Executive Summary

The Active Pharmaceutical Ingredient (API) manufacturing sector stands at a critical inflection point, driven by the dual pressures of increasing molecular complexity in drug pipelines and mounting demands for greater efficiency, quality, and supply chain resilience. This report provides an exhaustive analysis of the strategic imperatives and technological transformations shaping the future of API production. It moves beyond a siloed examination of individual technologies to present a synthesized view of how foundational quality frameworks, advanced process paradigms, digital technologies, and sustainability mandates are converging to create a new competitive frontier.

The core challenge confronting the industry is a self-reinforcing cycle where the pursuit of more targeted therapeutics leads to more complex APIs. This complexity results in longer, lower-yielding synthetic routes, which in turn amplifies the risks associated with impurities, complicates scale-up, and inflates both economic and environmental costs. Breaking this cycle is the central objective of modern API manufacturing optimization.

Foundational frameworks such as Quality by Design (QbD) and Process Analytical Technology (PAT) are no longer optional quality initiatives but have become the essential “operating system” for advanced manufacturing. They provide the deep process understanding and real-time data streams necessary to implement and validate more sophisticated production systems. Concurrently, the principles of Green Chemistry have evolved from an environmental ideal to a strategic driver of innovation. By imposing constraints on waste, energy, and hazardous materials, these principles act as a forcing function, compelling the development of more efficient and economically superior processes, as powerfully demonstrated by Pfizer’s award-winning redesign of the sertraline manufacturing process.

The most significant paradigm shift is the transition from traditional batch processing to Continuous Manufacturing (CM). CM offers transformative benefits in efficiency, quality consistency, and cost-effectiveness, with analyses showing potential capital expenditure reductions of up to 76% and overall cost savings ranging from 9% to 40%. More strategically, the smaller footprint and modularity of CM facilities make it a key enabler of supply chain resilience, providing an economically viable pathway for reshoring critical API production and mitigating the geopolitical risks exposed during the recent pandemic.

Layered upon this new manufacturing paradigm is the rise of the “smart factory,” powered by Industry 4.0 technologies. Artificial Intelligence (AI) and Machine Learning (ML) are evolving process control from a reactive to a predictive and prescriptive function, optimizing yields and enabling predictive maintenance to eliminate costly downtime. Automation and robotics are enhancing precision and safety, particularly in hazardous or aseptic operations, boosting throughput by up to 50% and reducing defects by as much as 80%. This digital transformation elevates data to the status of a critical raw material and shifts the role of the human operator from manual control to system orchestration, demanding a new generation of skills in data science and automation engineering.

Finally, upstream innovations in synthesis design and catalysis offer the most profound leverage for optimization. AI-powered Computer-Aided Retrosynthesis (CAR) is accelerating the design of novel, more efficient synthetic pathways, while advancements in biocatalysis, organocatalysis, and flow chemistry are revolutionizing the core chemistry itself, often eliminating multiple process steps and their associated costs and waste.

This report concludes with a strategic blueprint for industry stakeholders. The future of API manufacturing will be defined by the ability to produce personalized medicines on-demand, a reality made possible by the convergence of these trends. Success will depend not on adopting a single technology, but on holistically integrating these elements into a cohesive strategy. The recommendations are clear: embed QbD as a corporate culture, invest strategically in modular CM platforms, build a robust digital infrastructure, champion green chemistry as a profit center, and foster a future-ready workforce. The companies that master this new, integrated paradigm will not only achieve operational excellence but will also define the next era of pharmaceutical innovation and patient care.

Section 1: The Modern API Manufacturing Landscape

The foundation of any therapeutic product is its Active Pharmaceutical Ingredient (API). The process of manufacturing this critical component is a highly specialized, multi-stage endeavor that lies at the intersection of advanced chemistry, precision engineering, and stringent regulatory oversight. Understanding the intricacies of this landscape—from the definition and categorization of APIs to the complex challenges inherent in their production—is essential for contextualizing the modern drive toward optimization. The goal of API manufacturing is to produce these biologically active substances in a manner that is not only competitively priced but also meets exacting quality standards with the least possible environmental impact.1

1.1 Defining the Active Pharmaceutical Ingredient (API)

At its core, an API is any substance or mixture of substances intended to furnish pharmacological activity or other direct effect in the diagnosis, cure, mitigation, treatment, or prevention of disease.2 It is the component of the final drug product that serves as the active, therapeutic agent.1 The global API market is vast and growing, with cardiovascular drugs, central nervous system disorder treatments, and oncology therapies representing major therapeutic segments.1 APIs are broadly categorized based on their molecular structure and production method, a distinction that fundamentally shapes their manufacturing processes.

Categorization of APIs

- Small Molecules: These are chemically synthesized compounds with a low molecular weight. They represent the majority of drugs on the market and are typically produced through multi-step organic chemical synthesis.3 Their production involves a series of precisely controlled chemical reactions designed to build the complex target molecule from simpler starting materials.

- Biologics: This category includes large, complex molecules such as proteins, peptides, and nucleic acids. Unlike small molecules, biologics are produced through biotechnological processes in living systems, such as fermentation using microorganisms or culture of mammalian cells.7 The market for biologics is expanding rapidly, driven in large part by the development of innovative oncology treatments and other highly potent APIs (HPAPIs) that require specialized handling and manufacturing facilities.1

- Advanced Therapy Medicinal Products (ATMPs): ATMPs represent a cutting-edge class of medicines that includes gene therapies, somatic cell therapies, and tissue-engineered products.10 These products are governed by a distinct and continuously evolving regulatory framework, reflecting their complexity and novel therapeutic mechanisms.11 Their manufacturing processes are highly specialized and present unique challenges in quality control, scalability, and logistics.

1.2 The Core Manufacturing Lifecycle

The journey from raw starting materials to a finished, high-purity API is a sequential process involving several critical unit operations. While the specifics vary depending on the API’s category, the general lifecycle encompasses synthesis, purification, and finishing steps.5

Process Overview

The manufacturing process is a series of related operations that may include multi-step chemical synthesis, fermentation, purification, drying, milling, and labeling.13 Each step must be performed under strictly controlled conditions to ensure the final product meets its predefined quality specifications for strength, purity, and safety.14

Synthesis Stage

The synthesis stage is where the API molecule is first created. The method employed is determined by the nature of the API:

- Chemical Synthesis: This is the predominant method for small molecules. It involves a carefully designed sequence of chemical reactions that transform raw materials (or starting materials) into intermediates, which then undergo further reactions to yield the final API.5

- Fermentation: This biological process is used for many biologics, such as antibiotics. It involves cultivating microorganisms (e.g., bacteria, fungi) in a controlled environment, where they metabolize specific nutrients to produce the desired API.4

- Extraction: Some APIs are derived from natural sources, such as plants or animals. The active compound is isolated from the natural material through an extraction process.4

Downstream Processing (Purification and Finishing)

Following synthesis, the crude API is a mixture containing the desired product along with various impurities, including unreacted starting materials, by-products, and residual solvents. The downstream processing stage is dedicated to removing these impurities to achieve the required level of purity.7 Key operations include:

- Filtration and Separation: Used to separate solids from liquids and remove particulate matter.7

- Crystallization: A critical purification technique where the API is dissolved in a suitable solvent and then precipitated out as pure crystals, leaving impurities behind in the mother liquor.5

- Chromatography: A powerful separation technique used to isolate the API from impurities with very similar chemical properties.7

- Drying and Milling: The purified, crystallized API is dried to remove any remaining solvents and then milled to achieve a specific particle size and distribution, which is critical for the formulation of the final drug product.5 At industrial scale, these final steps of filtration and drying frequently become the primary bottlenecks in the production line, limiting overall throughput.17

1.3 The Challenge Matrix: Navigating Complexity, Purity, and Cost

The imperative to optimize API manufacturing is driven by a matrix of interconnected and often competing challenges. Modern drug development trends, stringent quality requirements, and intense economic pressures create a complex operational environment that demands continuous innovation.

