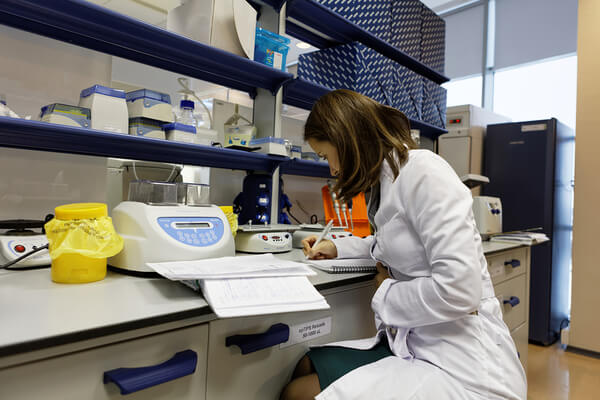

In the vast and complex ecosystem of modern healthcare, few forces have been as democratizing as the generic drug industry. It’s a world built on a simple yet powerful premise: once the intellectual property shield of a blockbuster brand-name drug expires, equivalent, affordable alternatives can enter the market, dramatically reducing costs for patients and healthcare systems alike. Yet, behind this simple premise lies a labyrinth of scientific, regulatory, and manufacturing challenges that are anything but simple.

The journey from identifying a patent-expired drug to launching a successful generic equivalent is a high-stakes race against time, competitors, and the very laws of chemistry and physics. It’s a field where fortunes are made and lost not on discovering new molecules, but on flawlessly reverse-engineering and replicating existing ones. The core of this challenge? Formulation. It’s the art and science of combining an Active Pharmaceutical Ingredient (API) with a carefully selected cast of ‘inactive’ ingredients, or excipients, to create a final product that is not just chemically identical but, crucially, therapeutically identical to its brand-name predecessor.

This article will take you on an in-depth journey through this labyrinth. We won’t just skim the surface; we’ll plunge into the granular details of the formulation process, exploring the immense hurdles that developers face. To ground our exploration in reality, we will anchor our discussion in a real-world case study: the development of a generic version of Metoprolol Succinate Extended-Release (ER) tablets, a notoriously difficult-to-formulate product. Through this lens, we will dissect the entire development lifecycle—from patent intelligence and pre-formulation to scale-up, manufacturing, and the final, nerve-wracking regulatory submission.

Prepare to go beyond the headlines of “cheap drugs” and discover the immense scientific rigor, strategic thinking, and relentless problem-solving required to succeed in the world of generic pharmaceuticals. Whether you are a business leader aiming to carve out a niche, a scientist wrestling with a stubborn dissolution profile, or a regulatory professional navigating the complex approval pathways, this deep dive will equip you with the insights needed to turn formulation challenges into a powerful competitive advantage.

Introduction: The High-Stakes World of Generic Pharmaceuticals

The global pharmaceutical market is often seen as a tale of two cities. On one side, you have the glittering metropolis of innovator, brand-name drugs, born from billions of dollars in R&D and protected by a formidable wall of patents. On the other, you have the bustling, dynamic, and intensely competitive world of generic drugs. While they may not grab the same headlines as breakthrough cures, their impact is arguably just as profound.

The Generic Promise: More Than Just a Cheaper Pill

The value proposition of generics is crystal clear: access and affordability. When a generic drug enters the market, it can drive down the price of that medication by as much as 85% or more [1]. This isn’t just a minor discount; it’s a fundamental shift in the economics of healthcare.

The Socio-Economic Impact of Generics

Consider the numbers. In the United States alone, generic drugs saved the healthcare system $408 billion in 2022 and over $2.9 trillion in the last decade [2]. These are not abstract figures. They represent real-world benefits: elderly patients on fixed incomes who can suddenly afford their heart medication, state-funded health programs that can stretch their budgets to cover more citizens, and families who are spared from making agonizing choices between their health and their financial stability.

Generics are the workhorses of the modern pharmacy. In the U.S., they account for approximately 90% of all prescriptions filled, yet they represent only about 18% of total prescription drug spending [2]. This incredible efficiency is the engine that allows healthcare systems to absorb the high cost of new, innovative therapies while still providing essential medicines to the broader population. But this engine doesn’t run on its own. It’s fueled by intense competition and the relentless pursuit of scientific parity.

The Competitive Landscape: A Race Against Time and Patents

The moment a blockbuster drug’s primary patents begin to expire, a starting gun fires. Multiple generic companies, who have often been working for years in anticipation of this date, rush to be the first to secure approval from regulatory bodies like the U.S. Food and Drug Administration (FDA). The prize for the first company to file a successful Abbreviated New Drug Application (ANDA) can be immense: a 180-day period of market exclusivity, during which they can capture significant market share before other generic competitors are allowed to enter [3].

This creates a pressure-cooker environment. Every decision is critical, and every delay can cost millions in lost revenue. The competitive landscape isn’t just about being fast; it’s about being right. A flawed formulation, a failed bioequivalence study, or a manufacturing process that can’t be scaled up can mean missing that crucial launch window, turning a potential blockbuster generic into a financial write-off.

The Formulation Conundrum: The Core Challenge of “Sameness”

At the heart of every generic drug’s journey is a single, defining mandate: it must be “the same as” the innovator product, also known as the Reference Listed Drug (RLD). But what does “sameness” truly mean in a pharmaceutical context? It’s far more than just containing the same amount of the same active ingredient.

Defining Bioequivalence: The Bedrock of Generic Approval

The FDA defines bioequivalence as “the absence of a significant difference in the rate and extent to which the active ingredient or active moiety in pharmaceutical equivalents or pharmaceutical alternatives becomes available at the site of drug action when administered at the same molar dose under similar conditions in an appropriately designed study” [4].

Let’s break that down. It’s not enough for a generic tablet to have 50 mg of an API if the RLD also has 50 mg. The generic tablet must release that API into the bloodstream at the same rate (how fast) and to the same extent (how much) as the RLD. This pharmacokinetic (PK) profile—measured primarily by the maximum plasma concentration (C_max) and the total drug exposure over time (Area Under the Curve, or AUC)—is the true fingerprint of a drug’s performance in the body. The generic’s fingerprint must be a near-perfect match to the original. If the generic releases the drug too quickly, it could lead to toxic side effects. If it releases it too slowly, the drug may not be effective.

Why Reverse Engineering is an Art, Not Just a Science

Achieving this bioequivalent fingerprint is the central formulation conundrum. Generic companies don’t have access to the innovator’s proprietary development data, their manufacturing secrets, or the exact specifications of their raw materials. They are, in essence, trying to recreate a masterpiece with only the finished painting to study.

This process, known as deformulation or reverse engineering, is a sophisticated form of scientific detective work. Scientists must use advanced analytical techniques to carefully dissect the RLD, identifying not just the API, but every single excipient—the binders, fillers, disintegrants, lubricants, and coatings. They must determine the quantity of each, and more importantly, hypothesize their function within the formulation. Are they using a specific grade of a polymer to control the drug’s release? Is there a particular lubricant used to ensure the tablets don’t stick to the manufacturing press? Is the API in a specific crystalline form, or polymorph, that affects its solubility?

Every detail matters. The innovator company has spent a decade and billions of dollars optimizing their product. The generic company has a fraction of that time and budget to get it exactly right. It’s a challenge that requires a unique blend of analytical chemistry, material science, process engineering, and sheer ingenuity.

Setting the Stage: Introducing Our Case Study – “Metoprolol Succinate Extended-Release Tablets”

To truly appreciate the depth of these challenges, we need a concrete example. Throughout this article, we will use the development of generic Metoprolol Succinate ER tablets as our guiding case study. This product, a beta-blocker used to treat high blood pressure and heart failure, is a perfect illustration of the complexities of modern generic formulation.

Why Metoprolol Succinate? A Perfect Storm of Challenges

Metoprolol Succinate ER presents a confluence of difficulties that make it a classic case study in the industry:

- Extended-Release Technology: It’s not an immediate-release tablet. It’s designed to release the drug slowly over 24 hours, providing consistent therapeutic levels with once-a-day dosing. Mimicking this sophisticated release mechanism is a monumental challenge.

