Introduction: Beyond Bioequivalence – The Next Competitive Frontier for Generics

For decades, the generic drug industry has been defined by a singular, relentless pursuit: achieving bioequivalence at the lowest possible cost. The term “generic drug” itself often conjures an image of a simple, no-frills copy of a brand-name medication—a perception that, while true on the surface, belies the immense complexity of the journey from patent expiration to pharmacy shelf. This journey is a veritable gauntlet of sophisticated scientific reverse-engineering, labyrinthine regulatory approvals, and high-stakes legal warfare that has fundamentally reshaped the economics of modern healthcare. In the United States alone, generic drugs account for a staggering nine out of every ten prescriptions filled, making this industry the bedrock of affordable medicine for millions.

The competitive landscape has always been brutal, governed by a simple and unforgiving rule: price is king. The moment a blockbuster drug loses its patent protection, a flood of generic competitors enters the market, triggering a precipitous price cascade. The entry of just a second generic manufacturer can slash the drug’s price to nearly half that of the brand, with prices continuing to plummet as more players join the fray. This dynamic has created a “race to the bottom,” where success is measured in fractions of a cent and margins are perpetually squeezed.

But what if this paradigm is incomplete? What if the relentless focus on price has obscured a more powerful, more durable source of competitive advantage?

A parallel narrative has been unfolding, one that is moving from the periphery of corporate social responsibility reports to the core of strategic business planning. The pharmaceutical industry, for all its life-saving innovations, carries a heavy environmental burden. Its manufacturing processes are notoriously resource-intensive, with some estimates suggesting its carbon emissions are up to 55% higher than the automotive sector. The industry is infamous for its high E-Factor (the ratio of waste to product), which can range from 25 to over 100, meaning for every kilogram of active pharmaceutical ingredient (API) produced, more than 100 kilograms of waste can be generated.5 This waste isn’t just an environmental problem; it’s a direct and significant component of the cost of goods sold (COGS).

This is where the two narratives converge, creating a powerful inflection point for the generic drug industry. The principles of Green Chemistry—a framework for designing chemical products and processes that reduce or eliminate hazardous substances, minimize waste, and conserve energy—are no longer just an ethical ideal. They are a strategic imperative.

This report will argue that in the hyper-competitive generics market, sustainable manufacturing through the application of green chemistry is the next great competitive frontier. It offers a pathway to fundamentally re-engineer cost structures, mitigate regulatory and supply chain risks, and build a more resilient, profitable, and reputable business. We will deconstruct the entire generic drug lifecycle, overlaying it with the principles of green chemistry to reveal the critical points of intervention. We will explore the revolutionary technologies—from designer enzymes to continuous flow reactors—that are making green chemistry more accessible and powerful than ever. And we will make the irrefutable business case that for a generic drug company, the greenest process is, ultimately, the most profitable process. The question is no longer if a company should invest in green chemistry, but how quickly it can master its principles to lead the future of sustainable medicine.

Part 1: The Foundational Pillars

Deconstructing Green Chemistry: The 12 Principles as a Business Blueprint

At its core, green chemistry is a proactive design philosophy. Coined in the early 1990s and formalized into a set of 12 guiding principles by Paul Anastas and John Warner, it represents a fundamental shift from managing pollution after it has been created to preventing it at the molecular level.7 For the business professional in the pharmaceutical industry, these principles should not be viewed as a list of environmental constraints, but rather as a powerful blueprint for operational excellence, risk mitigation, and cost reduction. Each principle is a lever that, when pulled, can generate cascading benefits across the entire manufacturing value chain.

The 12 principles, first published in 1998, provide a comprehensive framework for chemists and engineers to design or improve materials, products, and processes to be more sustainable.10 Let’s explore these principles not as abstract ideals, but as strategic business tools.

1. Prevention: “It is better to prevent waste than to treat or clean up waste after it has been created”.10 This is the cornerstone of green chemistry and the most important principle, from which all others flow. In business terms, this translates to “waste is a cost.” Every kilogram of byproduct, every liter of spent solvent, represents purchased raw materials that were not converted into valuable product. The pharmaceutical industry has historically generated staggering amounts of waste. This is often measured using metrics like the

E-Factor (kg waste / kg product) or Process Mass Intensity (PMI), which is the total mass of all materials (water, solvents, reagents, etc.) used to produce one kilogram of API. For many drugs, the PMI can exceed 100, meaning over 100 kg of materials are consumed to make just 1 kg of the final medicine. Applying green chemistry principles has been shown to achieve dramatic reductions, sometimes as much as tenfold. Preventing waste at the source eliminates the need for costly “end-of-pipe” treatments, hazardous waste disposal, and the associated regulatory burdens.

2. Atom Economy: “Synthetic methods should be designed to maximize the incorporation of all materials used in the process into the final product”. Developed by Barry Trost, this principle moves beyond traditional yield calculations. A reaction might have a 95% yield, but if the desired product only constitutes 50% of the mass of all the atoms in the reactants, the atom economy is poor. This metric directly targets the efficiency of a chemical transformation. From a business perspective, high atom economy means you are paying for raw materials that end up in your product, not in your waste stream. It is a direct measure of resource efficiency.14

3. Less Hazardous Chemical Syntheses: “Wherever practicable, synthetic methods should be designed to use and generate substances that possess little or no toxicity to human health and the environment”. This principle focuses on mitigating intrinsic risk. Using toxic or hazardous reagents introduces significant operational costs and liabilities, including the need for specialized handling equipment, robust containment systems, extensive personal protective equipment (PPE) for workers, and higher insurance premiums. By designing syntheses that use safer chemicals, companies can reduce these direct costs and, more importantly, minimize the risk of costly workplace accidents or environmental releases.

4. Designing Safer Chemicals: “Chemical products should be designed to affect their desired function while minimizing their toxicity”. While generic manufacturers are bound to replicate an existing API, this principle has profound implications for the design of the overall process. It encourages a deep understanding of the toxicology of not just the final product, but also of all intermediates, byproducts, and reagents involved. This knowledge allows for the design of processes that avoid the formation of highly toxic or mutagenic impurities, which can be a major hurdle in gaining regulatory approval.

5. Safer Solvents and Auxiliaries: “The use of auxiliary substances (e.g., solvents, separation agents, etc.) should be made unnecessary wherever possible and innocuous when used”. Solvents are the lifeblood of pharmaceutical manufacturing, but they are also one of the largest contributors to waste and environmental impact, often accounting for the majority of the mass in a non-aqueous process.5 This principle drives the search for benign alternatives like water or bio-derived solvents, or for processes that require no solvent at all. As we will explore later, eliminating hazardous solvents like chlorinated hydrocarbons (e.g., dichloromethane) or ethers (e.g., THF) can lead to massive cost savings in procurement, recovery, and disposal.

6. Design for Energy Efficiency: “Energy requirements of chemical processes should be recognized for their environmental and economic impacts and should be minimized. If possible, synthetic methods should be conducted at ambient temperature and pressure”. Every reaction that requires extreme heating, cooling (cryogenics), or high pressure consumes significant energy, which translates directly to high utility bills. Designing processes that operate under mild conditions is a direct path to reducing a manufacturing plant’s operational costs and carbon footprint.