Increasing Molecular Complexity

The frontier of medicine, particularly in areas like oncology, is pushing toward therapies that are highly targeted to specific biological pathways. This requires the design of API molecules with increasingly sophisticated and complex structures.18 These molecules often feature multiple chiral centers (requiring precise three-dimensional control), difficult-to-handle functional groups, and quaternary carbon centers, all of which are inherently challenging to synthesize.19 This structural complexity has a direct and significant consequence: it necessitates longer and more intricate synthetic routes. A process that may have taken three or four steps for an older drug might now require eight or more steps for a modern API. This increase in the number of steps directly escalates the complexity of the overall manufacturing process and often leads to dramatically lower overall yields. For instance, a client project for a Phase 1 API with an eight-step synthesis reported an initial overall yield of just 14%, creating a significant challenge for meeting production timelines.19

The Imperative of Purity and Impurity Control

In pharmaceutical manufacturing, purity is non-negotiable. Even minute quantities of impurities can have profound effects on a drug’s safety, efficacy, or stability, potentially leading to adverse patient outcomes, product recalls, and severe regulatory action.20 Regulatory bodies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) enforce strict limits on impurities, making their control a central focus of API development.21

Impurities can be introduced at virtually any stage of the manufacturing lifecycle. Sources include contaminants present in raw materials, reagents, and solvents; by-products generated from side reactions during synthesis; unreacted intermediates; and degradation products that form during processing or storage.21 The quality of the inputs has a direct, cascading effect on the quality of the output. The use of low-purity raw materials or reagents can introduce unwanted substances that may be difficult to remove later, catalyze side reactions that lower the yield of the desired product, and generate new impurities that complicate the purification process.24 This reality necessitates the practice of rigorous impurity profiling—the systematic identification, structural elucidation, and quantification of every impurity present in the API—as a cornerstone of process development and quality control.21

The Triad of Yield, Cost, and Scale-Up

The economic viability of a drug is heavily influenced by the cost of its API, which is often the most expensive component of the final product.14 The low overall yields resulting from complex, multi-step syntheses directly inflate the cost of goods sold (COGS), as more raw material and resources are consumed for every kilogram of final product produced.19

Perhaps the most formidable technical challenge in API manufacturing is the transition from laboratory-scale synthesis to industrial-scale production. A chemical reaction that is well-behaved in a one-liter glass flask can become unpredictable and dangerous in a ten-thousand-liter steel reactor. Inefficiencies in heat and mass transfer at large scales can lead to the formation of temperature gradients and localized “hotspots,” which can cause incomplete reactions, generate new impurities, or even trigger runaway reactions with serious safety implications.20 What appears as a negligible trace impurity at the lab bench can accumulate to problematic and unacceptable levels when the process is scaled up by several orders of magnitude.20 Successfully navigating this scale-up challenge requires deep engineering expertise and meticulous process development.

Environmental and Sustainability Pressures

API manufacturing is a resource-intensive industry with a significant environmental footprint. The sheer volume of materials used—including raw materials, solvents, reagents, and water—is often vastly greater than the amount of final product produced. This is quantified by the Process Mass Intensity (PMI), a key green chemistry metric that measures the ratio of the total mass of inputs to the mass of the final API. In the pharmaceutical industry, PMIs can frequently exceed 100, meaning over 100 kilograms of material are used to produce just one kilogram of API.29 This high material throughput results in the generation of substantial liquid and solid waste and contributes to a large carbon footprint, with API emission factors ranging from 50 to 1,000 kg of

CO2 per kg of API, largely due to heavy solvent use and subsequent incineration.30

These interconnected challenges create a difficult operating environment. The market’s demand for more effective, targeted therapies drives an increase in molecular complexity. This complexity, in turn, leads to longer synthetic routes with lower yields, which amplifies the impact of raw material impurities and makes the purification process more challenging and costly. This entire cycle not only increases the final cost of the drug but also exacerbates the environmental impact of its production. This dynamic establishes a powerful incentive for the industry to seek out and adopt the innovative optimization strategies that form the core of this report. The traditional approach of optimizing for a single variable, such as cost-per-kilo, is no longer sufficient. The modern view of manufacturing excellence has expanded to encompass a more holistic definition of cost, one that internalizes the “total cost of quality.” This broader perspective recognizes that the initial price of a raw material is only a small part of its true economic impact. A cheaper, lower-purity reagent may seem attractive, but if it leads to lower yields, more complex purification, increased solvent and energy consumption for rework, and a higher risk of a batch failing to meet stringent regulatory specifications, its true cost is far higher. A single failed batch can represent a total loss of all input costs and, more critically, can lead to drug shortages that carry immense financial and reputational penalties. This sophisticated understanding of cost justifies the significant upfront investments in the advanced technologies and quality frameworks that are redefining API manufacturing.

Section 2: Foundational Pillars of Quality and Efficiency

In response to the complex challenges of modern API manufacturing, the industry has moved away from a reactive, test-and-release approach to quality. Instead, it has embraced a set of proactive, science-driven frameworks designed to build quality, efficiency, and sustainability into processes from their inception. Quality by Design (QbD), Process Analytical Technology (PAT), and the principles of Green Chemistry are not merely regulatory hurdles or corporate social responsibility initiatives; they are foundational pillars that enable robust, reliable, and economically competitive manufacturing. These frameworks form an integrated system that provides the deep process understanding required to navigate complexity and drive continuous improvement.

2.1 Quality by Design (QbD): A Proactive Framework for Excellence

Quality by Design (QbD) represents a fundamental shift in the philosophy of pharmaceutical development. It is a systematic, scientific, and risk-based approach that begins with predefined objectives and emphasizes deep product and process understanding and control.31 The core tenet of QbD is that quality cannot be tested into a product at the end of the line; it must be designed and built into the manufacturing process from the very beginning.32 This proactive methodology is a foundational concept for ensuring product consistency, enhancing process robustness, and facilitating a lifecycle of continuous improvement.33

Key Elements of QbD

The implementation of QbD is structured around several key elements, guided by the International Council for Harmonisation (ICH) guidelines Q8, Q9, and Q10 31:

- Quality Target Product Profile (QTPP): The process begins with the end in mind. The QTPP is a prospective summary of the quality characteristics of a drug product that ideally will be achieved to ensure the desired quality, taking into account safety and efficacy.31 It translates the needs of the patient into tangible, measurable objectives for the development team.

- Critical Quality Attributes (CQAs): Based on the QTPP, the team identifies the CQAs of the API. These are the physical, chemical, biological, or microbiological properties that must be controlled within a specific limit, range, or distribution to ensure the desired product quality.31 For an API, common CQAs include purity, the levels of specific impurities, polymorphic form, particle size distribution, and water content.35

- Critical Process Parameters (CPPs): These are the variables within the manufacturing process whose variability has a direct and significant impact on a CQA and therefore should be monitored or controlled to ensure the process produces the desired quality.31 Examples include reaction temperature, pressure, reagent addition rates, and mixing speed.

Implementation

The QbD methodology uses these elements in a structured workflow. It starts by defining the QTPP and identifying the CQAs of the API. Then, through a process of risk assessment (as outlined in ICH Q9), potential CPPs and critical material attributes (CMAs) of raw materials are identified and prioritized based on their potential impact on the CQAs.31 Statistical tools, most notably Design of Experiments (DoE), are then employed to systematically study the relationships between these critical parameters and the quality attributes.32 This scientific investigation establishes a “Design Space”—a multidimensional combination and interaction of input variables and process parameters that has been demonstrated to provide assurance of quality.31 Operating within this validated Design Space provides operational flexibility and is a key outcome of the QbD approach. The entire process culminates in the development of a comprehensive Control Strategy, which is a planned set of controls, derived from product and process understanding, that ensures process performance and product quality.31

2.2 Process Analytical Technology (PAT): The Engine of Real-Time Understanding

If QbD provides the strategic map for achieving quality, Process Analytical Technology (PAT) provides the real-time navigation system. PAT is defined as a system for designing, analyzing, and controlling manufacturing through timely measurements of critical quality and performance attributes of raw and in-process materials and processes.38 It is the primary enabler of QbD, providing the continuous stream of data required to truly understand, monitor, and control a process within its Design Space.34

PAT Tools and Applications

The practical implementation of PAT involves integrating various analytical instruments directly into the manufacturing line. These tools can operate in-line (directly in the process stream), on-line (diverting a sample for analysis and returning it), or at-line (taking a sample to an instrument located next to the process line for quick analysis). Common PAT tools include spectroscopic methods (like near-infrared and Raman spectroscopy) and chromatographic techniques, which can provide real-time information on chemical composition, concentration, particle size, and other critical attributes.39 These technologies allow for the continuous monitoring of key unit operations such as chemical reactions, crystallizations, and drying.39

Benefits

By providing a window into the process as it happens, PAT facilitates a level of process understanding that is impossible to achieve with traditional offline testing. This deep understanding allows for the development of more robust processes, reduces cycle times by eliminating waiting periods for lab results, minimizes product rework and scrap, and enhances safety.39 Ultimately, a well-implemented PAT system can support Real-Time Release Testing (RTRT), a state where the decision to release a product is based on the in-process data collected during manufacturing, rather than on end-product testing alone.41 This represents a significant leap in both efficiency and quality assurance.