- High Solubility API: Metoprolol succinate is very soluble in water. Creating an extended-release profile for a highly soluble drug is like trying to build a dam out of sand; the drug constantly wants to dissolve and escape quickly.

- Complex Drug Delivery System: The innovator product, Toprol-XL®, uses a patented, multi-particulate drug delivery system, where the drug is contained within thousands of tiny pellets, each individually coated to control the release rate. These pellets are then compressed into a tablet.

- Food Effect: The drug’s absorption can be affected by food, meaning bioequivalence studies must be carefully designed to test the product’s performance in both fed and fasting states.

Successfully creating a generic version of this product is a masterclass in formulation science. It requires not just matching the ingredients, but perfectly replicating the function of a highly engineered drug delivery device.

The Brand-Name Benchmark: Toprol-XL®

The innovator product, AstraZeneca’s Toprol-XL®, set a very high bar. It utilizes a sophisticated system where metoprolol succinate is formulated into controlled-release pellets. These pellets are then compressed into a tablet that, upon ingestion, disintegrates to release the individual pellets, which then gradually release the drug as they pass through the gastrointestinal tract. This design ensures a consistent plasma concentration profile over 24 hours, minimizing the peaks and troughs associated with immediate-release formulations and improving patient compliance [5].

Any generic developer aiming to compete must create a system that, while likely using a different proprietary method to avoid patent infringement, delivers an identical in vivo performance. How do they do it? That is the story we are about to unfold.

The Pre-Formulation Gauntlet: Laying the Foundation for Success

Before a single gram of API is mixed with an excipient, the most critical work begins. The pre-formulation stage is the strategic heart of generic development. It’s where business intelligence meets hard science, and where decisions made can dictate the success or failure of the entire project. This phase is a gauntlet of patent analysis, deep physicochemical characterization, and meticulous reverse engineering. Rushing through this stage is a recipe for disaster; mastering it lays a robust foundation for everything that follows.

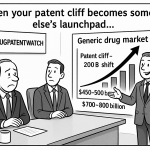

The Patent Cliff and the Opportunity Window

The generic drug lifecycle begins not in the lab, but in the dense, legalistic world of patent databases. The “patent cliff” refers to the point at which a blockbuster drug’s market exclusivity and patent protection expire, leading to a potential sharp drop in revenue as generic competitors flood the market. For generic companies, this cliff is an opportunity.

The Role of Patent Intelligence: Using Tools Like DrugPatentWatch

Identifying the right opportunity at the right time is paramount. This requires sophisticated patent intelligence. Companies can’t simply look up a single patent expiration date. Innovator products are often protected by a “patent estate”—a complex web of multiple patents covering not just the core API molecule, but also its crystalline forms (polymorphs), the specific formulation, the manufacturing process, and even its approved uses (methods of use).

This is where specialized services become invaluable. Platforms like DrugPatentWatch provide comprehensive intelligence that goes far beyond a simple expiration date. They offer detailed data on patent litigation, FDA Orange Book listings, exclusivity periods, and potential patent challenges (like Paragraph IV filings). For a business professional, this information is gold. It helps answer critical questions:

- Which patents are the most significant barriers to entry?

- Are there potential weaknesses in the innovator’s patent estate that could be challenged in court?

- When is the true, unencumbered date for a generic launch?

- How many other generic companies are also targeting this product?

For our Metoprolol Succinate ER case study, a deep dive using such a tool would reveal patents not just on the metoprolol molecule, but specifically on the extended-release technology. A generic company must navigate this minefield carefully, designing a formulation that is bioequivalent without infringing on any active patents. This is often referred to as “designing around” the patent.

Deconstructing the Innovator’s Patent Estate: Formulation, Process, and Polymorphs

Let’s imagine our team is targeting Toprol-XL®. The first step is to deconstruct its patent protection. We would find patents related to the Geomatrix™ technology, which describes a specific way of creating controlled-release pellets. This immediately tells our formulators that we cannot use that exact technology. We must develop our own proprietary ER system.

Furthermore, we might find patents on specific polymorphs of metoprolol succinate. A polymorph is a specific crystalline structure of the API. Different polymorphs of the same molecule can have vastly different properties, including solubility, stability, and bioavailability. The innovator may have patented a particularly stable and effective polymorph. Our team would then need to either find a non-infringing polymorph that still works, or challenge the validity of the innovator’s patent.

This analysis shapes the entire R&D strategy. It defines the “sandbox” within which the formulators must play. It’s a strategic process of elimination that narrows down the viable technological paths before the first experiment is even conducted.

Characterizing the Active Pharmaceutical Ingredient (API)

With a clear understanding of the patent landscape, the focus shifts to the star of the show: the API. Sourcing or synthesizing the API is just the first step. The real work lies in understanding its physicochemical properties in exhaustive detail. Simply meeting the United States Pharmacopeia (USP) standard for metoprolol succinate is not enough. A generic developer needs to understand the API as well as, or even better than, the innovator did.

Beyond the Chemical Structure: Physicochemical Properties Matter

The performance of the final drug product is inextricably linked to the physical properties of the API powder used to make it. Key properties include:

- Solubility: How well does the API dissolve in different pH environments, mimicking its journey through the stomach and intestines? Metoprolol succinate is highly soluble, which, as mentioned, makes creating an ER formulation a challenge.

- Permeability: How well does the dissolved API pass through the intestinal wall into the bloodstream? Solubility and permeability are the two factors of the Biopharmaceutics Classification System (BCS), which helps predict a drug’s absorption characteristics [6]. Metoprolol is a BCS Class I drug (high solubility, high permeability), which is generally good for absorption but complicates controlled release.

- Hygroscopicity: Does the API absorb moisture from the air? This can affect its stability, flowability during manufacturing, and even its crystalline structure.

- Flowability: How well does the API powder flow? Poor flow can lead to inconsistencies when filling capsules or feeding tablet presses, resulting in tablets with variable dosages—a critical failure point.

Each of these properties must be quantified and understood. This data forms the input for the formulation design.

Polymorphism: The Hidden Variable That Can Make or Break a Generic

Of all the API properties, polymorphism is perhaps the most critical and treacherous. It’s a phenomenon where a single chemical compound can crystallize into multiple different solid-state forms. Think of carbon, which can exist as soft, grey graphite or as hard, transparent diamond. Both are 100% carbon, but their crystal structures give them wildly different properties.

The same is true for APIs. One polymorph might be highly soluble and bioavailable, while another (a “disappearing polymorph”) might be so stable and insoluble that it’s therapeutically useless. The innovator company will have spent enormous effort to identify, select, and consistently manufacture the optimal polymorph.

The generic developer must do the same. They need to screen for all possible polymorphs of metoprolol succinate. They must then develop a crystallization process that reliably produces the desired form and ensures it doesn’t convert to another, less desirable form during manufacturing or storage. A famous case is that of the antiviral drug Ritonavir. A new, more stable, and less soluble polymorph unexpectedly appeared years after the product launch, rendering the capsules ineffective and forcing a massive recall and reformulation effort [7]. For a generic company, such a mistake would be fatal.

Particle Size, Solubility, and Stability: The Triumvirate of API Challenges

The particle size distribution (PSD) of the API is another crucial factor. Smaller particles have a larger surface area, which generally leads to faster dissolution. For a highly soluble drug like metoprolol, the PSD might be less critical for dissolution rate but could be very important for manufacturing processability (e.g., blend uniformity).

Our formulators need to establish a target PSD for their metoprolol succinate API and ensure their supplier can provide it consistently, batch after batch. They also need to conduct rigorous stability studies on the API alone. How does it hold up under heat, humidity, and light? Does it degrade? Does it change its polymorphic form? Any instability in the raw API will invariably lead to an unstable final product. This detailed characterization creates a “fingerprint” of the target API, a benchmark against which all sourced material will be judged.