7. Use of Renewable Feedstocks: “A raw material or feedstock should be renewable rather than depleting whenever technically and economically practicable”. The vast majority of pharmaceutical starting materials are derived from petroleum, a finite and price-volatile resource.17 This principle encourages a strategic shift toward bio-based feedstocks derived from sources like sugars, plant oils, or algae. This is not just an environmental consideration; it is a long-term supply chain security strategy, insulating a company from the geopolitical and economic volatility of the fossil fuel market.

8. Reduce Derivatives: “Unnecessary derivatization (use of blocking groups, protection/deprotection, temporary modification) should be minimized or avoided if possible, because such steps require additional reagents and can generate waste”. In complex organic synthesis, chemists often have to “protect” one part of a molecule while reacting another, and then “deprotect” it later. Each of these steps adds time, cost, reagents, and waste to a process. Streamlining a synthesis to avoid these temporary modifications leads to a more elegant, efficient, and cost-effective process. As we will see, technologies like biocatalysis are particularly adept at achieving this.

9. Catalysis: “Catalytic reagents (as selective as possible) are superior to stoichiometric reagents”. This is one of the most powerful principles for driving efficiency. Stoichiometric reagents are consumed in a reaction, often in large quantities, and end up as waste. Catalysts, by contrast, are used in very small amounts to accelerate a reaction and can, in theory, be recovered and reused indefinitely. The shift from stoichiometric reagents to highly selective metal catalysts or biocatalysts can reduce waste by orders of magnitude and is a hallmark of modern, green process chemistry.

10. Design for Degradation: “Chemical products should be designed so that at the end of their function they break down into innocuous degradation products and do not persist in the environment”. This principle addresses the end-of-life impact of chemicals. While the API’s structure is fixed, this principle applies to all other chemicals used in the process, such as solvents, reagents, and processing aids. Choosing materials that are readily biodegradable reduces the long-term environmental liability and the cost associated with treating persistent pollutants in wastewater streams.

11. Real-Time Analysis for Pollution Prevention: “Analytical methodologies need to be further developed to allow for real-time, in-process monitoring and control prior to the formation of hazardous substances”. This principle champions the use of Process Analytical Technology (PAT). By monitoring a reaction in real-time, operators can ensure it stays within optimal parameters, maximizing yield and preventing “runaway” reactions or the formation of unwanted byproducts that would become waste. PAT is a key component of the FDA’s Quality by Design (QbD) initiative, linking green chemistry directly to modern regulatory expectations.

12. Inherently Safer Chemistry for Accident Prevention: “Substances and the form of a substance used in a chemical process should be chosen to minimize the potential for chemical accidents, including releases, explosions, and fires”. This principle is a synthesis of many others. By choosing less toxic materials (Principle 3), safer solvents (Principle 5), and running reactions at ambient conditions (Principle 6), the inherent safety of a process is dramatically improved. This reduces risk to workers, the surrounding community, and the business itself.

These principles are not a disconnected checklist but a deeply interconnected system. For instance, adopting a highly selective catalyst (Principle 9) often allows a reaction to run at room temperature (Principle 6) in a safer solvent like water (Principle 5), which in turn generates far less waste (Principle 1) and improves atom economy (Principle 2). This cascading effect is what makes green chemistry such a powerful strategic tool. A single, well-chosen process improvement can trigger a domino effect of cost savings and risk reduction across the board.

The Generic Drug Lifecycle: A Strategic Overlay for Green Chemistry

To truly leverage the power of green chemistry, it’s not enough to understand the principles; one must know precisely when and where to apply them within the complex and high-pressure timeline of generic drug development. The lifecycle of a generic drug, from initial opportunity assessment to market launch, presents a series of critical inflection points. Integrating green chemistry at the right stage is the difference between a marginal improvement and a fundamental competitive advantage.

The modern generic industry was born from the Drug Price Competition and Patent Term Restoration Act of 1984, better known as the Hatch-Waxman Act. This landmark legislation created the Abbreviated New Drug Application (ANDA) pathway, which allows a generic manufacturer to gain FDA approval without repeating the costly and lengthy clinical trials required for the original brand-name drug. Instead, the generic firm must prove its product is bioequivalent—that it delivers the same amount of active ingredient to the bloodstream over the same period of time as the innovator’s product, known as the Reference Listed Drug (RLD).20 This places immense focus on the Chemistry, Manufacturing, and Controls (CMC) section of the ANDA, making the API synthesis and formulation processes the scientific and regulatory heart of generic development.

Let’s walk through the typical generic lifecycle and identify the strategic windows for green chemistry integration.

Stage 1: Market and Patent Analysis

Every generic journey begins with strategic product selection. Companies meticulously scan the pharmaceutical landscape to identify brand-name drugs with patents nearing their expiration date, often referred to as the “patent cliff”. This is a sophisticated exercise in risk management, involving a deep analysis of market size, potential competition, and the complexity of the brand’s patent portfolio, or “patent thicket”.

At this stage, companies rely heavily on competitive intelligence platforms. Services like DrugPatentWatch are indispensable, providing critical data on patent expiration dates, potential patent term extensions, regulatory exclusivities, and ongoing patent litigation.1 This intelligence allows a company to decide which products represent the most attractive commercial opportunities. While green chemistry doesn’t play a direct role here, the decisions made at this stage set the context for all subsequent development. A high-volume, blockbuster drug with a complex synthesis is a prime candidate for a green chemistry-driven cost reduction strategy.

Stage 2: Formulation and Process Development (The Green Chemistry Epicenter)

Once a target drug is selected, the scientific race begins. This stage involves two parallel streams: reverse-engineering the brand’s formulation (a process known as de-formulation) and, most critically, developing a novel, robust, and scalable synthetic route for the active pharmaceutical ingredient (API).2

This is the single most important stage for integrating green chemistry.

The R&D team is tasked with creating a chemical process that can produce the API at commercial scale, meeting stringent purity requirements, consistently and cost-effectively. The choices made here—the starting materials, the solvents, the catalysts, the number of steps—will be largely locked in for the commercial life of the product.

A critical and often-overlooked reality is the concept of regulatory “lock-in.” As a drug progresses through development, the regulatory burden for making changes to the API synthesis process increases dramatically. The FDA’s International Conference on Harmonization (ICH) Q11 guidance makes it clear that while process changes are expected in early development, the process is ideally “locked” before the production of materials for pivotal bioequivalence studies or late-stage trials. Any significant change after this point, especially post-ANDA submission, requires extensive validation, comparability studies, and regulatory re-filing, which can cause costly delays and jeopardize a product’s launch timeline.23

This creates a powerful strategic tension. The pressure to get to market quickly can tempt teams to choose the fastest-to-develop synthetic route, even if it’s inefficient and wasteful (a “dirty” process). However, a company that falls into this trap will be saddled with higher manufacturing costs for years. In contrast, a company that invests slightly more time and resources upfront to design an elegant, efficient, and green process will build a durable cost advantage into its product from day one. This front-loading of green chemistry is not a luxury; it is a fundamental strategic decision that transforms process R&D from a simple support function into a primary engine of long-term value creation.