2.3 The Green Chemistry Mandate: Aligning Sustainability with Profitability

Running parallel to the quality-focused initiatives of QbD and PAT is the growing mandate for environmental sustainability, embodied by the principles of Green Chemistry. Green Chemistry is a design framework aimed at reducing or eliminating the use and generation of hazardous substances throughout the lifecycle of a chemical product.45 What began as an environmental movement has evolved into a powerful business strategy, as the principles of sustainability are often perfectly aligned with the goals of economic efficiency and process robustness.

The 12 Principles as a Business Strategy

The 12 Principles of Green Chemistry provide a blueprint for more efficient and less wasteful chemical manufacturing. Core tenets include preventing waste at the source (the most important principle), maximizing “atom economy” (ensuring most atoms from the reactants end up in the final product), using safer solvents and reagents, designing for energy efficiency, and favoring catalytic reactions over stoichiometric ones.29 Adopting these principles directly translates into significant business advantages. It reduces the high costs associated with hazardous waste disposal, lowers energy consumption, improves worker safety by minimizing exposure to toxic substances, and often leads to higher process yields and fewer purification steps.49 Metrics such as the E-Factor (kg of waste per kg of product) and Process Mass Intensity (PMI) are used to quantify the environmental impact and material efficiency of a process, providing a tangible way to measure and benchmark progress.29

Case Study in Focus: Pfizer’s Award-Winning Redesign of the Sertraline (Zoloft®) Process

The transformative power of applying Green Chemistry principles is vividly illustrated by Pfizer’s redesign of the manufacturing process for sertraline, the API in the antidepressant Zoloft®. This achievement earned the company a prestigious U.S. Presidential Green Chemistry Challenge Award in 2002.52

- The Challenge: The original commercial process for sertraline involved a three-step sequence that was inefficient and generated significant waste. It required the use of four different and hazardous solvents (methylene chloride, tetrahydrofuran, toluene, and hexane) and a problematic reagent, titanium tetrachloride, which produced large quantities of solid and liquid waste.52

- The Solution: Pfizer’s chemical development team meticulously re-engineered the process, consolidating the three-step sequence into a single, highly efficient “combined” step. A critical innovation was the switch to ethanol, a single, far more benign solvent, for the entire sequence. This change alone eliminated the need to use, distill, and recover the four previous solvents. Furthermore, by cleverly using solubility differences to drive the reaction, they eliminated the need for titanium tetrachloride entirely.52

- The Outcome: The results were dramatic. The new, greener process doubled the overall product yield. It eliminated the use or generation of approximately 1.8 million pounds of hazardous materials annually, including 970,000 pounds of solid titanium dioxide waste. Raw material use was cut by 20–60%, and both energy and water consumption were reduced. The new process was not only substantially better for the environment but also safer for workers and more cost-effective for the company.52

This case study powerfully demonstrates that sustainability and profitability are not mutually exclusive. The constraints imposed by Green Chemistry principles often act as a powerful forcing function for innovation. The mandate to avoid a hazardous reagent or a toxic solvent compels chemists and engineers to discover novel and more elegant solutions. In the case of sertraline, the quest for a “green” process led directly to a process that was also more efficient, higher-yielding, and more economical. This reveals a deeper truth about modern manufacturing: the most sustainable process is frequently the most advanced and profitable one.

These foundational pillars—QbD, PAT, and Green Chemistry—are not independent initiatives. They form a synergistic system. QbD provides the strategic framework for understanding what needs to be controlled to ensure quality. PAT provides the tactical tools to monitor and control the process in real time. Green Chemistry provides the design principles to ensure the underlying chemistry is as efficient and sustainable as possible. Together, they create the necessary foundation—the “operating system”—upon which the more advanced manufacturing technologies of Industry 4.0 can be successfully built and validated. Without the deep process understanding generated through this integrated approach, attempts to implement complex systems like continuous manufacturing or AI-driven process control would be fundamentally unworkable and impossible to validate for regulatory approval.

Section 3: The Continuous Manufacturing Revolution

The most significant operational and technological shift in modern API production is the move away from traditional batch manufacturing toward a fully integrated, continuous process. This transition represents more than an incremental improvement; it is a fundamental paradigm shift that redefines the relationship between process design, quality assurance, and supply chain strategy. Continuous Manufacturing (CM) offers a transformative approach to addressing the core challenges of cost, quality, and efficiency that have long constrained the pharmaceutical industry.

3.1 Paradigm Shift: From Batch to Continuous Processing

To appreciate the magnitude of this shift, it is essential to understand the fundamental differences between the two manufacturing modalities.

Defining the Modalities

- Batch Manufacturing: This is the long-established industry standard. It operates like a series of distinct culinary steps: a finite quantity of materials (a “batch”) is loaded into a vessel, processed through a single unit operation (e.g., reaction, crystallization), and then discharged. The entire batch is then held, tested, and manually transferred to the next piece of equipment for the subsequent operation.55 This process is characterized by its sequential, start-and-stop nature, with significant downtime and intermediate material handling between steps.

- Continuous Manufacturing (CM): In stark contrast, CM is an integrated, uninterrupted process. Raw materials are continuously fed into one end of a closed system, flow through a series of connected unit operations, and emerge as the final product at the other end without interruption.57 The system operates in a steady state, eliminating the discrete steps, hold times, and manual interventions inherent to batch processing.

Comparative Analysis

The strategic advantages of CM become clear when compared directly with batch processing across several key performance indicators. The following table synthesizes data from numerous industry analyses to provide a clear, at-a-glance comparison.

| Parameter | Batch Manufacturing | Continuous Manufacturing (CM) | Supporting Sources |

| Scalability | Limited by equipment size; scaling up requires larger vessels and process re-validation. | Superior; production volume is a function of run time, not equipment size. Scale-out is simpler. | 55 |

| Flexibility | Traditionally more flexible for multi-product facilities and frequent changeovers. | Historically less flexible, but modern modular designs are significantly improving adaptability. | 60 |

| Capital Expenditure (CapEx) | High, due to large equipment, extensive facility footprint, and multiple separate processing suites. | 20% to 76% lower due to smaller, intensified equipment and a significantly reduced facility footprint. | 62 |

| Operating Expenditure (OpEx) | Higher, due to increased labor, manual handling, energy for start/stop cycles, and larger inventories. | 9% to 40% lower overall cost savings, driven by automation, energy efficiency, and higher yields. | 55 |

| Product Quality & Consistency | Prone to batch-to-batch variability; quality is often assured by extensive end-product testing. | Superior consistency due to steady-state operation and real-time monitoring (PAT), minimizing variability. | 59 |

| Manufacturing Footprint | Large, often requiring entire facilities with multiple floors and cleanroom classifications. | Up to 10 times smaller; a process can be housed in a single room or a modular skid. | 62 |

| Production Cycle Time | Long, often spanning several weeks or months due to sequential steps and hold times. | Dramatically shorter, reducing production from weeks to days. | 55 |

| Waste Generation / Sustainability | Higher waste generation (high PMI) and energy consumption due to inefficiencies and start/stop cycles. | Inherently more sustainable with lower energy use, reduced solvent consumption, and less material waste. | 57 |

| Regulatory Pathway | Well-established but rigid; post-approval changes often require significant regulatory filings. | Actively encouraged by FDA/EMA; offers potential for faster approvals and greater operational flexibility post-approval. | 69 |

The adoption of CM is not merely a tactical decision to replace one piece of equipment with another. It compels a holistic re-evaluation of the entire manufacturing process, from the fundamental chemistry to the final quality control strategy. The integrated, uninterrupted nature of a continuous line means that any instability or inefficiency in a single step can jeopardize the entire process. Unlike in batch manufacturing, where a problematic lot can be isolated, reworked, or discarded, a failure in a CM line can bring the entire production to a halt.57 This inherent intolerance for variability forces development teams to design more robust and predictable chemical reactions from the outset, perfectly aligning with the principles of QbD.33 To manage the process dynamics of an integrated system, manufacturers must implement PAT tools for real-time monitoring and control.59 The continuous stream of data generated by these tools, in turn, allows for the creation of sophisticated process models that can predict and optimize performance.68 Thus, the initial goal of improving efficiency through CM acts as a powerful catalyst for a complete overhaul of manufacturing science, resulting in a process that is not just faster, but fundamentally better understood, more tightly controlled, and of a consistently higher quality.