Deformulation: Reverse Engineering the Innovator Product

While the API is being characterized, a parallel and equally important process is underway: the deformulation of the RLD, Toprol-XL®. This is the meticulous process of taking the innovator’s product apart to understand how it was made.

Advanced Analytical Techniques: Peeling Back the Layers of the Brand-Name Drug

Deformulation is a high-tech endeavor. Scientists employ a battery of sophisticated analytical techniques to dissect the RLD:

- High-Performance Liquid Chromatography (HPLC): Used to separate, identify, and quantify the API and any potential impurities or degradation products.

- Mass Spectrometry (MS): Often coupled with HPLC (LC-MS), it helps determine the exact molecular weight and structure of the components, confirming the identity of excipients.

- Fourier-Transform Infrared Spectroscopy (FTIR) and Raman Spectroscopy: These techniques provide a vibrational fingerprint of the molecules, helping to identify the specific polymorph of the API used in the RLD and identify the chemical nature of the excipients.

- X-Ray Powder Diffraction (XRPD): The gold standard for identifying crystalline structures and polymorphs.

- Scanning Electron Microscopy (SEM): Provides high-magnification images of the product’s structure. For Toprol-XL®, SEM would be crucial for visualizing the structure of the controlled-release pellets and their coatings.

- Dissolution Testing: A critical test that measures the rate at which the drug is released from the tablet over time in different media (e.g., mimicking the pH of the stomach and intestine). The dissolution profile of the RLD is the primary target that the generic formulation must match.

By combining the results of these tests, the scientific team can piece together a remarkably detailed picture of the RLD.

Identifying and Quantifying Excipients: The ‘Inactive’ Ingredients That Aren’t

Through deformulation, our team would identify the excipients in Toprol-XL®. They might find things like microcrystalline cellulose (a filler and binder), silicon dioxide (a flow agent), and, most importantly, the polymers used to control the drug’s release, such as ethylcellulose or hydroxypropyl methylcellulose (HPMC).

However, simply identifying the excipients is not enough. The team needs to determine their approximate quantity. This is where the “art” comes in. Regulatory guidelines allow for some flexibility in the types and amounts of excipients used, as long as the final product is bioequivalent. The FDA’s Inactive Ingredient Database (IID) provides information on excipients used in approved drug products and their maximum potency, which serves as a crucial guide [8].

The deformulation report gives the formulators their starting point. They now have a qualitative and semi-quantitative recipe for the RLD. They know the API’s target properties, they know the ingredients used by the innovator, and they have a target dissolution profile to aim for. The pre-formulation gauntlet has been run. Now, the real formulation work can begin.

The Heart of the Matter: Core Formulation Challenges in Our Metoprolol Succinate Case Study

With the strategic groundwork laid, our development team now enters the core of the labyrinth: the formulation laboratory. This is where theory meets practice, and where the true complexity of replicating a sophisticated drug product like Metoprolol Succinate ER comes into sharp focus. The goal is to build a new vehicle—our generic formulation—that arrives at the same destination (bioequivalence) as the innovator’s vehicle, even if it takes a slightly different road to get there. The journey is fraught with three main challenges: mastering the extended-release mechanism, navigating the complexities of excipients, and implementing a modern, proactive development philosophy.

The Extended-Release (ER) Hurdle: Mimicking a Sophisticated Delivery System

The single greatest challenge in developing a generic for Toprol-XL® is replicating its 24-hour extended-release profile. An immediate-release tablet is like a sprinter; it releases its payload all at once. An ER tablet is a marathon runner; it must pace itself perfectly over a long duration. For a highly soluble drug like metoprolol, this is like trying to make a marathon runner, who naturally wants to sprint, maintain a slow, steady jog for 26.2 miles.

Understanding the Innovator’s ER Technology: The Geomatrix™ System

As we discovered during patent analysis, the innovator’s Toprol-XL® uses a multi-particulate system. The drug is loaded onto beads or pellets, which are then coated with a release-controlling polymer. These tiny, independent drug-delivery systems are then compressed into a tablet. This has several advantages: the release is independent of the tablet’s position in the GI tract, and it reduces the risk of “dose dumping”—the catastrophic failure of the ER system leading to a sudden, toxic release of the entire drug dose.

Our generic company cannot simply copy this. It’s protected intellectual property. Therefore, the first major decision is to select an alternative ER technology. The most common and cost-effective alternative for many ER products is a hydrophilic matrix system. In this approach, the API is intimately mixed with a swellable polymer, like hydroxypropyl methylcellulose (HPMC), and compressed into a simple tablet.

Here’s how it works: When the tablet is swallowed, the HPMC on the surface hydrates and swells, forming a viscous gel layer. This gel layer acts as a barrier to drug release. The highly soluble metoprolol at the surface dissolves, but it must diffuse slowly through this tortuous gel layer to be released. As the outer layer erodes, a new layer of the matrix is exposed to water and hydrates, maintaining the gel barrier. The rate of release is controlled by the rate of diffusion through the gel and the rate of tablet erosion [9]. It’s a beautifully simple concept, but incredibly difficult to perfect.

The Challenge of Matching Dissolution Profiles: In Vitro, In Vivo Correlation (IVIVC)

The ultimate goal is bioequivalence, which is measured in vivo (in humans). However, running human clinical trials for every experimental formulation would be prohibitively expensive and time-consuming. Therefore, the lab workhorse is in vitro (in glass) dissolution testing. The team must develop a dissolution method that accurately reflects how the drug will behave in the human body. The holy grail here is to establish an In Vitro-In Vivo Correlation (IVIVC).

An IVIVC is a predictive mathematical model that relates an in vitro property (like the dissolution rate at various time points) to an in vivo response (like the plasma concentration profile, Cmax and AUC) [10]. If a strong IVIVC can be established, the formulators can use the much faster and cheaper dissolution test as a reliable surrogate for human studies during development. They can tweak their hydrophilic matrix formulation, test the dissolution profile, and have high confidence that if they match the RLD’s in vitro profile, they will also match its in vivo performance.

For our metoprolol case, the team would perform hundreds of dissolution tests, varying the pH of the dissolution medium to simulate the stomach (pH ~1.2) and the intestine (pH ~6.8). They would aim to create a formulation whose dissolution curve perfectly overlays the curve of Toprol-XL® across all conditions.

Polymer Science: Selecting the Right Hydrophilic Matrix (e.g., HPMC)

The success of the hydrophilic matrix approach hinges entirely on the polymer. The choice of HPMC is not a simple one. HPMC comes in many different grades, which vary in two key properties:

- Viscosity: Higher viscosity grades form a stronger, more resilient gel layer, slowing down drug release. Lower viscosity grades form a weaker gel, leading to faster release.

- Molecular Weight / Degree of Substitution: These chemical properties also influence the rate of hydration and the gel’s physical characteristics.

Our formulators would need to experiment with different grades and concentrations of HPMC. Too little polymer, or too low a viscosity, and the drug will “dump” out in the first few hours. Too much polymer, or too high a viscosity, and the drug release will be “strangled,” leading to incomplete release over 24 hours and a failed bioequivalence study. They might even blend different grades of HPMC to fine-tune the release profile, creating a more complex and robust system. This empirical, yet systematic, process of experimentation is at the very core of ER formulation development.

The Excipient Enigma: Quality, Variability, and Interaction

While the release-controlling polymer is the hero of the ER formulation, the supporting cast of other excipients is just as critical. The seemingly “inactive” ingredients can have a profound impact on the final product’s quality, stability, and manufacturability. This is the excipient enigma: overlooking these components is a common and costly mistake.

“Up to 40% of Complete Response Letters [CRLs] issued by the FDA for generic drug applications cite deficiencies related to Chemistry, Manufacturing, and Controls (CMC). A significant portion of these are tied to issues with excipient characterization, quality, and their impact on the drug product’s critical quality attributes.”— Based on analyses of FDA data and industry reports [11].