Stage 3: Analytical Method Development

In parallel with process development, chemists must create and validate robust analytical methods to test the API and finished product for identity, purity, quality, and stability. This ensures that every batch produced meets the required specifications. Here too, green chemistry principles can be applied. The field of “green analytical chemistry” focuses on developing methods that minimize or eliminate the use of hazardous reagents and solvents (e.g., replacing acetonitrile in HPLC with safer alternatives), reduce energy consumption, and generate less waste. While the economic impact may be smaller than in bulk manufacturing, it contributes to overall operational efficiency and worker safety.

Stage 4: Bioequivalence (BE) Studies

This is the pivotal clinical stage where the generic drug is tested in human volunteers to prove it is bioequivalent to the RLD. While green chemistry has no direct role in the execution of these studies, the quality of the API produced by the manufacturing process is paramount. A process that is poorly controlled or produces inconsistent impurity profiles can lead to failed BE studies, which are incredibly expensive and time-consuming to repeat. A well-designed green process, with its inherent focus on control, selectivity, and waste reduction, often yields a cleaner product with a more consistent purity profile. This de-risks the BE study phase by ensuring the clinical trial material is of the highest and most reproducible quality.

Stage 5: Scale-Up and Technology Transfer

Successfully transferring a process from the small-scale R&D lab to a large-scale commercial manufacturing plant is one of the most challenging steps in pharmaceutical development.2 Reactions that work perfectly in a 1-liter flask can behave very differently in a 1,000-liter reactor. Green technologies offer significant advantages here. For example, a process designed using continuous flow chemistry scales up by simply running the system for a longer duration, not by building a larger, more complex, and potentially more dangerous reactor. This makes tech transfer smoother, faster, and less capital-intensive.

Stage 6: ANDA Submission and FDA Review

The culmination of the development process is the submission of the ANDA to the FDA. This massive dossier contains all the CMC data, BE study results, proposed labeling, and patent certifications. A well-designed green process can strengthen the CMC section significantly. It demonstrates a high degree of process understanding and control, which aligns perfectly with the FDA’s Quality by Design (QbD) philosophy. A process with a lower PMI, fewer hazardous materials, and a cleaner impurity profile presents a lower overall risk profile to the regulator, potentially smoothing the path to a first-cycle approval—a powerful competitive weapon in the race to market.

By strategically overlaying the principles of green chemistry onto this lifecycle, it becomes clear that sustainability is not an afterthought. It is a tool to be wielded at every stage to reduce cost, mitigate risk, and build a more efficient and resilient path to market.

Part 2: The Green Toolbox: Technologies Revolutionizing API Synthesis

The theoretical appeal of green chemistry is compelling, but its practical implementation hinges on a toolbox of innovative technologies that are transforming how chemists approach the synthesis of complex molecules. For the generic drug industry, mastering these tools is key to unlocking the promised benefits of efficiency, cost reduction, and sustainability. Three technologies, in particular, stand out as pillars of the green chemistry revolution: biocatalysis, continuous flow chemistry, and the development of novel green solvents.

The Power of Nature’s Catalysts: Biocatalysis in Action

For decades, organic synthesis has relied heavily on classical chemical catalysts, many of which involve rare, expensive, and often toxic heavy metals. Biocatalysis offers a powerful and elegant alternative by harnessing nature’s own high-performance catalysts: enzymes. At its core, biocatalysis is the use of enzymes—or whole microbial cells containing them—to perform chemical transformations on organic compounds.

What makes enzymes so compelling from a green chemistry perspective is their extraordinary performance under incredibly mild conditions. Unlike many traditional chemical reactions that require high temperatures, high pressures, and harsh solvents, enzymatic reactions typically proceed in water at neutral pH and ambient temperature. This directly addresses multiple green chemistry principles simultaneously, including energy efficiency (Principle 6), use of safer solvents (Principle 5), and inherently safer chemistry (Principle 12).

Perhaps the most significant advantage of enzymes is their “exquisite chemo-, regio-, and stereoselectivity”. Many pharmaceutical ingredients are chiral molecules, meaning they exist in two mirror-image forms (enantiomers), only one of which is therapeutically active. Producing the correct enantiomer in high purity is a major challenge in pharmaceutical synthesis. Enzymes, having evolved over billions of years to perform highly specific tasks, can often distinguish between these mirror images with near-perfect precision. This allows for the direct synthesis of the desired chiral amine or alcohol, for example, with very high enantiomeric excess, avoiding wasteful resolution steps that have a maximum theoretical yield of 50%.

For a long time, biocatalysis was considered a “niche tool,” limited by the chance discovery of a natural enzyme that happened to work on a synthetic, non-natural drug intermediate. This has been completely upended by the advent of enabling technologies like gene mining and, most importantly, directed evolution. Pioneered by Nobel laureate Frances Arnold, directed evolution allows scientists to take a naturally occurring enzyme with some desired activity and rapidly “evolve” it in the lab through iterative rounds of mutation (often via gene shuffling) and high-throughput screening.26 This revolutionary technique allows for the creation of “designer enzymes” that are custom-built, or “fit-for-purpose,” for a specific industrial process. Scientists can now engineer enzymes with enhanced stability in organic solvents, higher activity at elevated temperatures, or improved selectivity for a specific man-made substrate.

This has fundamentally changed the risk-reward calculation for the pharmaceutical industry. R&D teams no longer have to hope to find the right enzyme; they can now predictably engineer one. This transforms biocatalysis from a scientific curiosity into a robust, reliable, and strategically vital technology platform. Companies can now proactively design a biocatalytic route into their synthesis plan, confident that they can develop an enzyme to meet the required performance criteria. This accessibility is further enhanced by the availability of commercial enzyme screening kits and development services, which allow even smaller generic companies to tap into the power of this technology. By replacing multi-step chemical sequences with a single, highly selective enzymatic step, biocatalysis can dramatically shorten synthetic routes, reduce waste, and build quality and efficiency into a process from the very beginning.

Rethinking the Reaction Vessel: The Rise of Continuous Flow Chemistry

For over a century, chemical manufacturing has been dominated by the paradigm of batch processing: ingredients are loaded into a large tank (a reactor), mixed, reacted, and then the product is drained out before the next batch begins. Continuous flow chemistry represents a fundamental and disruptive shift from this model. Instead of using large, static tanks, flow chemistry performs reactions by pumping reagents through a network of small tubes, coils, or microreactors in a continuous, uninterrupted stream.25 This seemingly simple change has profound implications for safety, efficiency, and scalability.

The advantages of continuous flow chemistry align almost perfectly with the goals of green chemistry:

- Unparalleled Safety: Perhaps the most dramatic benefit is the improvement in process safety. Traditional batch reactors can hold thousands of liters of flammable solvents and reactive chemicals. A thermal runaway or an uncontrolled exothermic reaction in such a vessel can be catastrophic. In a flow system, the total volume of the reaction mixture at any given moment is minuscule—often just a few milliliters or liters. The high surface-area-to-volume ratio of the narrow tubing allows for extremely efficient heat transfer, meaning any heat generated by the reaction is dissipated almost instantly. This allows chemists to safely handle highly reactive intermediates or perform highly energetic reactions that would be far too dangerous to attempt on a large scale in a batch reactor.

- Precision and Control: Flow systems offer a level of process control that is simply unattainable in a large, poorly mixed batch reactor. Parameters like temperature, pressure, residence time, and reagent stoichiometry can be controlled with surgical precision, leading to more consistent product quality, higher yields, and significantly fewer impurities. This enhanced control means less batch-to-batch variability and a more robust and reliable manufacturing process.