3.2 Enabling Technologies and Process Intensification

The CM revolution is made possible by a suite of enabling technologies that fall under the umbrella of Process Intensification (PI). PI is a chemical engineering discipline focused on developing manufacturing processes that are substantially smaller, cleaner, safer, and more energy-efficient.72 CM is the ultimate expression of PI.

Key Technologies

- Flow Chemistry & Microreactors: At the heart of many CM systems is the shift from large, stirred-tank batch reactors to continuous flow reactors, such as microreactors or plug flow reactors.47 These systems use small-diameter tubes or channels. Their high surface-area-to-volume ratio allows for vastly superior heat and mass transfer compared to large tanks. This enables precise control over reaction conditions, which leads to higher yields, fewer by-products, and dramatically improved safety, especially when handling highly exothermic or hazardous reactions.51

- Modularization: Instead of building large, fixed-in-place manufacturing plants, the industry is moving toward modular designs. A CM process can be built on a series of transportable skids or modules, each containing a specific unit operation. These “plug-and-play” modules can be rapidly assembled, validated, and reconfigured to produce different APIs, offering unprecedented flexibility and reducing the time and cost of building or adapting manufacturing capacity.62

- Advanced Process Control (APC): CM systems are heavily reliant on sophisticated APC strategies. These systems go beyond simple feedback loops, using real-time data from PAT sensors and predictive process models to dynamically adjust CPPs, ensuring the process remains in a state of control and consistently produces a product that meets all CQAs.5

3.3 The Regulatory Horizon: FDA and EMA Perspectives

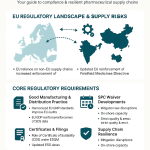

The transition to CM has been strongly supported and encouraged by major global regulatory agencies. Recognizing the potential of CM to enhance product quality, mitigate drug shortages, and strengthen the pharmaceutical supply chain, both the FDA and the EMA have created a favorable regulatory environment for its adoption.57

Key Guidance and Support

The landmark regulatory document is the ICH Q13 guideline, “Continuous Manufacturing of Drug Substances and Drug Products,” which provides a globally harmonized framework for the scientific and regulatory considerations of CM.69 This guidance addresses key topics unique to CM, such as managing process dynamics, developing a suitable control strategy, defining a “batch” (which is often based on run time or quantity of material processed rather than a discrete lot), and establishing procedures for handling process disturbances.69 To further facilitate adoption, the FDA established the Emerging Technology Program (ETP), which allows manufacturers to engage with the agency early in the development process to discuss novel technologies like CM, thereby reducing regulatory uncertainty and smoothing the path to approval.57 Evidence suggests this supportive stance is having a real-world impact, with some analyses indicating that applications involving CM have received regulatory approval significantly faster than their traditional batch counterparts.71

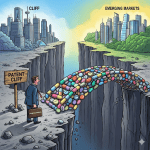

The implications of this paradigm shift extend far beyond the factory floor. The unique characteristics of CM—its smaller footprint, modularity, lower capital and operational costs, and reduced reliance on manual labor—fundamentally alter the strategic calculus of pharmaceutical supply chains. For decades, the high cost of building and operating large-scale batch facilities in Western countries drove the offshoring of API manufacturing to regions with lower labor and construction costs.79 This led to the highly concentrated and vulnerable global supply chains that were severely disrupted during the COVID-19 pandemic.71 CM technology makes it economically feasible to build and operate smaller, more agile, and highly automated API facilities in high-cost regions like the United States and Europe. This shifts the basis of competition from low-cost labor to technological sophistication and process know-how. Consequently, CM is not just a manufacturing technology; it is a powerful strategic tool that enables the reshoring of critical medicine production, enhances national health security, and builds the resilient, diversified supply chains that are now a global imperative.56

Section 4: The Rise of the Smart Factory: Industry 4.0 in API Production

Building on the foundational frameworks of QbD and the paradigm shift to Continuous Manufacturing, the next evolution in API optimization is the integration of Industry 4.0 technologies. This transformation converts traditional manufacturing facilities into “smart factories”—interconnected, data-driven, and intelligent ecosystems. Artificial Intelligence (AI), Machine Learning (ML), automation, and robotics are no longer futuristic concepts but are being actively deployed to drive unprecedented levels of precision, efficiency, and autonomous control in API production.

4.1 Artificial Intelligence and Machine Learning: From Predictive to Prescriptive Control

AI and its subset, ML, are at the core of the smart factory, serving as the “brain” that analyzes the vast streams of data generated by modern processes to unlock actionable insights and drive intelligent decision-making.3

Key Applications

- Process Optimization and Control: The most impactful application of AI/ML is in the real-time optimization of the manufacturing process itself. By training ML models on historical and real-time data from PAT sensors, it is possible to build dynamic models that can accurately predict critical quality attributes like reaction yield or impurity formation based on current process parameters.3 This capability moves process control beyond simple monitoring and feedback loops. It enables

predictive control, where the system can anticipate a deviation before it occurs and make proactive adjustments. The ultimate goal is prescriptive control, where the AI not only predicts an outcome but also recommends or autonomously implements the optimal set of adjustments to CPPs to maintain the process in its most efficient and highest-quality state.85 - Predictive Maintenance: Unplanned equipment downtime is a major source of inefficiency and cost in manufacturing. Predictive maintenance uses ML algorithms to analyze data from equipment sensors—monitoring variables like vibration, temperature, and electrical current—to detect subtle patterns that precede a failure.83 This allows maintenance to be scheduled proactively, preventing catastrophic failures, minimizing costly downtime, and maximizing the operational lifespan of critical equipment.83

- Accelerated Research & Development: The power of AI extends upstream into the drug discovery and development process. AI-driven platforms can rapidly screen vast virtual libraries of chemical compounds to identify promising drug candidates, predict their molecular properties, and even propose novel and optimal synthetic routes.87 This drastically reduces the time and expense of the traditionally slow, trial-and-error approach to R&D. A compelling example is Insilico Medicine’s use of Generative AI, which enabled the company to advance a drug candidate from novel target discovery to a preclinical stage in just 18 months at a fraction of the traditional cost.71

Regulatory Perspective

The integration of AI into a GMP-regulated environment introduces new challenges and considerations for regulatory bodies. The FDA is actively developing a comprehensive framework for AI in drug manufacturing, acknowledging its immense potential while underscoring the critical importance of model validation, data integrity, and transparency.78 A key concern is the “black-box” nature of some complex algorithms. Regulators expect manufacturers to be able to justify the logic behind AI-driven decisions, which has spurred the development of Explainable AI (XAI) techniques that provide insight into how a model arrives at its predictions.78 Ensuring the reliability and auditability of these systems is paramount for their acceptance in GMP-critical applications.90

4.2 Automation and Robotics: Enhancing Precision, Safety, and Throughput

While AI provides the intelligence, automation and robotics provide the physical execution, translating digital commands into precise and reliable actions on the factory floor.