Sourcing and Qualifying Excipients: The Global Supply Chain Puzzle

A generic company might identify microcrystalline cellulose (MCC) as a key filler/binder in their formulation. But MCC is not a single, uniform substance. It’s a product derived from wood pulp, and its properties can vary significantly depending on the manufacturer, the source of the pulp, and even the specific manufacturing batch. One supplier’s MCC might have different particle size, density, and moisture content than another’s.

This variability can wreak havoc. A change in the MCC batch could alter the powder blend’s flowability, leading to tablet weight variation. Or it could affect the tablet’s hardness, which in turn can influence the hydration of the HPMC matrix and alter the drug release profile.

Therefore, our team can’t just order “MCC” from a catalog. They must:

- Screen multiple suppliers: Test MCC from different vendors to see which one gives the desired performance.

- Establish tight specifications: Define the critical material attributes (CMAs) for their chosen MCC—particle size, density, moisture content, etc.—and work with the supplier to ensure they can provide it consistently.

- Qualify the supplier: Audit the supplier’s manufacturing facilities and quality systems to ensure they are reliable.

This process must be repeated for every single excipient in the formulation. It’s a massive undertaking that underscores the importance of a robust global supply chain and quality control system.

Excipient-API Interactions: A Silent Saboteur of Stability

Another hidden danger is the potential for chemical interactions between the API and the excipients. These interactions can degrade the API over time, leading to a loss of potency and the formation of potentially harmful impurities. The product might look perfect on day one but fail stability testing after three months in a bottle.

For example, many APIs have amine groups (like metoprolol) that can react with reducing sugars found in excipients like lactose, in a process called the Maillard reaction. This leads to brownish discoloration and API degradation. Another common issue is interaction with reactive impurities often found in excipients, such as peroxides in povidone, which can oxidize the API.

To mitigate this risk, formulators perform excipient compatibility studies. They create small binary mixtures of the API with each potential excipient and store them under accelerated stability conditions (e.g., high temperature and humidity). They then analyze the mixtures at various time points to check for signs of degradation. This helps them screen out problematic excipients early in the development process, preventing a costly stability failure down the line.

The Impact of Excipient Variability on Critical Quality Attributes (CQAs)

Ultimately, the goal is to control the Critical Quality Attributes (CQAs) of the final product. CQAs are the physical, chemical, biological, or microbiological attributes that must be within an appropriate limit, range, or distribution to ensure the desired product quality [12]. For our Metoprolol ER tablets, the key CQAs would be:

- Assay (Potency): The amount of metoprolol succinate in each tablet.

- Content Uniformity: The consistency of the dosage among tablets.

- Dissolution Profile: The rate of drug release over 24 hours.

- Purity: The level of any impurities or degradation products.

- Hardness and Friability: The physical strength of the tablet.

Every excipient, and every variable in the manufacturing process, can potentially impact these CQAs. The formulator’s job is to understand these relationships so they can control them. This leads us to a more modern and powerful approach to formulation: Quality by Design.

Embracing Quality by Design (QbD) – A Proactive Approach

The traditional approach to formulation was often “quality by testing.” A formulation was developed, and then the final product was tested to see if it met specifications. If it failed, the formulators would go back and try again. This can be an inefficient, trial-and-error process.

Quality by Design (QbD) flips this paradigm. It’s a systematic, proactive approach to development that begins with the end in mind. It emphasizes understanding the product and the process to build quality in from the start, rather than testing for it at the end [12].

As Dr. Evelyn Reed, a fictional Head of Formulation at a leading generic firm, puts it, “QbD transformed us from being cooks following a recipe to being chefs who understand the chemistry of every ingredient. We don’t just hope the cake turns out right; we engineer it to be perfect every time by understanding how the flour’s gluten content and the oven’s temperature fluctuations will affect the final crumb. It’s about control, not chance.”

Defining the Quality Target Product Profile (QTPP)

The QbD journey for our metoprolol project begins with defining the Quality Target Product Profile (QTPP). This is a prospective summary of the quality characteristics of a drug product that ideally will be achieved to ensure the desired quality, taking into account safety and efficacy. It’s the “destination” for our development journey. The QTPP for generic Metoprolol ER would include:

- Dosage form and strength: Tablet, 25 mg, 50 mg, 100 mg, 200 mg.

- Route of administration: Oral.

- Pharmacokinetic profile: Bioequivalent to Toprol-XL® (specific Cmax and AUC targets).

- Release profile: Extended-release over 24 hours, matching the RLD’s dissolution profile.

- Stability: Stable for at least 24 months.

Identifying Critical Material Attributes (CMAs) and Critical Process Parameters (CPPs)

With the QTPP as our guide, we then work backward. What are the key variables that will affect our CQAs? These fall into two categories:

- Critical Material Attributes (CMAs): The physical properties of our raw materials (API and excipients). For our hydrophilic matrix, the CMAs would include the API particle size, the HPMC viscosity, and the MCC particle size and density.

- Critical Process Parameters (CPPs): The key parameters of our manufacturing process. These could include blender speed and time, the force used by the tablet press, and the drying temperature.

The goal is to identify which of these dozens of potential variables are truly critical. Changing a non-critical parameter won’t significantly impact the final product quality. But a small change in a CPP or CMA could push the product out of specification.

Design of Experiments (DoE): Systematically Exploring the Formulation Space

How do we identify these critical parameters and understand their relationships? Through Design of Experiments (DoE). DoE is a powerful statistical tool for planning and conducting experiments efficiently. Instead of changing one factor at a time, DoE allows formulators to vary multiple factors simultaneously in a structured way.

For our metoprolol formulation, the team might design an experiment to study the effect of three key factors on the dissolution CQA:

- HPMC Concentration: (e.g., 20% vs. 30%)

- HPMC Viscosity Grade: (e.g., Low vs. High)

- Tablet Hardness: (e.g., 8 kp vs. 12 kp)

A full factorial DoE would involve testing all possible combinations (2x2x2 = 8 formulations). The results of these experiments are then analyzed to create a mathematical model that describes the relationship between the factors and the response (dissolution rate). This model allows the team to visualize the “formulation space”—a multi-dimensional map showing which combinations of parameters will result in a successful product. They can then identify the optimal operating range, known as the Design Space, where they have high confidence that the product will always meet its CQAs.

By using this QbD approach, our team moves from guesswork to a deep, quantitative understanding of their product. They have not only developed a formulation that works, but they also understand why it works and how to control it, which is invaluable as they prepare to move from the small scale of the R&D lab to the massive scale of commercial manufacturing.

From Lab Bench to Production Scale: The Manufacturing and Scale-Up Odyssey

A perfect formulation on paper, or even one that performs flawlessly in a 1,000-tablet batch in the R&D lab, is still a long way from a commercial success. The next great challenge is the scale-up and manufacturing odyssey: the complex process of translating that small-scale success into a robust, reproducible, and cost-effective process capable of producing millions or even billions of tablets. This is where the physics of powder flow, the mechanics of machinery, and the logistics of technology transfer collide. What works beautifully on the lab bench can, and often does, fail spectacularly at production scale if not managed with foresight and expertise.

Process Development: Taming the Manufacturing Variables

Once the formulation is finalized through the QbD approach, the focus shifts to designing the manufacturing process that will bring it to life. For a solid oral dosage form like our Metoprolol ER tablet, the team must make critical decisions about the manufacturing train and then meticulously control every step within it.

Wet Granulation vs. Direct Compression: A Critical Decision

For most multi-ingredient tablet formulations, the powders cannot simply be mixed and pressed. They often have poor flowability or a tendency to segregate (where lighter particles rise and heavier ones sink), which would lead to tablets with inconsistent dosages (poor content uniformity). To solve this, powders are typically granulated—a process of particle size enlargement. The two most common methods are:

- Wet Granulation (WG): The powder blend is mixed with a liquid binder (a “granulating fluid,” often water or an alcohol solution) to form a wet mass. This mass is then milled, dried, and sized to create uniform granules with excellent flowability and compressibility. WG is a robust but complex, multi-step process involving more equipment and longer processing times.