- Process Intensification and Integration: Flow chemistry is a key enabler of process intensification. Because the equipment is modular, it’s possible to link multiple reaction, workup, and purification steps together in a single, seamless, and automated production line.25 This can turn a multi-day, multi-vessel batch process into a single continuous operation that takes only hours, dramatically reducing the manufacturing footprint, capital investment, and manual labor required.

- Simplified Scalability: Scaling up a batch process is a major engineering challenge, often requiring a complete redesign of the reactor and process parameters. In flow chemistry, scaling up is often as simple as running the system for a longer period of time or by “numbering up”—running multiple identical reactors in parallel. This makes the transition from the R&D lab to commercial production significantly faster, cheaper, and less risky.

The transformative potential of this technology was powerfully demonstrated in the synthesis of a key building block for the vital antibiotic tazobactam. Researchers at Pfizer and the National University of Singapore replaced a hazardous and inefficient batch process with a three-step continuous flow synthesis that used water as a solvent. The new method eliminated dangerous intermediates, dramatically enhanced safety, and ensured a more stable and reliable supply chain for this critical medicine.

For the generic industry, continuous flow chemistry is more than just a greener way to manufacture. It is a strategic capability that opens the door to entirely new and more efficient synthetic routes that were previously considered off-limits. By enabling the use of more aggressive but highly effective chemistries, it can dramatically shorten synthetic sequences, leading to step-change reductions in PMI and manufacturing cost. As generic APIs become increasingly complex, the companies that master flow chemistry will possess a core competency that provides a decisive and sustainable competitive edge.

The Solvent Revolution: Moving Beyond Hazardous Chemicals

If there is one single class of materials that defines the environmental footprint of pharmaceutical manufacturing, it is solvents. They are used in nearly every step of a process—for dissolving reactants, facilitating reactions, extracting and purifying products, and cleaning equipment. It is not uncommon for solvents to account for 80-90% of the total mass of all non-water materials in a typical API synthesis, making them the single largest contributor to the industry’s notoriously high E-Factors and PMIs.5 Many of the workhorse solvents of traditional organic chemistry—such as chlorinated solvents (dichloromethane, chloroform), ethers (THF, dioxane), and aromatic hydrocarbons (toluene, benzene)—are toxic, flammable, environmentally persistent, and subject to increasingly stringent regulatory controls.32

The fifth principle of green chemistry—to use safer solvents or make them unnecessary—is therefore a critical leverage point for holistic process improvement. The choice of solvent is a foundational design decision that creates a cascade of consequences affecting everything from reaction efficiency and energy consumption to worker safety and waste disposal costs.

The “solvent revolution” involves a multi-pronged approach:

- Solvent Minimization and Replacement: The first and best option is to design processes that use less solvent or no solvent at all (neat reactions). When a solvent is necessary, the goal is to replace hazardous ones with greener alternatives. Industry consortia like the ACS GCIPR have developed widely used solvent selection guides, which rank common solvents based on a composite score of their environmental, health, and safety impacts. These guides steer chemists away from “undesirable” or “problematic” solvents and towards “recommended” or “preferred” options.

- Water: The Ultimate Green Solvent: From a green chemistry perspective, water is the ideal solvent. It is non-toxic, non-flammable, cheap, and abundant. Its main challenge is the poor solubility of many nonpolar organic molecules. However, when processes can be designed to run in water, the benefits are enormous. A powerful example is Takeda Pharmaceuticals’ second-generation process for the API TAK-954. By re-engineering the synthesis to be almost entirely water-based, they were able to reduce organic solvent consumption by a staggering 94% and increase the overall yield from 35% to 56%.

- Supercritical Fluids: Supercritical carbon dioxide (scCO2) is another attractive green solvent. When carbon dioxide is heated and pressurized above its critical point, it enters a state where it has properties of both a liquid and a gas. It is an excellent solvent for many nonpolar compounds, and its key advantage is that it can be returned to a gaseous state simply by releasing the pressure, leaving behind pure product with no solvent residue. It is non-toxic, non-flammable, and its use does not contribute to net greenhouse gas emissions if sourced as a byproduct from other industrial processes. It is widely used for extraction and for controlling crystallization.

- Bio-derived Solvents and Novel Systems: An active area of research is the development of solvents derived from renewable biomass. Solvents like 2-methyltetrahydrofuran (2-MeTHF), derived from plant sugars, are gaining popularity as greener replacements for traditional ethers like THF. Other bio-derived solvents like limonene (from citrus peels) and p-cymene (from pine trees) have been shown to be effective and even superior to conventional solvents in certain applications. More exotic systems like Ionic Liquids (ILs) and Deep Eutectic Solvents (DESs)—essentially salts that are liquid at room temperature—offer unique solvating properties that can enable new chemistries, although their own lifecycle and potential toxicity must be carefully assessed.6

For a generic drug manufacturer, a solvent selection guide is not just an environmental, health, and safety (EHS) document; it is a strategic financial planning tool. The decision to design a process around a “preferred” green solvent versus a “problematic” red-listed one can have a multi-million dollar impact on the product’s lifetime profitability by avoiding the immense costs associated with specialized handling, energy-intensive recovery, and hazardous waste disposal.

Case Study Deep Dive 1: Pfizer’s Sertraline (Zoloft®) – A Greener Blockbuster

Perhaps no single case study better illustrates the profound, real-world impact of applying green chemistry principles than Pfizer’s revolutionary redesign of the manufacturing process for sertraline, the active ingredient in the blockbuster antidepressant Zoloft®. This effort, which earned Pfizer a prestigious U.S. Presidential Green Chemistry Challenge Award in 2002, serves as a masterclass in how rethinking a chemical synthesis can lead to staggering improvements in efficiency, safety, and environmental performance, all while boosting the bottom line.

The original commercial process for sertraline was a complex, multi-step synthesis that was effective but relied on a host of problematic chemicals and generated significant waste. Recognizing the opportunity for improvement, Pfizer’s process chemistry team undertook a meticulous, principle-by-principle re-evaluation of the entire route.

The breakthrough was the development of what they termed the “combined” process. This innovation managed to streamline a cumbersome three-step sequence from the original synthesis into a single, elegant, and highly efficient step conducted in just one solvent: ethanol.16 Ethanol, a relatively benign and easily handled solvent, replaced a cocktail of four hazardous solvents used in the original process: methylene chloride, tetrahydrofuran (THF), toluene, and hexane. This change alone eliminated the need for the complex and energy-intensive distillation and recovery operations associated with this toxic quartet.

The most significant single improvement came from redesigning the imine formation step. The original process used titanium tetrachloride (TiCl4), a highly corrosive and water-sensitive reagent that generated a massive amount of solid titanium dioxide waste upon quenching. The new process, driven by clever use of solubility differences in ethanol, eliminated the need for TiCl4 entirely. The impact of this single change was monumental, eliminating approximately 310,000 pounds of TiCl4 usage per year. The downstream effect was the prevention of 220,000 pounds of 50% sodium hydroxide waste, 330,000 pounds of 35% hydrochloric acid waste, and a staggering 970,000 pounds of solid titanium dioxide waste annually.

The table below provides a stark, quantitative comparison of the old versus the new process, translating abstract chemical changes into concrete business and environmental metrics.