The Roles of Automation and Robotics

- Automation: This broadly refers to the use of control systems and software to operate production processes with minimal human intervention. It ensures that tasks are performed consistently and according to predefined parameters, reducing the potential for human error and improving overall process efficiency.91

- Robotics: This involves the use of physical robots to perform tasks that are highly repetitive, hazardous for humans, or require a level of precision that is difficult to achieve manually.91

Key Applications

- Material Handling and Dispensing: In API manufacturing, the precise weighing and dispensing of raw materials, particularly highly potent compounds, is critical. Robots can perform these tasks with exceptional accuracy and repeatability, ensuring batch consistency, minimizing waste of expensive materials, and protecting human operators from exposure to hazardous substances.91

- Aseptic Processing: In the manufacturing of sterile drug products, minimizing human presence is the most effective way to reduce the risk of microbial contamination. Robotic systems are increasingly being deployed in aseptic filling lines and other cleanroom environments to perform tasks without direct human intervention, significantly enhancing the sterility assurance of the final product.94

- Quality Control Laboratories: QC labs are often a bottleneck in the production cycle due to the high volume of repetitive testing required. Automation and robotics are transforming these labs by performing tasks like sample preparation, liquid handling, and loading analytical instruments. This not only increases sample throughput but also improves data integrity by reducing the chance of manual errors.91

Benefits and Challenges

The strategic deployment of automation and robotics delivers substantial, quantifiable benefits. Industry reports indicate potential increases in production throughput of 30-50%, reductions in product defects by up to 80%, and significant improvements in workplace safety.93 Over the long term, these efficiencies lead to operational cost reductions of up to 40%.91 However, the implementation of these technologies is not without its challenges. The primary hurdles include the high initial capital investment required, the critical need for comprehensive workforce retraining and skill development to manage and maintain these advanced systems, and the emerging risks associated with cybersecurity in a highly connected manufacturing environment.93

Case Study in Focus: GSK’s Smart Manufacturing Hub at Upper Merion

GlaxoSmithKline’s (GSK) manufacturing site in Upper Merion, Pennsylvania, serves as a real-world example of a smart factory in action. Following a $120 million investment, the site was transformed into a technologically advanced hub that leverages a suite of Industry 4.0 technologies.96

- Implementation: The site employs a digitalized scheduling system powered by a real-time modeling engine to optimize the flow of operations. Advanced analytics, including a “digital twin” of the manufacturing process, are used to monitor production in real time and detect early signs of potential faults. Data from across the site is fed into a central digital control room, providing a holistic, end-to-end view of all operations. In the QC labs, robots have been implemented to automate the preparation of samples for testing.96

- Outcomes: The impact has been significant. The digital scheduling system alone was able to unlock an additional 10% of plant capacity by eliminating bottlenecks and improving efficiency. The digital twin allows operators to intervene proactively, preventing deviations before they impact product quality. The use of robotics in the lab has reduced ergonomic strain on employees and minimized investigations caused by human error. This integrated system has demonstrably improved yields, reduced deviations, and accelerated the delivery of medicines to patients.96

The rise of the smart factory signifies a profound shift in the very nature of manufacturing. The effectiveness of AI models and automated systems is entirely contingent on the continuous flow of high-quality, real-time data. This elevates the importance of the underlying data infrastructure—the network of Industrial Internet of Things (IIoT) sensors, integrated data management systems (like MES and LIMS), and PAT tools—to that of a critical raw material.71 A manufacturer’s competitive edge will increasingly be defined not just by its chemical processes, but by its capacity to generate, manage, and transform data into predictive and prescriptive intelligence.

This transformation also redefines the role of the human workforce. As routine manual tasks are automated, the focus shifts from direct process control (“turning the valve”) to higher-level system oversight (“managing the algorithm”). This creates a demand for a new set of skills, moving away from traditional operator roles and toward expertise in data science, automation engineering, control systems, and systems-level thinking.93 The successful transition to a smart factory is therefore as much a challenge of organizational change and human capital development as it is a technological one.

Section 5: Innovations in Synthesis and Catalysis

While advanced manufacturing platforms and digital technologies optimize how a process is executed, innovations in chemical synthesis and catalysis focus on optimizing the core chemistry itself. These upstream advancements are often the most powerful levers for achieving step-change improvements in efficiency, quality, and sustainability. By designing fundamentally better, shorter, and more selective synthetic routes, manufacturers can eliminate entire unit operations and their associated costs, waste, and complexity at the source.

5.1 Designing Novel Pathways: The Role of Computer-Aided Retrosynthesis (CAR)

The design of a synthetic route for a complex API is a highly creative and challenging endeavor. The goal is to devise a sequence of chemical reactions that efficiently transforms simple, commercially available starting materials into the final target molecule, maximizing yield and minimizing steps.98 Traditionally, this process has relied heavily on the experience and intuition of expert chemists and can involve significant time and experimental trial-and-error.99

CAR as a Solution

Computer-Aided Retrosynthesis (CAR) is an AI-powered technology that is revolutionizing this process. CAR software, such as the SYNTHIA® platform, uses sophisticated algorithms and a vast database of expert-coded chemical rules to perform retrosynthetic analysis computationally.99 The user inputs the target API molecule, and the software works backward, deconstructing the molecule into simpler precursors to propose multiple, often novel, synthetic pathways. This allows chemists to quickly and efficiently scan hundreds of potential routes, filtering them based on criteria like cost-effectiveness, step count, and the availability of starting materials, thereby saving immense amounts of time and R&D resources.100

Multi-Target Retrosynthesis

A particularly powerful application of this technology is multi-target retrosynthesis. Instead of analyzing one API at a time, CAR tools can be used to analyze an entire portfolio of target molecules simultaneously. The goal is to identify shared chemical intermediates and common reaction steps that can be used across the synthesis of multiple different APIs.99 This strategy is transformative for manufacturing efficiency, as it enables the design of modular, multi-product manufacturing platforms that can produce a variety of drugs using a common set of core chemical transformations, significantly improving the utilization and return on capital assets.

Case Example: Hantzsch Thiazole Synthesis

A recent study powerfully demonstrated the potential of integrating CAR with advanced manufacturing technology. Researchers used a multi-target CAR approach to analyze 11 different APIs and successfully identified the Hantzsch thiazole synthesis as a central, shared reaction pathway that could be applied to all of them.99 This shared chemical step was then optimized for production using continuous flow chemistry. The results were remarkable: the continuous flow process achieved an isolated yield of 95%, a significant increase from the 84% yield obtained in a traditional batch process. Furthermore, the reaction could be run at a much lower temperature (50 °C vs. 110 °C), and the overall environmental footprint of the process, as measured by the GreenMotion metric, was improved by 25%. This case study exemplifies a powerful synergy: a digital tool (CAR) was used to design a more efficient physical process (a shared synthesis route), which was then enabled and further optimized by an advanced physical technology (continuous flow chemistry).99

5.2 The Power of the Catalyst: Revolutionizing Reaction Efficiency

Catalysis is the cornerstone of modern, efficient chemical synthesis. A catalyst is a substance that increases the rate of a chemical reaction without being consumed itself, enabling transformations that would otherwise be too slow, require excessively harsh conditions, or be completely unfeasible.98 It is estimated that approximately 90% of all commercially produced chemical products, including APIs, involve catalytic processes at some stage.102 Advancements in catalysis are therefore central to the quest for more efficient and sustainable API manufacturing.

Advancements in Catalytic Methods

The field of catalysis is constantly evolving, with several key areas driving innovation in API synthesis:

- Asymmetric Catalysis: Many modern drugs are chiral molecules, meaning they exist as a pair of non-superimposable mirror images (enantiomers). Often, only one of these enantiomers has the desired therapeutic effect, while the other may be inactive or even harmful. Asymmetric catalysis employs chiral catalysts to selectively produce the desired enantiomer, a critical capability for ensuring the safety and efficacy of these drugs.103

- Biocatalysis: This is a key pillar of Green Chemistry. It involves using natural catalysts—enzymes—to perform chemical transformations. Enzymes are “molecular machines” that have evolved to operate with extraordinary specificity and efficiency under very mild conditions (e.g., in water at room temperature).74 This approach can dramatically simplify synthesis, reduce energy consumption, and minimize waste. The synthesis of the diabetes drug sitagliptin was famously revolutionized by Merck, which replaced a complex chemical step involving a precious metal (rhodium) catalyst with a single, highly efficient step using an engineered transaminase enzyme.101

- Organocatalysis: This branch of catalysis uses small, metal-free organic molecules to catalyze reactions. This is advantageous as it avoids the use of expensive and potentially toxic heavy metals, which can contaminate the final API and require extensive purification to remove.101

- Photocatalysis and Electrosynthesis: These emerging fields use light or electricity, respectively, as the energy source to drive chemical reactions. They offer novel and sustainable pathways for constructing complex molecules.105

Catalyst Design and Integration

The discovery of new catalysts is being accelerated by digital tools, while their practical application is being enhanced by integration with advanced manufacturing platforms.