- Direct Compression (DC): This is the simplest and most cost-effective method. The API and excipients are simply blended together and then compressed directly into tablets. This requires that the ingredients inherently have good flow and compression properties. It’s the ideal process from an efficiency standpoint but is often not feasible for formulations with high drug loads or poorly flowing components.

For our Metoprolol ER hydrophilic matrix tablet, the choice is critical. The HPMC polymer might be gummy and difficult to flow. The drug load is relatively high in the higher-strength tablets. A wet granulation process would likely be chosen to ensure all the ingredients—the API, the HPMC, the filler—are intimately bound together in uniform granules. This ensures that every tablet has the correct proportion of drug and release-controlling polymer, which is essential for consistent dissolution performance. The choice of granulating fluid (e.g., water vs. an ethanol/water mix) would itself become a critical process parameter to study, as it can affect the granule properties and even the hydration of the HPMC.

The Intricacies of Blending, Granulation, and Compression

Each step in the chosen wet granulation process is its own universe of variables that must be controlled.

- Blending: How long should the powders be mixed? What type of blender (e.g., V-blender, bin blender) should be used? What speed? Under-mixing leads to non-uniformity. Over-mixing can, paradoxically, also cause segregation or can break down particles. The goal is to achieve a state of perfect homogeneity, which must be validated with rigorous testing (taking samples from 10+ locations in the blender and testing their potency).

- Granulation: In a high-shear granulator, the impeller speed, chopper speed, and the rate of addition of the granulating fluid are all CPPs. They determine the density and particle size of the resulting granules. These granule properties, in turn, directly impact the tablet’s final hardness and dissolution rate.

- Drying: The granules are typically dried in a fluid bed dryer. The inlet air temperature, airflow rate, and drying time must be precisely controlled to achieve a target moisture content. Over-drying can make the granules brittle and difficult to compress. Under-drying can lead to tablet sticking during compression and long-term stability issues.

- Compression: The final granules are compressed into tablets on a high-speed rotary tablet press. The key CPPs here are the compression force and the press speed. Compression force determines the tablet’s hardness and thickness. For our hydrophilic matrix, hardness is a CQA because it controls how quickly water can penetrate the tablet to form the gel layer. A harder tablet will have a slower release rate. The press speed determines the dwell time (how long the powder is under compression), which can also affect tablet properties.

The Role of Process Analytical Technology (PAT) in Real-Time Monitoring

The traditional way to control these processes was to take a sample at the end of a step (e.g., after drying) and test it in the QC lab. If it failed, the entire batch might have to be discarded. This is inefficient and reactive.

The modern approach, aligned with QbD, is to implement Process Analytical Technology (PAT). PAT involves using online, real-time analytical tools to monitor the process as it happens. For example:

- Near-Infrared (NIR) Spectroscopy: A probe can be inserted directly into the blender to monitor blend uniformity in real-time, telling the operator the exact moment the blend is homogeneous.

- Moisture Sensors: A probe in the fluid bed dryer can monitor the moisture content of the granules continuously, allowing the process to be stopped at the precise target, rather than relying on a fixed time.

- Tablet Hardness Testers: Modern tablet presses can have integrated systems that measure the hardness of tablets as they are being made, and even automatically adjust the compression force to keep the hardness within the target range.

PAT provides a dynamic, real-time understanding of the manufacturing process, allowing for control and adjustment on the fly. This ensures that every batch is made consistently within the validated Design Space, dramatically improving quality and reducing the risk of batch failure [13].

The Scale-Up Challenge: What Works in the Lab Might Fail in the Plant

The process development work is typically done on small, lab-scale equipment (e.g., a 1 kg blender). The next, and often most perilous, step is scale-up: transferring the process to the much larger equipment needed for commercial production (e.g., a 500 kg blender). This is not as simple as multiplying all the parameters by 500. The physics of processes change dramatically with scale.

As John Chen, a veteran process engineering consultant, often remarks, “Scale-up is where the beautiful theories of the lab meet the brutal realities of industrial physics. The laws of thermodynamics and fluid dynamics don’t care about your successful lab batch. You have to respect the change in scale, or it will humble you.”

Geometric Similarity vs. Process Dynamics: A Common Pitfall

A common mistake is to assume that if the production equipment is geometrically similar to the lab equipment (just bigger), the process will behave the same way. This is rarely true.

Consider blending. In a small V-blender, powders mix relatively quickly and efficiently. In a massive production-scale bin blender, the volume is vastly larger, and achieving uniform mixing is much more difficult. Dead spots can form where powder doesn’t move, and the potential for segregation is much higher. The team can’t just run the blender for the same amount of time; they must re-validate the blending time at the new scale.

Similarly, in wet granulation, the way the granulating fluid is sprayed and distributed across a 500 kg powder bed is completely different from in a 1 kg bowl. The drying dynamics in a large fluid bed dryer are also far more complex. The scale-up team must use principles of engineering, such as maintaining constant tip speed in a granulator or ensuring equivalent heat transfer per unit mass in a dryer, to guide the translation of parameters. But ultimately, each step must be re-optimized and re-validated at scale.

Tech Transfer: Ensuring a Seamless Handover from R&D to Manufacturing

Successful scale-up relies on a successful technology transfer. This is the formal process of transferring knowledge, documentation, and responsibility from the R&D team that developed the product to the Manufacturing team that will produce it. A well-executed tech transfer is a collaborative process, not just a case of “throwing the recipe over the wall.”

The tech transfer package is a comprehensive set of documents that includes:

- The final formulation and manufacturing process description.

- The QTPP, CQAs, CMAs, and CPPs identified during development.

- The established Design Space.

- Specifications for all raw materials and the final product.

- Analytical methods for testing the materials and product.

- Validation reports from the lab-scale work.

The manufacturing team needs to be involved early in the process development so they can provide input on the feasibility of the proposed process on their equipment. This collaboration prevents R&D from developing a process that is “perfect” in the lab but impossible or impractical to run at commercial scale.

Validation Batches: The Final Proof of Concept Before Regulatory Submission

The culmination of the scale-up and tech transfer process is the manufacture of the validation batches (also known as pivotal or registration batches). These are typically the first three commercial-scale batches of the product, manufactured in the actual facility and on the actual equipment that will be used for routine production.

These batches serve two critical purposes:

- Process Validation: They prove that the manufacturing process is robust, controlled, and consistently produces a product that meets all of its pre-defined quality attributes (CQAs). Extensive sampling and testing are performed throughout the process and on the final tablets to confirm this.

- Bioequivalence Study Material: The tablets used in the pivotal human bioequivalence (BE) study must be from a batch that is representative of future commercial production. Therefore, the tablets for the BE study are typically taken from one of these validation batches.

Successfully manufacturing three consecutive validation batches that meet all specifications is the final technical hurdle before the company can compile its regulatory submission. It is the ultimate proof that the team has not only mastered the formulation science but has also conquered the immense challenge of bringing that science to life at an industrial scale.

The Regulatory Maze: Proving “Sameness” to the FDA

After years of painstaking work in the lab and the manufacturing plant, our generic Metoprolol ER team has a product they believe is a perfect replica of Toprol-XL®. They have a stable formulation, a robust manufacturing process, and three successful validation batches in hand. Now, they face the final, formidable gatekeeper: the regulatory agency. In the United States, this means submitting an Abbreviated New Drug Application (ANDA) to the FDA. This is not merely a paperwork exercise; it is the construction of a comprehensive scientific and legal argument to prove that their product is safe, effective, and, above all, bioequivalent. Navigating this regulatory maze requires precision, transparency, and a deep understanding of the agency’s expectations.

The Abbreviated New Drug Application (ANDA) Pathway

The ANDA pathway is “abbreviated” because it doesn’t require the generic sponsor to conduct their own independent, large-scale clinical trials to prove safety and efficacy. Instead, the ANDA relies on the FDA’s previous finding that the innovator product (the RLD) is safe and effective. The generic firm’s job is to provide sufficient evidence to prove their product’s “sameness” to the RLD [14].