Table 1: Pfizer’s Sertraline Process Redesign – A Green Chemistry Transformation

| Process Aspect | Original Process (Key Reagents & Solvents) | “Combined” Green Process (Key Reagents & Solvents) | Quantifiable Improvement |

| Key Solvents | Methylene Chloride, Tetrahydrofuran (THF), Toluene, Hexane | Ethanol (single solvent for the entire sequence) | Elimination of four hazardous solvents and their associated recovery/disposal costs. |

| Imine Formation Reagent | Titanium Tetrachloride (TiCl4) | None (driven by reaction conditions in ethanol) | Elimination of ~310,000 lbs/year of TiCl4. |

| Waste Generation | Large volumes of TiCl4-derived waste streams | Minimal waste from the combined step | Elimination of ~1.8 million lbs/year of total hazardous materials, including ~970,000 lbs/year of solid TiO2 waste. |

| Overall Yield | X | 2X | Overall product yield was doubled. |

| Raw Material Use | Standard quantities of tetralone, monomethylamine, mandelic acid | Reduced quantities | Raw material use was cut by 20–60% for key inputs. |

| Process Complexity | Three separate steps for imine formation, reduction, and resolution | A single, streamlined “one-pot” step | Dramatically reduced processing time, energy use, and plant capacity requirements. |

The sertraline redesign is more than just a successful science experiment; it is a landmark business case. It proves that green chemistry is not about making compromises. Pfizer didn’t just create a “less bad” process; they created a better process in every conceivable way. It was safer for workers, gentler on the environment, used fewer raw materials, and, critically, it doubled the overall product yield. The final process achieved an E-Factor of 8, a remarkable figure for a complex pharmaceutical synthesis and a testament to the power of this approach. For any generic drug executive, the message from this case study is irrefutable: investing in green chemistry is investing in a more efficient, more robust, and ultimately more profitable manufacturing operation.

Case Study Deep Dive 2: The Atorvastatin Intermediate – Engineering Enzymes for Success

If the sertraline story highlights the power of elegant chemical process design, the development of a green manufacturing route for a key intermediate of atorvastatin (Lipitor®) showcases the revolutionary impact of modern biotechnology. This case study, which earned Codexis a Presidential Green Chemistry Challenge Award in 2006, demonstrates how biocatalysis, supercharged by directed evolution, can create processes that are not only environmentally superior but also chemically superior to their traditional counterparts.

Atorvastatin, the active ingredient in the world’s first drug to exceed $10 billion in annual sales, is a complex chiral molecule. The synthesis of its key chiral building block, a hydroxynitrile (HN) compound, was a significant challenge.29 Traditional commercial processes were classic examples of “brute force” chemistry. They often involved resolutions that capped yields at 50%, used hazardous reagents like hydrogen bromide, and required harsh, heated alkaline conditions to force the final cyanation step. These conditions inevitably generated extensive byproducts, necessitating a difficult and yield-sapping high-vacuum fractional distillation to purify the final product.29

Codexis, in partnership with the drug’s manufacturer, took a radically different, “green-by-design” approach. They envisioned a process that would leverage the precision of enzymes to build the molecule correctly from the start, avoiding the waste and inefficiency of the chemical route. The result was an elegant two-step, three-enzyme biocatalytic process that operates almost entirely in water at neutral pH and ambient temperature.27

- Step 1: Asymmetric Reduction. The first step uses two enzymes, a ketoreductase (KRED) and a glucose dehydrogenase (GDH) for cofactor recycling, to reduce a starting chloroketone. The KRED enzyme performs the key transformation with near-perfect stereoselectivity, producing the desired (S)-chlorohydrin intermediate with an enantiomeric excess greater than 99.5%.

- Step 2: Biocatalytic Cyanation. The second step uses a third enzyme, a halohydrin dehalogenase (HHDH), to catalyze the replacement of the chlorine atom with a cyanide group. This reaction is performed under neutral pH, a feat impossible with traditional chemistry, which requires alkaline conditions to activate the cyanide nucleophile. This mild approach avoids the base-sensitive decomposition of the starting material and product, leading to a much cleaner reaction.

However, there was a major hurdle: the natural, “wild-type” enzymes were not up to the task. Their activity and stability under industrial conditions were far too low to be economically viable. The natural HHDH, in particular, was so poor that the process was essentially dead on arrival.

This is where directed evolution became the key that unlocked the entire process. Using their proprietary gene shuffling technologies, Codexis scientists put the enzymes through an accelerated evolution process in the lab. They created vast libraries of mutated enzyme variants and screened them for improved performance. The results were nothing short of spectacular. The productivity of the KRED reduction reaction was improved by approximately 100-fold. The HHDH enzyme, which was the critical bottleneck, saw its volumetric productivity improved by an astonishing 4,000-fold compared to the wild-type enzyme.

This bio-engineering feat transformed an economically non-viable process into a commercial success. The final green process eliminated the need for hazardous reagents and cryogenic conditions, used less solvent, required fewer pieces of processing equipment, and dramatically simplified purification to a simple extraction. The overall E-Factor for the process was calculated to be 5.8 (excluding process water), a massive improvement over typical pharmaceutical processes and a direct result of the high selectivity and efficiency of the engineered enzymes.

This case study demonstrates a critical point for the modern generic industry. Green chemistry powered by biotechnology is not about finding a “less bad” way to make a molecule. It’s about finding a smarter way. The biocatalytic route to the atorvastatin intermediate achieves a level of chemical precision that traditional methods simply cannot match. By building quality and selectivity in at the molecular level, it de-risks the entire manufacturing process, reducing the chance of generating problematic impurities that could delay or derail an ANDA approval. It is a powerful example of how investing in cutting-edge green technology can yield a process that is superior on every metric: environmental, chemical, and economic.

Part 3: The Strategic Imperative: Translating Green Chemistry into Market Advantage

While the scientific elegance and environmental benefits of green chemistry are clear, for the leaders of a generic pharmaceutical company, the ultimate question is always: “What is the impact on the bottom line?” The strategic imperative for adopting green chemistry lies in its ability to be translated into tangible, defensible market advantage. This is achieved through a combination of direct economic gains, navigating an increasingly complex regulatory environment, and leveraging industry-wide collaboration to accelerate innovation.

The Economics of Green: Quantifying the Bottom-Line Impact

Adopting green chemistry is not an act of corporate charity; it is one of the most powerful strategies available for improving a company’s financial performance. The economic benefits are central drivers of its adoption, as a greener process is very often a more profitable one. These benefits can be broken down into direct cost savings and more indirect, but equally important, value drivers.

Direct Cost Savings

The most immediate and quantifiable benefits of green chemistry are direct reductions in operational expenditures (OpEx):

- Reduced Waste Disposal Costs: This is the most obvious gain. The pharmaceutical industry’s high waste output comes with a hefty price tag. The global production of APIs is estimated to generate around 10 billion kilograms of waste annually, with a staggering disposal cost of approximately $20 billion. Every kilogram of waste prevented by a greener process—whether through higher atom economy, solvent recycling, or the use of catalysts—is a direct saving on hazardous waste treatment and disposal fees.13

- Higher Yields and Process Efficiency: Green chemistry principles like catalysis and reducing derivatives lead to fewer synthetic steps and higher overall yields.13 Higher yields mean that less raw material (feedstock) is required to produce the same amount of final product, directly lowering raw material costs. Fewer process steps mean faster manufacturing cycles, which can increase the overall throughput and capacity of an existing plant without new capital expenditure.