- Computational Design: Scientists are now using computational quantum mechanics, specifically Density Functional Theory (DFT), and machine learning algorithms to design and screen new catalyst candidates in silico.101 This allows them to predict a catalyst’s performance before it is ever synthesized in the lab, dramatically accelerating the discovery and optimization cycle.

- Immobilization and Flow Chemistry: A major practical challenge with many catalysts is separating them from the reaction mixture after the reaction is complete. To solve this, catalysts can be immobilized by anchoring them to a solid support material. These immobilized catalysts can then be packed into a continuous flow reactor. This setup allows the reaction mixture to flow continuously over the catalyst, simplifying purification, enabling the easy recovery and reuse of the expensive catalyst, and providing the stable, controlled environment needed for robust, long-term manufacturing operations.101

This synergy—using digital tools like CAR to design better chemical pathways and then executing those pathways using advanced catalysts in modern manufacturing platforms like continuous flow reactors—represents the frontier of API synthesis. While CM and automation are critical for optimizing the execution of a given process, catalysis optimizes the fundamental chemistry itself. A single catalytic breakthrough can have a more profound impact on efficiency and sustainability than any downstream optimization. For example, inventing a new catalyst that allows a five-step synthesis to be accomplished in three steps provides a far greater benefit in terms of cost, waste, and throughput than simply running the original, less efficient five-step process in a continuous reactor. Therefore, continued investment in fundamental catalysis research and development offers the highest potential return in the pursuit of ultimate manufacturing excellence.

Section 6: Strategic Outlook and Recommendations

The convergence of advanced manufacturing paradigms, digital technologies, and innovative chemical synthesis is not merely an incremental evolution; it represents a fundamental reshaping of the API manufacturing landscape. The insights gleaned from these industry-wide transformations point toward a future characterized by greater personalization, enhanced supply chain resilience, and a new set of competitive dynamics. For stakeholders to navigate this future successfully, a clear strategic blueprint is required—one that moves beyond piecemeal technology adoption to a holistic integration of these powerful new capabilities.

6.1 The Future of API Manufacturing: Personalized Medicine and On-Demand Production

The long-term trajectory of pharmaceutical development is a clear shift away from “one-size-fits-all” blockbuster drugs and toward precision medicine. This approach involves tailoring therapeutic treatments to individual patients or small patient subgroups based on their unique genetic, biomarker, lifestyle, and environmental profiles.106 This paradigm has profound implications for API manufacturing.

The Shift to Precision Medicine

The rise of personalized medicine creates a demand for a fundamentally different manufacturing model: one that can efficiently produce a wide variety of APIs in small, highly customized batches.106 This is a direct challenge to the traditional model, which is optimized for producing massive quantities of a single product.

Enabling Technologies for Personalization

The technologies and strategies discussed throughout this report are the essential enablers of this future. Flexible, modular Continuous Manufacturing systems are perfectly suited for this new reality. A single, reconfigurable CM platform could potentially produce a variety of different personalized APIs by simply changing the input materials and process parameters, a concept known as “scale-out” rather than “scale-up”.107 When combined with AI-driven process control for rapid optimization and emerging technologies like the 3D printing of final dosage forms, a vision of on-demand, decentralized manufacturing begins to emerge.106 This could ultimately lead to a future where customized medicines are produced locally, perhaps even within hospital pharmacies, to meet the specific, immediate needs of a patient.106 While this vision faces significant technical, logistical, and regulatory hurdles—including the need for hyper-flexible supply chains and new frameworks for point-of-care manufacturing—the foundational technologies are rapidly maturing.107

6.2 Building Resilient Supply Chains

If personalized medicine is the long-term “pull” for technological adoption, supply chain resilience is the immediate and urgent “push.” The COVID-19 pandemic served as a stark wake-up call, exposing the profound fragility of the global pharmaceutical supply chain.71 The heavy reliance on a small number of countries, particularly China and India, for the vast majority of the world’s critical APIs created a strategic vulnerability that resulted in widespread drug shortages and highlighted significant national security risks.71

Technology as the Solution

Smarter manufacturing technologies are the most potent tool for addressing this vulnerability. As previously discussed, the favorable economics of agile, modular CM plants—with their lower capital costs and high degree of automation—make it viable to reshore or “near-shore” critical API production back to regions like North America and Europe.56 By shifting the competitive basis from low-cost labor to technological prowess, these advanced manufacturing platforms enable the creation of a more diversified, secure, and resilient supply network.

The Role of Business Intelligence

Navigating this complex global landscape also requires sophisticated market and competitive intelligence. Platforms such as DrugPatentWatch provide an essential service by aggregating and analyzing data on API vendors, global patent filings, clinical trials, and regulatory statuses.108 This intelligence allows companies to make more informed strategic decisions regarding sourcing partners, portfolio management, identifying market entry opportunities for generic APIs, and anticipating competitive threats, which is a critical component of building a robust and forward-looking supply chain strategy.

6.3 A Blueprint for Optimization: Actionable Recommendations

Synthesizing the findings of this report, a clear blueprint emerges for stakeholders seeking to achieve and sustain a competitive advantage in API manufacturing. The following five recommendations constitute a holistic strategy for navigating the industry’s transformation.

- 1. Embrace QbD as Corporate Culture: Quality by Design and its enabler, PAT, must be elevated from a regulatory compliance function to the central, science-driven philosophy guiding all process development and manufacturing activities. This deep, fundamental understanding of product and process is the non-negotiable foundation upon which all other advanced technologies are built. Without it, attempts at implementing CM or AI will be inefficient, ineffective, and ultimately un-validatable.

- 2. Invest Strategically in Continuous Manufacturing: For existing high-volume products, companies should develop a clear, phased roadmap for transitioning key process steps from batch to continuous. For all new products entering the development pipeline, the process should be designed for CM from the outset. Investment should prioritize modular and flexible platforms that can be adapted for multiple products, maximizing the long-term value and utility of the capital assets.

- 3. Build a Digital Infrastructure: A company’s ability to compete will increasingly depend on its ability to manage data. This requires strategic investment in the foundational digital infrastructure: a comprehensive network of sensors (IIoT), integrated data management systems, and, most importantly, the analytical talent required to transform raw data into actionable process intelligence. The implementation should be pragmatic, starting with high-value, achievable use cases like predictive maintenance and real-time process monitoring before progressing toward full, closed-loop AI-driven process control.

- 4. Champion Green Chemistry as a Profit Center: Green Chemistry principles should be integrated into the earliest stages of process design and development. R&D teams should be incentivized and equipped with metrics (like PMI) to discover and implement more sustainable synthetic routes. Leadership must champion the understanding that the greenest process is almost invariably the most efficient, robust, and profitable one in the long run.

- 5. Foster a Future-Ready Workforce: The technological shift to the smart factory necessitates a parallel shift in human capital. Companies must proactively invest in comprehensive training and reskilling programs to equip their workforce with the critical skills needed for the future: data science, automation engineering, robotics, and systems-level thinking. The successful transition to the factory of the future is as much a human and organizational challenge as it is a technical one.

