplier must be able to trace every batch of API back to the specific lots of raw materials and intermediates used in its production. Any gaps in this traceability are a significant compliance and safety risk.

References

- The Global Generic Drug Market: Trends, Opportunities, and Challenges – DrugPatentWatch, accessed August 4, 2025, https://www.drugpatentwatch.com/blog/the-global-generic-drug-market-trends-opportunities-and-challenges/

- Generic Drugs Market Size, Research, Trends and Forecast – Towards Healthcare, accessed August 4, 2025, https://www.towardshealthcare.com/insights/generic-drugs-market

- The Price of Health: Deconstructing the True Cost of Generic Drug Production, accessed August 4, 2025, https://www.drugpatentwatch.com/blog/breaking-down-the-cost-of-generic-drug-production-understanding-the-factors-influencing-affordability/

- Top 10 Challenges in Generic Drug Development – DrugPatentWatch, accessed August 4, 2025, https://www.drugpatentwatch.com/blog/top-10-challenges-in-generic-drug-development/

- Streamlining the Generic Drug Supply Chain: Best Practices – DrugPatentWatch, accessed August 4, 2025, https://www.drugpatentwatch.com/blog/streamlining-the-generic-drug-supply-chain-best-practices/

- Generic vs. Brand-Name Drugs: What’s the Difference? – Humana, accessed August 4, 2025, https://www.humana.com/pharmacy/medication-information/difference-between-generic-and-brand-drug

- 7 FAQs About Generic Drugs | Pfizer, accessed August 4, 2025, https://www.pfizer.com/news/articles/7_faqs_about_generic_drugs

- How to Ensure Your Generic Drug Meets FDA Standards: A Comprehensive Guide, accessed August 4, 2025, https://www.drugpatentwatch.com/blog/how-to-ensure-your-generic-drug-meets-fda-standards/

- Generic Drugs: Questions & Answers – FDA, accessed August 4, 2025, https://www.fda.gov/drugs/frequently-asked-questions-popular-topics/generic-drugs-questions-answers

- Generic Medicines, accessed August 4, 2025, https://accessiblemeds.org/about/generic-medicines/

- Abbreviated New Drug Application – Wikipedia, accessed August 4, 2025, https://en.wikipedia.org/wiki/Abbreviated_New_Drug_Application

- A primer on generic drugs and bioequivalence – FDA, accessed August 4, 2025, https://www.fda.gov/files/about%20fda/published/Generic-Drugs-and-Bioequivalence—Presentation.pdf

- The Impact of Generic Drugs on Healthcare Costs – DrugPatentWatch, accessed August 4, 2025, https://www.drugpatentwatch.com/blog/the-impact-of-generic-drugs-on-healthcare-costs/

- What is ANDA? – UPM Pharmaceuticals, accessed August 4, 2025, https://www.upm-inc.com/what-is-anda

- The ANDA Process: A Guide to FDA Submission & Approval – Excedr, accessed August 4, 2025, https://www.excedr.com/blog/what-is-abbreviated-new-drug-application

- Abbreviated New Drug Application (ANDA) – FDA, accessed August 4, 2025, https://www.fda.gov/drugs/types-applications/abbreviated-new-drug-application-anda

- Abbreviated New Drug Applications (ANDA) Explained: A Quick-Guide – The FDA Group, accessed August 4, 2025, https://www.thefdagroup.com/blog/abbreviated-new-drug-applications-anda

- www.fda.gov, accessed August 4, 2025, https://www.fda.gov/drugs/pharmaceutical-quality-resources/current-good-manufacturing-practice-cgmp-regulations#:~:text=The%20CGMP%20regulations%20for%20drugs,strength%20it%20claims%20to%20have.

- What is GMP | cGMP | Good Manufacturing Practice | ISPE | International Society for Pharmaceutical Engineering, accessed August 4, 2025, https://ispe.org/initiatives/regulatory-resources/gmp/what-is-gmp