- Lower Energy Consumption: Designing reactions to run at ambient temperature and pressure, a core tenet of green chemistry, directly reduces a facility’s energy consumption and utility bills. Eliminating energy-intensive steps like high-vacuum distillations or cryogenic cooling can lead to significant savings.

- Reduced Raw Material Costs: Beyond just yield improvements, green chemistry can lower costs by enabling the use of cheaper, more abundant catalysts (e.g., replacing precious metals like palladium with earth-abundant iron or nickel) or by designing processes that use less expensive starting materials.39

Indirect Economic Benefits and Risk Mitigation

Beyond the direct line items on a P&L statement, green chemistry creates value by reducing risk and enhancing corporate reputation:

- Enhanced Worker and Environmental Safety: Using less toxic materials and running processes under milder conditions significantly reduces the risk of fires, explosions, or accidental chemical releases. This translates into lower costs for specialized safety equipment (PPE), fewer lost workdays due to accidents, and potentially lower insurance premiums. It also mitigates the immense financial and reputational risk of a major environmental incident.

- Improved Competitiveness and Corporate Reputation: In an era of increasing focus on Environmental, Social, and Governance (ESG) criteria, a strong sustainability record is a competitive advantage.33 It can attract ESG-focused investors, top-tier talent who want to work for responsible companies, and favorable terms from large healthcare purchasers and pharmacy benefit managers (PBMs) who are themselves under pressure to green their supply chains. One study found that a single-point increase in a pharmaceutical company’s reputation score could lead to a 3.33% increase in sales.

- Supply Chain Resilience: Shifting from petroleum-based feedstocks to renewable, bio-based ones (Principle 7) can insulate a company from the price shocks and geopolitical instability associated with the fossil fuel market, leading to a more predictable and resilient supply chain.

The economic case is often understated because many companies fail to account for the significant value of risk reduction. A traditional ROI calculation might compare the capital cost of a new continuous flow reactor against the projected savings in solvent costs. However, this misses the multi-million-dollar value of not having a plant shut down for a safety violation, or not having a product launch delayed because a key reagent was suddenly banned by regulators. Furthermore, the process intensification enabled by green technologies like flow chemistry allows companies to produce more product in a smaller manufacturing footprint, representing a massive improvement in capital asset optimization.13 Financial leaders need to adopt a more sophisticated, lifecycle-based model for evaluating these investments, framing them not just as cost-reduction projects, but as strategic investments in operational resilience and long-term profitability.

The Regulatory Maze: Navigating FDA and EMA Expectations

The global regulatory landscape for pharmaceuticals is a complex and constantly evolving maze. While regulators like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have not, for the most part, issued explicit mandates to use green chemistry, their policies and strategic priorities are creating powerful indirect incentives that are pushing the industry in a greener direction. For a generic company, understanding and anticipating these regulatory trends is crucial for long-term success.

The FDA: Quality by Design as an Implicit Endorsement

The FDA’s approach is subtle but powerful. The agency’s primary focus is on ensuring drug safety, efficacy, and quality. It achieves this through a framework known as Quality by Design (QbD), which encourages a deep, science-based understanding of the manufacturing process. QbD emphasizes that quality cannot be tested into a product; it must be built into it from the beginning.

This philosophy aligns perfectly with the principles of green chemistry. A green process, by its very nature, is often a more controlled, more efficient, and better-understood process.

- ICH Q11 Guidance: The FDA’s adoption of the International Conference on Harmonization’s Q11 guideline on the development and manufacture of APIs is a key driver. As previously discussed, this guidance establishes a high regulatory bar for making significant changes to a manufacturing process late in development. This creates a strong incentive for companies to invest in developing the best possible process—which is often the greenest process—from the very beginning, rather than trying to patch an inefficient one later.

- Process Analytical Technology (PAT): The FDA actively encourages the use of PAT to monitor and control manufacturing in real-time. This aligns directly with Principle 11 of green chemistry and leads to processes with less variability, fewer out-of-spec batches, and less waste.

While the FDA may not use the words “green chemistry” in its regulations, its emphasis on process robustness, control, and modern manufacturing technology implicitly rewards the outcomes that green chemistry delivers.

The EMA: An Explicit Push Towards Greener Medicines

The European Medicines Agency has been more explicit in its focus on sustainability. The Pharmaceutical Strategy for Europe, adopted in 2020, clearly states a core objective is to support the development of “high quality, safe, effective and greener medicines”. This strategic priority is being translated into concrete regulatory requirements.

- Environmental Risk Assessment (ERA): The EMA requires a formal ERA to be submitted as part of a marketing authorization application. This assessment evaluates the potential risks of the medicinal product to the environment. A significantly revised and more stringent ERA guideline is set to become effective in September 2024, signaling a deepening focus on the environmental lifecycle of drugs. This requirement forces companies to consider the environmental fate and impact of their products, a key aspect of green chemistry’s lifecycle thinking.45

- Balancing Sustainability and Supply: European regulators are also grappling with the potential conflict between stricter environmental rules and the need for a secure drug supply. There are concerns that imposing heavy environmental burdens could make manufacturing in the EU less competitive, potentially exacerbating medicine shortages. This has led to calls for a “balanced and coherent regulatory framework” that promotes sustainability without crippling the industry—a dynamic that savvy companies can navigate by proactively adopting cost-effective green technologies.

The regulatory environment is clearly shifting. The environmental impact of a drug’s manufacturing process is evolving from an external concern into a core component of its regulatory profile. In the near future, a generic drug application that relies on an antiquated, high-waste process may face tougher scrutiny from regulators, especially when cleaner, greener alternatives are well-established. A poor ERA or a demonstrably inefficient process could become a source of regulatory delay. This means that a company’s regulatory affairs department must become as fluent in the language of green chemistry as its process chemists, ready to defend their manufacturing choices not just on quality, but on stewardship as well.

Industry in Motion: The Role of the ACS Green Chemistry Institute Pharmaceutical Roundtable

Recognizing that many of the foundational challenges of green chemistry are too large and complex for any single company to solve alone, the pharmaceutical industry has embraced a powerful model of pre-competitive collaboration. The most prominent example of this is the American Chemical Society (ACS) Green Chemistry Institute Pharmaceutical Roundtable (GCIPR).5

Founded in the early 2000s by leaders from companies like Pfizer and Eli Lilly, the GCIPR brings together dozens of major pharmaceutical companies and their suppliers with a shared mission: to catalyze the innovation and integration of green chemistry and engineering across the industry. The Roundtable operates on a simple but profound premise: by pooling resources to solve common, fundamental scientific problems, all members can benefit from a more advanced technological platform, which they can then use to compete more effectively in the marketplace.