An ANDA is an enormous and complex document, often running to hundreds of thousands of pages. It is organized into modules, with the most critical being the module on Chemistry, Manufacturing, and Controls (CMC).

Chemistry, Manufacturing, and Controls (CMC): The Backbone of the Submission

The CMC section is the technical core of the ANDA. It is where the company tells the entire story of its product and process. It’s the culmination of all the work described in the previous sections. The CMC section must provide exhaustive detail on:

- Drug Substance (API): Information about the API manufacturer, the synthesis process, its physicochemical characteristics (including polymorphism and particle size), and specifications.

- Drug Product (The Tablet):

- Formulation: A complete list of all components and their quantities.

- Development Story (Pharmaceutical Development Report): This is where the QbD work shines. The company explains why they chose their formulation and process. They describe their risk assessments, their DoE studies, and how they established the Design Space. This demonstrates a deep understanding of the product.

- Manufacturing Process: A detailed, step-by-step description of the manufacturing process, including all equipment and all CPPs.

- Excipient Controls: Justification for the choice and grade of each excipient and the controls placed on them.

- Container Closure System: Details about the bottle, cap, and liner used to package the tablets, and proof that this system protects the product.

- Stability Data: Full stability data from the validation batches, typically for at least 6 months under accelerated conditions (e.g., 40°C/75% RH) and long-term conditions (e.g., 25°C/60% RH).

The CMC section must be a fortress of data, leaving no room for ambiguity. Every claim must be supported by evidence. Any weakness or gap in the CMC data is a primary reason for the FDA to issue a deficiency letter, delaying approval.

The GDUFA Effect: Timelines, Fees, and First-to-File Exclusivity

The generic drug approval process was significantly reshaped by the Generic Drug User Fee Amendments (GDUFA). Enacted in 2012 and subsequently reauthorized, GDUFA allows the FDA to collect fees from generic drug manufacturers to fund the review process. In exchange, the FDA commits to meeting specific performance goals and timelines for reviewing ANDAs [15].

This has created a more predictable, albeit expensive, environment. Companies now know roughly how long a standard or priority review will take. GDUFA also places a premium on getting the submission right the first time. A “first-cycle approval,” where the ANDA is approved without major deficiencies, is the goal for every company. It saves time, money, and gets the product to market faster.

This ties back to the race for first-to-file (FTF) status. The first company to submit a “substantially complete” ANDA containing a Paragraph IV certification (challenging one of the innovator’s patents) is eligible for 180 days of marketing exclusivity. This period can be incredibly lucrative, making the speed and quality of the initial ANDA submission a critical business strategy.

The Bioequivalence (BE) Study: The Moment of Truth

While the CMC section proves the product is well-made and controlled, the bioequivalence (BE) study is the ultimate test that proves it works the same as the RLD. This is the moment of truth where the product’s performance is tested in the human body.

Designing the Pivotal BE Study: Fasting, Fed, and Statistical Analysis

For our Metoprolol ER product, the BE study will be a randomized, single-dose, two-way crossover study. Here’s what that means:

- A group of healthy volunteers (typically 24-72 subjects) is enrolled.

- Randomized: Each subject is randomly assigned to receive either the generic product (the Test, or “T”) or the innovator product (the Reference, or “R”) first.

- Single-Dose: They take one tablet.

- Crossover: After taking the first drug, there is a “washout” period (long enough for the drug to be completely eliminated from their bodies). Then, they “cross over” and receive the other product. This design is powerful because each subject acts as their own control, reducing variability.

Throughout the study, blood samples are drawn from each subject at multiple time points (e.g., before dosing, and then at 1, 2, 4, 6, 8, 10, 12, 16, 24, 36, and 48 hours after dosing). These blood samples are analyzed to determine the concentration of metoprolol in the plasma at each time point.

Navigating Food-Effect Studies: A Common Stumbling Block for ER Drugs

Because Metoprolol ER is an extended-release product, its performance can be affected by the presence of food in the stomach. Food can change the pH of the stomach and the rate at which the tablet empties into the intestine, potentially altering the drug release profile. Therefore, the FDA will almost certainly require two separate BE studies:

- A Fasting Study: Subjects fast overnight before taking the drug.

- A Fed Study: Subjects consume a standardized high-fat, high-calorie breakfast shortly before taking the drug.

The generic product must prove it is bioequivalent to the RLD in both the fed and fasting states. A failure in the fed study is a common reason for BE failure for ER products. For example, the high-fat meal might disrupt the gel layer of our hydrophilic matrix tablet in a way that doesn’t happen with the innovator’s multi-particulate system, leading to “dose dumping” in the fed state. This is a risk that the formulators must have anticipated and designed for.

Interpreting the Results: Cmax, AUC, and the 90% Confidence Interval

From the plasma concentration data, two key pharmacokinetic (PK) parameters are calculated for each subject for both the Test and Reference products:

- C_max: The maximum or peak concentration of the drug in the plasma. This reflects the rate of absorption.

- AUC (Area Under the Curve): The total area under the plasma concentration-time curve. This reflects the total extent of drug absorption.

The statistical analysis then compares the geometric mean of these parameters for the Test product to the Reference product. To be declared bioequivalent, the 90% Confidence Interval (CI) for the ratio of the geometric means (Test/Reference) for both C_max and AUC must fall entirely within the acceptance range of 80.00% to 125.00% [4].

This statistical window is precise and unforgiving. If the 90% CI for C_max is, for example, 79.50% to 110.00%, the study has failed, even though the point estimate might be very close to 100%. If the CI is 95.00% to 126.00%, it has also failed. There is no room for error. A successful BE study is the final piece of evidence needed for the ANDA.

Responding to Regulatory Scrutiny

After an average of 10 months (the GDUFA goal for a standard review), the company will receive a communication from the FDA. In a best-case scenario, it’s an Approval Letter. More commonly, however, it’s a letter outlining deficiencies.

Complete Response Letters (CRLs): Understanding and Addressing Deficiencies

If the FDA finds issues that prevent approval, they will issue a Complete Response Letter (CRL). A CRL details all the deficiencies found during the review. These can range from minor labeling requests to major issues with the CMC data or a failed BE study.

The most dreaded CRLs are those that cite fundamental flaws in the product’s development. For instance:

- “Your proposed manufacturing process lacks sufficient controls for the critical granulation step. The data provided does not ensure consistent granule properties, which could impact the dissolution profile. Please provide additional validation data.”

- “The stability data provided shows an out-of-specification impurity at the 6-month time point. Please identify this impurity and revise your formulation or manufacturing process to control it.”

- “Your product failed to meet the bioequivalence criteria in the fed state study. The 90% CI for Cmax was [data]. This application cannot be approved.”

Receiving a CRL triggers a frantic period of problem-solving. The company must thoroughly investigate the deficiencies, conduct new experiments or studies if necessary, and submit a formal response to the FDA. Each round of review takes time, pushing back the launch date and allowing competitors to gain ground.

The Post-Approval Lifecycle: Maintaining Quality and Compliance

Receiving an approval letter is not the end of the regulatory journey. The company now has a license to manufacture and sell the drug, but it also has a responsibility to maintain its quality and compliance for its entire lifecycle.

This involves:

- Annual Reporting: Submitting annual reports to the FDA summarizing production data and any changes made.

- Change Control: Any change to the formulation, manufacturing process, raw material suppliers, or manufacturing site must be carefully evaluated. Depending on the significance of the change, it may require notifying the FDA or even submitting a formal supplement to the ANDA for prior approval.

- Pharmacovigilance: Monitoring and reporting any adverse events reported by patients using the generic product.

- Inspections: Being subject to routine FDA inspections of the manufacturing facility to ensure ongoing compliance with Current Good Manufacturing Practices (cGMP).

The regulatory maze is a continuous process that demands vigilance, precision, and a commitment to quality that extends far beyond the initial approval. For our generic Metoprolol ER team, a successful navigation of this maze is the final validation of their scientific and strategic excellence.