The simultaneous maturation of these distinct but interconnected trends—Continuous Manufacturing, Artificial Intelligence, and Green Chemistry—is creating a true inflection point. These forces are mutually reinforcing: CM provides the ideal, data-rich environment for AI to thrive; AI provides the advanced control intelligence needed to manage complex CM systems; and Green Chemistry provides the inherently superior chemical pathways that allow these advanced platforms to operate at their maximum potential. Companies that recognize and harness this powerful convergence will not only achieve new levels of operational excellence but will also be positioned to lead the next generation of pharmaceutical manufacturing. This new paradigm, characterized by smaller, more agile, and technologically sophisticated operations, also has the potential to lower the traditional barriers to entry in API manufacturing. This could lead to a “democratization” of production, where smaller, more innovative companies can effectively compete with established giants, not on sheer scale, but on the speed, flexibility, and intelligence of their manufacturing technology. This poses a direct strategic challenge to the capital-intensive, legacy models of the past and signals a dynamic and transformative era ahead for the entire industry.

Works cited

- Brazilian national production of active pharmaceutical ingredients: regulatory and strategic framework – ResearchGate, accessed August 3, 2025, https://www.researchgate.net/publication/376565968_Brazilian_national_production_of_active_pharmaceutical_ingredients_regulatory_and_strategic_framework

- Active Pharmaceutical Ingredient (API) Definition – Law Insider, accessed August 3, 2025, https://www.lawinsider.com/dictionary/active-pharmaceutical-ingredient-api

- AI for High Quality Small Molecule API Manufacturing – Basetwo AI, accessed August 3, 2025, https://www.basetwo.ai/blogs/small-molecule-manufacturing-streamlined-with-ai

- Active Pharmaceutical Ingredients – Manufacturing Process, Technology, Applications, Patent, Consultants, Company Profiles, Policy,Reports, Market, accessed August 3, 2025, https://www.primaryinfo.com/projects/active-pharmaceutical-ingredients.htm

- Enhancing Drug Development: A Comprehensive Guide to API …, accessed August 3, 2025, https://www.seqens.com/knowledge-center/enhancing-drug-development-comprehensive-guide/

- Active Pharmaceutical Ingredient (API) Process Development | Esco Aster, accessed August 3, 2025, https://escoaster.com/Products/api-process-development

- Manufacturing processes for APIs, accessed August 3, 2025, https://vaibhavfinechem.com/blog-detail/manufacturing-processes-for-apis

- API Synthesis – BOC Sciences, accessed August 3, 2025, https://www.solutions.bocsci.com/api-synthesis.htm

- API Synthesis – Protheragen, accessed August 3, 2025, https://www.protheragen.ai/api-synthesis.html

- Advanced therapy medicinal products: Overview – EMA – European Union, accessed August 3, 2025, https://www.ema.europa.eu/en/human-regulatory-overview/advanced-therapy-medicinal-products-overview

- EMA Guideline On Clinical-Stage ATMPs Comes Into Effect On The …, accessed August 3, 2025, https://www.cellandgene.com/doc/ema-guideline-on-clinical-stage-atmps-comes-into-effect-on-the-verge-of-convergence-0001

- EMA adopts guideline on requirements for clinical-stage ATMPs – RAPS, accessed August 3, 2025, https://www.raps.org/news-and-articles/news-articles/2025/2/ema-adopts-guideline-on-requirements-for-clinical

- www.bhagwatipharma.com, accessed August 3, 2025, https://www.bhagwatipharma.com/api-plant-equipment-active-pharmaceutical-ingredient-plant/#:~:text=The%20Active%20Pharmaceutical%20Ingredient%20(API,drying%2C%20milling%2C%20and%20labeling.

- API Plant Equipment – Active Pharmaceutical Ingredient Plant, accessed August 3, 2025, https://www.bhagwatipharma.com/api-plant-equipment-active-pharmaceutical-ingredient-plant/

- What Are APIs in Pharmaceutical Manufacturing? – Bachem, accessed August 3, 2025, https://www.bachem.com/articles/blog/what-are-apis-in-pharmaceutical-manufacturing/

- Understanding Small Molecule API Purification in the Pharmaceutical Industry, accessed August 3, 2025, https://www.seppure.com/blogs/understanding-small-molecule-api-purification-in-the-pharmaceutical-industry

- The Development of API Manufacturing Processes – Targets and Strategies – ResearchGate, accessed August 3, 2025, https://www.researchgate.net/publication/233563206_The_Development_of_API_Manufacturing_Processes_-_Targets_and_Strategies

- The Challenges of Increased Complexity in API Development and Manufacture, accessed August 3, 2025, https://international-pharma.com/the-challenges-of-increased-complexity-in-api-development-and-manufacture/

- The Challenges of Increased Complexity in API Development and …, accessed August 3, 2025, https://international-pharma.com/wp-content/uploads/2023/01/The-Challenges-of-Increased-Complexity-in-API-Development-and-Manufacture.pdf

- Scaling API Synthesis: The Crucial Bridge Between Discovery and …, accessed August 3, 2025, https://pharmafeatures.com/scaling-api-synthesis-the-crucial-bridge-between-discovery-and-delivery/

- Impurity Profiling in Drug Development – Veeprho, accessed August 3, 2025, https://veeprho.com/impurity-profiling-in-drug-development/

- Recent trends in the impurity profile of pharmaceuticals – PMC, accessed August 3, 2025, https://pmc.ncbi.nlm.nih.gov/articles/PMC3255420/

- Q 7 Good Manufacturing Practice for Active Pharmaceutical Ingredients – EMA, accessed August 3, 2025, https://www.ema.europa.eu/en/documents/scientific-guideline/ich-q-7-good-manufacturing-practice-active-pharmaceutical-ingredients-step-5_en.pdf

- Strategies for Managing API Impurities in Drug Development …, accessed August 3, 2025, https://pharmatimesofficial.com/project/strategies-for-managing-api-impurities-in-drug-development/

- How Reagent Purity Impacts API Manufacturing for Oligonucleotides and Peptides, accessed August 3, 2025, https://www.dcatvci.org/sponsored/high-purity-reagents-api-manufacturing-oligonucleotides-peptides/

- Impact of API (Active Pharmaceutical Ingredient … – Hilaris Publisher, accessed August 3, 2025, https://www.hilarispublisher.com/open-access/impact-of-api-active-pharmaceutical-ingredient-source-selection-on-generic-drug-products-2167-7689-1000136.pdf

- (PDF) Impurity profile: Significance in Active Pharmaceutical Ingredient – ResearchGate, accessed August 3, 2025, https://www.researchgate.net/publication/215866887_Impurity_profile_Significance_in_Active_Pharmaceutical_Ingredient

- Active pharmaceutical ingredient (API) chemicals: a critical review of current biotechnological approaches – PMC, accessed August 3, 2025, https://pmc.ncbi.nlm.nih.gov/articles/PMC8973766/

- 12 Principles of Green Chemistry – American Chemical Society, accessed August 3, 2025, https://www.acs.org/green-chemistry-sustainability/principles/12-principles-of-green-chemistry.html

- Decarbonizing API manufacturing: Unpacking the cost and regulatory requirements, accessed August 3, 2025, https://www.mckinsey.com/industries/life-sciences/our-insights/decarbonizing-api-manufacturing-unpacking-the-cost-and-regulatory-requirements

- QbD in API Manufacturing – All About Drugs, accessed August 3, 2025, https://www.allfordrugs.com/qbd-in-api-manufacturing/

- Understanding Pharmaceutical Quality by Design – PMC, accessed August 3, 2025, https://pmc.ncbi.nlm.nih.gov/articles/PMC4070262/

- Journey of an API: Supporting quality by design in API development, accessed August 3, 2025, https://www.sterlingpharmasolutions.com/knowledge-hub/api-manufacturing/journey-of-an-api-supporting-quality-by-design-in-api-development/

- Quality by Design in API Manufacturing, accessed August 3, 2025, https://www.gmp-compliance.org/files/eca/userFiles/seminarpdf/ECA-QBD-Drug-Product-Development-API-Manufacturing.pdf

- QbD in API Manufacturing – Pharmaceutical Technology, accessed August 3, 2025, https://www.pharmtech.com/view/qbd-api-manufacturing

- Implementation of QbD in API development | Request PDF, accessed August 3, 2025, https://www.researchgate.net/publication/289868375_Implementation_of_QbD_in_API_development

- Process Analytical Technology and Quality by Design – Ondalys, accessed August 3, 2025, https://ondalys.fr/en/data-analysis/applications/pat-qbd/