The impact of the GCIPR has been substantial and multifaceted:

- Funding Foundational Research: The Roundtable’s flagship initiative is its grant program, which has invested over $3.5 million since 2007 to support academic research into areas of critical unmet need.49 In its first decade alone, the program funded 28 research projects that resulted in 73 peer-reviewed publications, advancing the entire field. The research targets are highly strategic, focusing on what the industry calls “dream reactions”—transformations that, if solved, would have a massive impact. The 2024 grant program, for example, targets challenges like finding alternatives to hazardous halogenated solvents, developing greener methods for complex peptide and oligonucleotide synthesis, and creating data science tools to accelerate green process design.40

- Developing Practical Tools: The GCIPR is not just an academic funding body; it creates practical tools that chemists can use every day. It has been instrumental in developing and promoting tools like standardized solvent selection guides, reagent guides, and streamlined life-cycle assessment methodologies that help chemists make greener choices during process development.

- Driving Metrics and Benchmarking: An old management adage states, “you can’t manage what you don’t measure”. The Roundtable has been a major force in developing and standardizing green chemistry metrics. It championed the adoption of Process Mass Intensity (PMI) as a more holistic measure of waste than E-Factor and has been a key forum for proposing and debating new concepts like the Green Aspiration Level (GAL), which aims to create a standardized benchmark for assessing the “greenness” of a process relative to its inherent complexity.12

The existence and success of the GCIPR represent a mature and forward-thinking approach by the pharmaceutical industry. It acknowledges that a “rising tide lifts all boats.” By de-risking and funding foundational R&D, the Roundtable accelerates the pace of innovation for the entire sector. For generic companies, which may have more constrained R&D budgets than their brand-name counterparts, the publicly available breakthroughs and tools generated by these collaborations are an invaluable source of cutting-edge, de-risked green technology that can be immediately applied to their own development pipelines.

Part 4: The Path Forward: Challenges and the Future of Sustainable Generics

Despite the compelling business case and the availability of powerful new technologies, the transition to a fully sustainable, green-by-design generic drug industry is not without its obstacles. The path forward requires a clear-eyed understanding of the remaining barriers to adoption, as well as a visionary embrace of the next wave of disruptive technologies that promise to make green chemistry the undisputed standard for pharmaceutical manufacturing.

Barriers to Adoption: Why Isn’t Everyone Green Yet?

If green chemistry is so beneficial, why hasn’t it been universally adopted? The reality is that significant economic, regulatory, and cultural barriers remain, particularly within the fast-moving, cost-sensitive generics sector. A 2017 study that benchmarked green chemistry adoption across the global pharmaceutical supply chain found that while interest is high, implementation lags, especially among generic and API manufacturers.

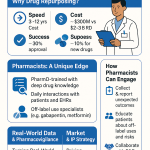

A study of the global pharmaceutical supply chain found that while 35% of generic and API manufacturers have a cross-functional team to lead green chemistry efforts, a staggering 81% have no publicly stated commitment to green chemistry, and 43% do not use any green chemistry metrics to track their performance.

The key barriers include:

- Economic and Financial Hurdles: This remains the number one obstacle. Implementing green chemistry can require significant upfront capital investment in new technologies like continuous flow reactors or specialized biocatalysis equipment. For an existing, marketed product, the cost of developing a new green process and, crucially, re-validating and re-filing it with regulatory agencies can be immense. The potential long-term savings must be substantial enough to justify this upfront cost and risk, a calculation that can be difficult to make, especially for lower-margin products.24

- Regulatory and Time Pressure: According to industry representatives, the top two barriers to adoption are regulatory risk and the intense time pressure to deliver new drugs. The generic drug development timeline is a sprint to beat the patent cliff and secure a favorable market position. In this high-pressure environment, the perceived risk of a novel green process causing a delay in filing or approval often outweighs the potential long-term benefits. The path of least resistance is often to stick with a known, albeit inefficient, traditional chemical route.

- Technical and Scalability Challenges: A green process that works elegantly on the milligram scale in an R&D lab may not be robust or economical when scaled up to the multi-kilogram or ton scale required for commercial manufacturing.2 Issues like catalyst separation, product isolation from aqueous media, or maintaining enzyme stability can become major technical hurdles at industrial scale.

- Infrastructure and Supply Chain Gaps: The ecosystem for green chemistry is still maturing. A lack of reliable, large-scale commercial suppliers for novel green solvents, specialized enzymes, or bio-based feedstocks can be a significant practical barrier to implementation. A company cannot build a manufacturing process around a reagent that it cannot source consistently and cost-effectively.

- Organizational Inertia and Misaligned Incentives: Perhaps the most insidious barrier is cultural. Pharmaceutical companies are large, complex organizations, and the inertia of “the way we’ve always done it” can be powerful. This is often compounded by a misalignment of incentives. The process development R&D team is typically measured on speed to filing, while the manufacturing division is measured on long-term COGS. An R&D team might choose a “dirty” process because it’s faster to develop, successfully meeting their primary metric while shifting the long-term cost burden of waste and inefficiency onto a different part of the organization. Overcoming this requires a fundamental shift in corporate strategy, implementing cross-functional teams and lifecycle-based metrics that make the long-term costs of a process visible to the chemists at the moment of design.

The Next Wave: AI, Machine Learning, and the Future of Synthesis

While the challenges are real, a new wave of technology is poised to dramatically lower these barriers and accelerate the adoption of green chemistry. The convergence of artificial intelligence (AI), machine learning (ML), and automation promises to revolutionize how pharmaceutical processes are designed, optimized, and executed.14

Generative AI and machine learning are moving from the realm of science fiction to practical application in the chemistry lab. Their potential impact is immense:

- Accelerated Process Design and Optimization: Instead of relying on chemists’ intuition and time-consuming trial-and-error experimentation, AI algorithms can analyze vast datasets of known chemical reactions to predict the outcomes of new ones. They can propose novel, highly efficient synthetic routes that a human chemist might never have considered.53 By simulating thousands of reaction conditions virtually, AI can identify the optimal parameters for maximizing yield and minimizing waste before a single experiment is run in the lab, saving enormous amounts of time, resources, and money.

- Discovery of Novel Green Materials: AI can be tasked with designing new molecules with specific properties. This can be used to discover novel green solvents, biodegradable reagents, or highly efficient catalysts that are custom-built for a specific reaction.14 AstraZeneca is already using a machine learning model to accurately predict where a specific chemical reaction will occur on a complex molecule, a task that streamlines development and allows for more sustainable planning.

- Smarter Biocatalysis: Machine learning is supercharging the field of directed evolution. By analyzing the genetic sequences and performance data of enzyme variants, ML models can learn the complex relationship between an enzyme’s structure and its function. This allows them to predict which mutations are most likely to lead to desired improvements in activity or stability, dramatically accelerating the engineering of “fit-for-purpose” biocatalysts.26

The true revolution will come from the integration of these digital tools with advanced manufacturing hardware. One can envision a future paradigm of “autonomous drug synthesis.” In this model, an AI platform designs a novel, green-by-design API synthesis. This digital recipe is then automatically translated into instructions for a modular, robotic continuous flow chemistry system. Real-time PAT sensors continuously monitor the reaction, feeding data back to the AI, which then optimizes the process on the fly by adjusting flow rates, temperatures, and concentrations to maintain peak performance.

This vision of a “pharma-factory-in-a-box” could fundamentally transform the industry. It would dramatically compress development timelines, reduce the need for massive, centralized manufacturing plants, and enable a future of decentralized, on-demand production of essential medicines. For the generic industry, which thrives on speed and efficiency, this AI-powered future represents the ultimate realization of the goals of green chemistry.