Post-Mortem and Future Forward: Lessons Learned and Broader Implications

The arduous journey of developing a generic version of Metoprolol Succinate Extended-Release tablets is now complete. Our hypothetical team navigated the patent minefield, conquered the scientific complexities of formulation and scale-up, and successfully traversed the regulatory maze. This singular, focused case study serves as a microcosm of the broader challenges and strategies that define the modern generic pharmaceutical industry. Now is the time to conduct a post-mortem: to distill the key lessons from this specific experience and then look forward to the evolving landscape that awaits the next generation of generic products.

Key Takeaways from the Metoprolol Succinate ER Case Study

If we were to debrief our project team, several core themes would emerge as critical success factors. These are not just technical achievements but strategic imperatives that blend science, business, and regulatory acumen.

The Synergy of Patent Analysis, QbD, and Advanced Analytics

The success of this project was not born from a single breakthrough but from the powerful synergy of three distinct disciplines.

- Proactive Patent Strategy: The project began with a clear-eyed view of the innovator’s patent estate. By using intelligence from platforms like DrugPatentWatch, the team didn’t just see a patent cliff; they saw a specific, navigable path. They understood which technological avenues were blocked (the innovator’s multi-particulate system) and which were open. This “designing around” strategy, established from day one, prevented wasted effort and potential legal battles down the road. It transformed the patent landscape from a barrier into a roadmap.

- Deep Analytical Characterization: The meticulous deformulation of Toprol-XL® and the exhaustive physicochemical characterization of the metoprolol succinate API were the bedrock of the project. The team wasn’t just guessing; they were working from a detailed blueprint. Advanced techniques like XRPD to confirm polymorphism and SEM to visualize the RLD’s structure provided invaluable, actionable data that guided the entire formulation effort.

- Rigorous Quality by Design (QbD) Implementation: QbD was the unifying philosophy. It forced the team to ask “why?” at every step. By defining a QTPP, identifying CQAs, and using DoE to map the Design Space for their hydrophilic matrix system, they built a deep, fundamental understanding of their product. This proactive approach minimized trial-and-error, de-risked the scale-up process, and provided a powerful narrative of control and understanding for the CMC section of the ANDA. They didn’t just find a formulation that worked; they engineered a robust product and process.

The lesson is clear: these three pillars are not sequential steps but are interwoven and interdependent. A winning generic strategy requires them to work in concert.

The Criticality of Excipient Control and Understanding Drug Delivery Mechanisms

The case study hammered home a fundamental truth often overlooked: there are no “inactive” ingredients. The success of the hydrophilic matrix system was entirely dependent on the specific grade, quality, and consistency of the HPMC polymer. The project’s success was equally dependent on controlling the attributes of every other excipient, from the filler to the lubricant.

This underscores the critical importance of a robust supply chain and stringent raw material qualification. A generic company’s quality system is only as strong as its control over its suppliers. The team’s diligence in performing excipient compatibility studies and setting tight in-house specifications prevented stability failures and manufacturing deviations that could have derailed the project.

Furthermore, the core challenge was not just chemistry but physics—the physics of drug delivery. The team had to become experts in diffusion through a hydrated polymer gel. They had to understand how tablet hardness, polymer viscosity, and GI fluid mechanics would interact to produce the desired 24-hour release profile. This highlights that as generic products become more complex, formulation scientists must also be materials scientists and biopharmaceutics experts.

The Evolving Landscape of Generic Formulation

The challenges faced with Metoprolol ER, once considered a complex product, are rapidly becoming the standard. The low-hanging fruit—the simple, immediate-release tablets and capsules—have largely been “genericized.” The future of the industry, and the arena for future growth and competition, lies in products that are significantly more complex.

Complex Generics: The Next Frontier (Injectables, Topicals, Inhalers)

The FDA itself has prioritized and encouraged the development of “complex generics” [16]. These are products that present unique challenges in proving “sameness” and are harder to develop, thus facing less competition. This category includes:

- Long-Acting Injectables and Implants: How do you prove that your microsphere-based injectable, designed to release a drug over three months, is bioequivalent to the RLD? Traditional blood-level studies are often insufficient. It requires sophisticated in vitro release testing and may even require comparative clinical endpoint studies.

- Topical Products (Creams, Ointments, Gels): For drugs that act locally on the skin, there is no blood level to measure. Proving bioequivalence requires demonstrating equivalent drug delivery into the skin, using advanced techniques like in vitro permeation testing (IVPT) through human skin samples. The physical properties of the cream—its viscosity, globule size, and “feel”—also become critical quality attributes.

- Inhaled and Nasal Products (MDIs, DPIs): For an asthma inhaler, the generic must deliver the same amount of drug with the same particle size distribution to the same regions of the lung as the innovator product. This requires highly specialized testing of the device itself and the aerosol plume it generates. Proving BE is a massive aerodynamic and engineering challenge, not just a formulation one.

These products will require an even greater investment in specialized analytical capabilities, novel bioequivalence approaches, and multi-disciplinary expertise.

The Rise of Biosimilars: A New Paradigm of “Sameness”

If complex small-molecule generics are a step up in difficulty, biosimilars are a quantum leap. Biosimilars are the “generic” versions of large-molecule biologic drugs, which are produced in living cell systems rather than through chemical synthesis. Products like monoclonal antibodies for cancer or autoimmune diseases are immensely complex, and it is impossible to create an identical copy.

The regulatory pathway for biosimilars, therefore, is not based on “sameness” but on demonstrating that the product is “highly similar” to the reference product with “no clinically meaningful differences” in terms of safety, purity, and potency [17]. This requires a massive analytical undertaking to compare the complex structures of the proteins, followed by PK studies, and often, a confirmatory clinical efficacy trial. Formulation is still critical—ensuring the delicate protein remains stable and active—but it is part of a much larger and more data-intensive development paradigm. The world of biosimilars represents the ultimate formulation and manufacturing challenge.

The Impact of Artificial Intelligence and Machine Learning in Formulation Development

How will companies tackle these ever-increasing complexities? One of the most promising avenues is the integration of Artificial Intelligence (AI) and Machine Learning (ML). The vast amounts of data generated during a QbD-based development process are ripe for AI-driven analysis.

Imagine these scenarios:

- Predictive Formulation: An ML algorithm is trained on thousands of past formulation experiments. A formulator inputs the desired QTPP and the API’s physicochemical properties, and the algorithm proposes a handful of high-probability starting formulations, dramatically reducing the time spent on initial screening.

- Intelligent Process Control: AI systems connected to PAT sensors could monitor a manufacturing process in real-time and make predictive adjustments to CPPs to prevent deviations before they happen, ensuring every batch stays perfectly within its Design Space.

- BE Prediction: Algorithms could analyze in vitro dissolution data and other formulation properties to predict the probability of passing a BE study, allowing companies to better assess risk before committing to an expensive clinical trial.

While still in its early stages, the application of AI/ML has the potential to revolutionize generic drug development, making it faster, more efficient, and more predictable. It could be the key to unlocking the next frontier of complex generics and making these critical medicines more accessible to patients worldwide.

Conclusion: Beyond Replication to Strategic Innovation

The journey through the development of a generic Metoprolol Succinate Extended-Release tablet reveals a profound truth about the pharmaceutical industry: creating a “copy” is, in its own way, as scientifically demanding and strategically complex as creating an original. The process is a testament to the power of reverse engineering, a relentless pursuit of sameness that demands a mastery of chemistry, material science, engineering, and regulatory law. It is far more than simple replication; it is a discipline of strategic innovation within defined constraints.

We’ve seen that success is not accidental. It is built upon a foundation of deep patent intelligence, exhaustive pre-formulation science, and a steadfast commitment to the principles of Quality by Design. It requires taming the wild variables of manufacturing and scale-up, and meticulously constructing a fortress of data to satisfy the exacting standards of regulatory bodies. The challenges are immense—from mimicking sophisticated drug delivery systems to controlling the subtle variability of every ingredient—but the rewards are transformative. Every successful generic product that reaches the market eases the burden on patients and strengthens the sustainability of our healthcare systems.