- Quality by design | European Medicines Agency (EMA), accessed August 3, 2025, https://www.ema.europa.eu/en/human-regulatory-overview/research-development/quality-design

- Process Analytical Technology (PAT) – Enhance Quality and Efficiency, accessed August 3, 2025, https://www.mt.com/in/en/home/applications/L1_AutoChem_Applications/L2_PAT.html

- Process Analytical Technology (PAT) | Bruker, accessed August 3, 2025, https://www.bruker.com/en/products-and-solutions/process-analytical-technology.html

- PAT in Pharma: A Comprehensive Guide – Number Analytics, accessed August 3, 2025, https://www.numberanalytics.com/blog/ultimate-guide-to-process-analytical-technology-in-pharmaceutical-sciences

- Quality by Design: Industrial Case Studies on Defining and Implementing Design Space for Pharmaceutical Processes (Part 2) – BioPharm International, accessed August 3, 2025, https://www.biopharminternational.com/view/quality-design-industrial-case-studies-defining-and-implementing-design-space-pharmaceutical-process

- QbD and PAT: From Science to Compliance – European Pharmaceutical Review, accessed August 3, 2025, https://www.europeanpharmaceuticalreview.com/article/789/qbd-pat-science-compliance/

- Ph. Eur. Draft on PAT – ECA Academy, accessed August 3, 2025, https://www.gmp-compliance.org/gmp-news/ph-eur-draft-on-pat

- Green Chemistry: A More Sustainable Approach to Medicine Development – Pfizer, accessed August 3, 2025, https://www.pfizer.com/news/articles/green_chemistry_a_more_sustainable_approach_to_medicine_development

- Principles of green chemistry: Advancing pharma sustainability, accessed August 3, 2025, https://instituteofsustainabilitystudies.com/insights/guides/principles-of-green-chemistry-advancing-pharma-sustainability/

- Green Pharma Revolution: Eco-Friendly Strategies for API …, accessed August 3, 2025, https://pharmafeatures.com/green-pharma-revolution-eco-friendly-strategies-for-api-manufacturing-in-modern-medicine/

- Harnessing the 12 Green Chemistry Principles for Sustainable Antiparasitic Drugs: Toward the One Health Approach – PMC – PubMed Central, accessed August 3, 2025, https://pmc.ncbi.nlm.nih.gov/articles/PMC11184551/

- The Role of Green Chemistry in Generic Drug Development: A …, accessed August 3, 2025, https://www.drugpatentwatch.com/blog/the-role-of-green-chemistry-in-generic-drug-development-a-sustainable-approach-to-medicine/

- Sustainability and Green Chemistry in Drug Development – Company Connect Consultancy, accessed August 3, 2025, https://www.companysconnects.com/post/sustainability-and-green-chemistry-in-drug-development

- Evolving the Green Chemist’s Toolbox for APIs Manufacturing – SEQENS, accessed August 3, 2025, https://www.seqens.com/knowledge-center/evolving-the-green-chemists-toolbox-for-apis-manufacturing/

- Presidential Green Chemistry Challenge: 2002 Greener Synthetic Pathways Award, accessed August 3, 2025, https://www.epa.gov/greenchemistry/presidential-green-chemistry-challenge-2002-greener-synthetic-pathways-award

- The Impact of Process Chemists and Engineers on Green Chemistry – ACS Publications, accessed August 3, 2025, https://pubs.acs.org/doi/10.1021/op800259p

- Redesign of the Sertraline Production Process – Green Chemistry For Sustainability, accessed August 3, 2025, https://chemistryforsustainability.org/safer-alternatives/redesign-sertraline-production-process

- Continuous vs. Batch Manufacturing: What’s the Difference? – News-Medical.net, accessed August 3, 2025, https://www.news-medical.net/life-sciences/Pharmaceutical-Continuous-Manufacturing-vs-Batch-Manufacturing-Whats-the-Difference.aspx

- Continuous Manufacturing of Active Pharmaceutical Ingredients: Current Trends and Perspectives | Request PDF – ResearchGate, accessed August 3, 2025, https://www.researchgate.net/publication/377022338_Continuous_Manufacturing_of_Active_Pharmaceutical_Ingredients_Current_Trends_and_Perspectives

- Review: Continuous Manufacturing of Small Molecule Solid Oral …, accessed August 3, 2025, https://pmc.ncbi.nlm.nih.gov/articles/PMC8400279/

- End-to-End: Implementing Continuous Manufacturing in the Pharmaceutical Industry | Yokogawa America, accessed August 3, 2025, https://www.yokogawa.com/us/library/resources/media-publications/end-to-end-implementing-continuous-manufacturing-in-the-pharmaceutical-industry/

- Continuous Manufacturing Process and Its Impact on Pharma Manufacturing | Article, accessed August 3, 2025, https://api.drreddys.com/articles/continuous-manufacturing-process-and-its-impact-pharma-manufacturing

- Continuous vs. Batch Processes: Which is Best for Your …, accessed August 3, 2025, https://amarequip.com/blog-details/continuous-vs-batch-processes-which-is-best-for-your-manufacturing-needs

- Continuous vs. Batch Process: What Are the Differences? – Katana MRP, accessed August 3, 2025, https://katanamrp.com/blog/continuous-vs-batch-process/

- 5 reasons to adopt continuous processing in pharmaceutical … – WSP, accessed August 3, 2025, https://www.wsp.com/en-gb/insights/how-continuous-processing-can-optimise-pharmaceutical-manufacturing

- Continuous Manufacturing • Pharma – IMA Group, accessed August 3, 2025, https://ima.it/pharma/continuous-manufacturing/

- Economic Analysis of Integrated Continuous and Batch …, accessed August 3, 2025, https://pubs.acs.org/doi/10.1021/ie2006752

- Economic Analysis of Integrated Continuous and Batch Pharmaceutical Manufacturing: A Case Study | Industrial & Engineering Chemistry Research – ACS Publications, accessed August 3, 2025, https://pubs.acs.org/doi/abs/10.1021/ie2006752

- Continuous Versus Batch: A Pharmaceutical Manufacturing Q&A, accessed August 3, 2025, https://www.tabletscapsules.com/3641-Technical-Articles/581452-Continuous-Versus-Batch-Pharmaceutical-Manufacturing-Q-A/

- Revolutionizing Drug Production: The Rise of Continuous …, accessed August 3, 2025, https://pharmafeatures.com/revolutionizing-drug-production-the-rise-of-continuous-manufacturing-for-active-pharmaceutical-ingredients/

- Enhancing Pharmaceutical Quality with Continuous Manufacturing – Redzone, accessed August 3, 2025, https://rzsoftware.com/continuous-manufacturing-pharmaceutical-quality/

- FDA Guidance on Continuous Manufacturing of Drug Substances …, accessed August 3, 2025, https://www.goodwinlaw.com/en/insights/blogs/2023/04/fda-guidance-on-continuous-manufacturing-of-drug-substances-and-drug-products

- Continuous Manufacturing in Pharma: FDA Perspective – Food and …, accessed August 3, 2025, https://www.fdli.org/2019/09/continuous-manufacturing-in-pharma-fda-perspective/

- How Smarter API Manufacturing Is Eating Big Pharma’s Lunch – Drug Patent Watch, accessed August 3, 2025, https://www.drugpatentwatch.com/blog/how-smarter-api-manufacturing-is-eating-big-pharmas-lunch/

- Process intensification for biomanufacturing – Cytiva, accessed August 3, 2025, https://www.cytivalifesciences.com/en/us/solutions/bioprocessing/products-and-solutions/Process-Intensification

- Streamlining Pharmaceutical Synthesis: The Science of Process Intensification in High-Yield API Production – PharmaFeatures, accessed August 3, 2025, https://pharmafeatures.com/streamlining-pharmaceutical-synthesis-the-science-of-process-intensification-in-high-yield-api-production/

- Innovations to API Synthesis | The Pharma Master, accessed August 3, 2025, https://www.thepharmamaster.com/innovationstoapisynthesis

- Boosting Efficiency with Process Intensification – Number Analytics, accessed August 3, 2025, https://www.numberanalytics.com/blog/process-intensification-strategies