Looking forward, the terrain is only becoming more challenging. The era of simple generics is waning, giving way to the complex frontier of long-acting injectables, intricate topicals, and the monumental task of developing biosimilars. To succeed in this new landscape, generic companies must evolve. They must become even more sophisticated in their analytical capabilities, more creative in their formulation strategies, and more willing to embrace new technologies like artificial intelligence to navigate the mounting complexity.

Ultimately, the story of generic drug development is a story of resilience and ingenuity. It is about turning the scientific and regulatory labyrinth into a solvable puzzle. For the business leaders, scientists, and professionals in this field, the path forward is clear: continue to push the boundaries of science and strategy, not just to replicate the medicines of yesterday, but to ensure affordable access to the vital therapies of today and tomorrow.

Key Takeaways

- Strategy Begins with Patents: A successful generic strategy starts long before the lab, with a deep analysis of the innovator’s patent estate. Using tools like DrugPatentWatch to understand the full scope of patent protection and identify “design around” opportunities is a critical first step.

- Bioequivalence is the Non-Negotiable Goal: The core technical challenge is achieving bioequivalence—matching the rate (C_max) and extent (AUC) of drug absorption of the innovator product. This requires meticulous reverse engineering and formulation development.

- Quality by Design (QbD) is the Modern Standard: Proactively building quality into a product via QbD—by defining a QTPP, identifying CQAs, and mapping a Design Space through DoE—is more efficient and effective than traditional trial-and-error methods. It de-risks development, scale-up, and regulatory submission.

- Excipients are Not ‘Inactive’: The choice, quality, and variability of excipients have a profound impact on the final product’s performance, manufacturability, and stability. Rigorous excipient qualification and control are paramount.

- Scale-Up is a Unique Challenge: A successful lab-scale formulation does not guarantee success at commercial scale. The physics of manufacturing processes change with scale, requiring dedicated re-optimization and validation to ensure a robust and reproducible process.

- The Future is Complex: The generic industry is moving towards more complex products (e.g., long-acting injectables, topicals, inhalers) and biosimilars. Success in this new era will require greater investment in specialized technology, novel BE approaches, and advanced analytical science.

Frequently Asked Questions (FAQ)

1. What is the biggest mistake companies make when developing a challenging extended-release (ER) generic like the one in the case study?

The most common and costly mistake is underestimating the interplay between the formulation and the manufacturing process. A team might develop a “perfect” formulation in the lab that achieves the target dissolution profile. However, they may not have fully considered how the stresses of large-scale manufacturing—such as the high shear in a large granulator or the compression forces of a high-speed tablet press—will affect the integrity of their release-controlling mechanism (e.g., the HPMC gel matrix). This can lead to unexpected changes in the dissolution profile in the validation batches, failed BE studies, and costly delays. A robust QbD approach, where manufacturing parameters (CPPs) are studied alongside formulation variables (CMAs) from the beginning, is the best way to mitigate this risk.

2. How does a generic company decide whether to challenge an innovator’s patent (a Paragraph IV filing) versus waiting for it to expire?

This is a high-stakes business decision that balances risk and reward. The primary reward is the potential for 180 days of market exclusivity for being the “first to file.” This can be worth hundreds of millions of dollars. The risks, however, are substantial. Patent litigation is incredibly expensive, can take years, and there is no guarantee of winning. The decision involves a multi-faceted analysis:

- Legal Assessment: How strong is the innovator’s patent? Are there clear grounds for invalidity or non-infringement?

- Technical Feasibility: Can we actually develop a non-infringing formulation? Or is the patent so broad that it’s impossible to “design around”?

- Commercial Landscape: How large is the market for the drug? How many other generic companies are likely to also file a challenge? If multiple companies challenge, the value of being first is diluted.

- Financial Resources: Does the company have the capital to sustain a prolonged and expensive legal battle?Often, a company will only pursue a Paragraph IV filing if the legal case is strong and the commercial prize is exceptionally large.

3. The article mentions the FDA’s Inactive Ingredient Database (IID). How critical is this tool, and what are its limitations?

The IID is an absolutely critical tool for generic formulators. It provides a list of excipients used in FDA-approved products and, most importantly, the maximum potency (amount per dosage unit) for a particular route of administration (e.g., oral). This gives formulators a “safe harbor” of sorts. If they use a common excipient at a level at or below what’s listed in the IID for an oral product, they generally don’t need to conduct additional safety studies for that excipient. Its limitations, however, are that it doesn’t provide information on the grade or function of the excipient in the innovator product, nor does it specify the total daily intake. Furthermore, if a formulator needs to use a novel excipient or a known excipient at a level higher than what is listed in the IID, they face a much higher regulatory burden to prove its safety, which can significantly complicate and delay the development program.

4. Can a generic product technically be “better” than the brand-name drug?

This is a fascinating and nuanced question. From a regulatory standpoint, the goal is “sameness” (bioequivalence), not superiority. A generic product that is significantly more bioavailable than the RLD would fail the BE criteria and would not be approved as a generic. However, a generic company could theoretically make improvements in other areas. For example, they might develop a formulation using different excipients that results in a more stable product with a longer shelf life. They might use a manufacturing process that produces more elegant, less friable tablets. Or they might use an excipient that is less likely to cause issues for patients with certain sensitivities (e.g., formulating without lactose). While these improvements may be real, they cannot be marketed as claims of superiority. The product is simply approved as being therapeutically equivalent.

5. How is the rise of AI and machine learning actually changing the day-to-day work of a formulation scientist?

AI and ML are shifting the role of a formulation scientist from a hands-on experimenter to more of a data strategist and systems manager. Instead of spending weeks manually preparing dozens of trial-and-error formulations, a scientist might spend their time:

- Curating Data: Ensuring that historical experimental data is clean, structured, and ready to be fed into an ML model.

- Designing Smart Experiments: Using AI suggestions to design smaller, more information-rich DoE studies that can more efficiently map a design space.

- Interpreting Models: Analyzing the output of predictive models to gain deeper insights into complex API-excipient interactions that might not be intuitive.

- Focusing on the Edges: Using their expert knowledge to investigate the “edge cases” or unexpected results that an algorithm might flag, rather than just confirming the obvious.In essence, AI is becoming a powerful assistant that handles the computational heavy lifting and pattern recognition, freeing up the human scientist to focus on higher-level problem-solving, creative strategy, and the deep scientific understanding that models alone cannot provide.

References

[1] Association for Accessible Medicines. (2023). 2023 Generic Drug & Biosimilars Access & Savings in the U.S. Report. https://accessiblemeds.org/resources/reports/2023-generic-drug-biosimilars-access-savings-us-report

[2] IQVIA Institute for Human Data Science. (2023). The Use of Medicines in the U.S. 2023. https://www.iqvia.com/insights/the-iqvia-institute/reports/the-use-of-medicines-in-the-us-2023

[3] U.S. Food and Drug Administration. (2019). Hatch-Waxman Amendments. https://www.fda.gov/newsevents/testimony/ucm115033.htm

[4] U.S. Food and Drug Administration. Code of Federal Regulations Title 21, Part 320 (21CFR320). Bioavailability and Bioequivalence Requirements. https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?CFRPart=320

[5] Sandberg, A., et al. (1988). Pharmacokinetic and pharmacodynamic properties of a new controlled-release formulation of metoprolol: a comparison with a conventional tablet. European Journal of Clinical Pharmacology, 33(Suppl), S9-S14.

[6] Amidon, G. L., Lennernäs, H., Shah, V. P., & Crison, J. R. (1995). A theoretical basis for a biopharmaceutic drug classification: the correlation of in vitro drug product dissolution and in vivo bioavailability. Pharmaceutical research, 12(3), 413-420.

[7] Bauer, J., et al. (2001). Ritonavir: an extraordinary example of conformational polymorphism. Pharmaceutical research, 18(6), 859-866.

[8] U.S. Food and Drug Administration. Inactive Ingredient Database. https://www.accessdata.fda.gov/scripts/cder/iig/index.cfm