Conclusion: From Cost Center to Value Driver – Securing a Sustainable Future in Generics

The landscape of the generic pharmaceutical industry is undergoing a tectonic shift. The traditional business model, built solely on the foundation of being the low-cost provider through rapid imitation, is facing the dual pressures of unsustainable price erosion and increasing scrutiny of its environmental impact. In this new era, clinging to the old ways is not a strategy for success; it is a recipe for obsolescence.

This report has argued that green chemistry has evolved far beyond its origins as a niche environmental movement. It is now a core strategic discipline that offers a clear and actionable path to building a more profitable, resilient, and competitive generic drug business. The 12 principles are not a set of restrictive rules, but a powerful framework for innovation and operational excellence. By preventing waste, maximizing efficiency, and designing for safety, green chemistry directly attacks the largest drivers of manufacturing cost.

The technological barriers are falling rapidly. The “green toolbox”—powered by the precision of biocatalysis, the safety and control of continuous flow chemistry, and the intelligence of AI—has made sustainable manufacturing more accessible and economically viable than ever before. Landmark case studies like Pfizer’s sertraline and the atorvastatin intermediate provide irrefutable proof that the greenest process is often the most elegant, efficient, and profitable process.

Simultaneously, the market and regulatory environments are aligning to reward sustainability. Regulators are increasingly looking at the entire lifecycle of a drug, and investors are channeling capital towards companies with strong ESG credentials. In this context, a commitment to green chemistry is no longer a “cost center” to be minimized, but a “value driver” that enhances reputation, mitigates risk, and attracts investment.

Of course, significant challenges to adoption remain. Overcoming the hurdles of upfront investment, regulatory inertia, and organizational culture will require visionary leadership and a strategic commitment from the highest levels of a company. It demands a shift in mindset, where process R&D is recognized not as a mere support function for filing an ANDA, but as the primary engine for creating long-term, durable competitive advantage.

The conclusion is inescapable. For the generic drug manufacturer looking to thrive in the 21st century, the question is no longer if they should invest in green chemistry, but how deeply and how quickly they can embed its principles into the very DNA of their organization. Those who lead this green revolution will not only contribute to a healthier planet; they will secure their own sustainable future at the forefront of the pharmaceutical industry.

Key Takeaways

- Green Chemistry as a Core Business Strategy: For the generic drug industry, green chemistry is no longer a peripheral CSR activity but a central driver of competitive advantage. In a market defined by intense price erosion, it offers a path to structurally lower manufacturing costs, providing a more durable advantage than price cuts.

- Front-Load Green Chemistry in Development: The most critical window for applying green chemistry is during the initial API process development stage. Due to regulatory “lock-in,” early decisions on synthetic routes have irreversible long-term economic and environmental consequences. Investing time upfront to design a green process yields benefits for the entire commercial life of the product.

- Leverage the “Green Toolbox”: Modern technologies have made green chemistry highly practical. Biocatalysis, supercharged by directed evolution, allows for the creation of “designer enzymes” that offer unparalleled selectivity. Continuous flow chemistry enhances safety and control, enabling chemistries that are too dangerous for traditional batch reactors. Green solvents drastically reduce waste and operational risk.

- Quantifiable Economic Benefits are Massive: The ROI of green chemistry extends far beyond direct cost savings (waste, energy, raw materials). It includes significant value from risk mitigation (avoiding accidents and regulatory delays), enhanced corporate reputation (attracting ESG investors), and improved asset optimization (process intensification).

- Regulatory Tailwinds are Growing: While not always explicit, regulatory bodies like the FDA (via its QbD and PAT initiatives) and the EMA (via its mandatory Environmental Risk Assessments) are creating powerful incentives for sustainable manufacturing. A green process is increasingly seen as a lower-risk, higher-quality process.

- Collaboration Accelerates Innovation: Pre-competitive collaborations, exemplified by the ACS Green Chemistry Institute Pharmaceutical Roundtable, are crucial. By pooling resources to solve fundamental challenges, the entire industry benefits from a more advanced, publicly available technological platform.

- The Future is AI-Driven and Autonomous: The convergence of AI, machine learning, and automated continuous flow systems will create a new paradigm of “autonomous drug synthesis.” This will dramatically compress development timelines and further enhance the efficiency and sustainability of pharmaceutical manufacturing.

Frequently Asked Questions (FAQ)

1. How can a smaller generic company with a limited R&D budget justify the upfront investment in green chemistry technologies like continuous flow or biocatalysis?

This is a critical question of scale and strategy. While the initial capital expenditure for a full-scale continuous flow skid or a comprehensive biocatalysis program can seem daunting, the entry points are more accessible than ever. Companies can start small by:

- Targeting High-Impact Products: Focus initial efforts on high-volume or high-margin products where the long-term savings from a greener process will provide the fastest and most significant ROI.

- Leveraging External Partnerships: Instead of building an in-house biocatalysis lab from scratch, companies can partner with specialized firms (like Codexis) that offer enzyme screening kits and contract development services. This provides access to cutting-edge technology on a fee-for-service basis, lowering the initial barrier.

- Starting with Lab-Scale Flow Systems: Implementing small, modular flow reactors in the R&D lab allows chemists to develop expertise and demonstrate proof-of-concept for greener, more efficient routes without a massive capital outlay. The success of these lab-scale projects can then be used to build a strong business case for investment in pilot-scale or commercial-scale equipment.

- Focusing on “Low-Hanging Fruit”: Not all green chemistry requires expensive equipment. Significant savings can be realized simply by systematically replacing hazardous solvents with recommended green alternatives or by optimizing existing reactions to improve yield and reduce waste, which primarily requires intellectual investment from the chemistry team.

2. Does redesigning a process for an already-marketed generic drug to make it “greener” trigger a complex and risky regulatory re-filing with the FDA?

Yes, it can, and this is a significant barrier. Any fundamental change to the approved manufacturing process for an API, including changes to the synthetic route, solvents, or catalysts that could affect the final product’s impurity profile, requires the submission of a “Prior Approval Supplement” (PAS) to the FDA. The agency must review and approve this supplement before the drug made by the new process can be distributed. This process can be time-consuming and costly, involving new validation batches and extensive comparability data.

However, the risk can be managed. The FDA’s QbD and PAT initiatives encourage a deep understanding of the process. If a company can demonstrate through robust data that the new green process is more controlled and consistently produces an API with an identical or even cleaner impurity profile than the original process, the path to approval can be smoother. The key is to frame the change not just as an environmental improvement but as a quality improvement that leads to a more robust and reliable manufacturing operation, which is a language regulators understand and appreciate.

3. With the rise of green chemistry, will the price of generic drugs increase for consumers due to higher R&D and technology costs?

This is a common misconception. The fundamental economic driver of green chemistry is cost reduction, not cost increase.14 While there may be an upfront investment, the entire philosophy is aimed at creating more efficient processes that use fewer raw materials, consume less energy, and generate less waste. All of these factors lead to a lower Cost of Goods Sold (COGS).

For example, Pfizer’s redesigned sertraline process not only eliminated millions of pounds of waste but also doubled the overall product yield. This means they could produce twice the amount of drug from a similar amount of input, drastically lowering the cost per kilogram. In the hyper-competitive generics market, these cost savings are typically passed on to the consumer in the form of lower prices to gain market share. Therefore, the widespread adoption of green chemistry should lead to even more affordable medicines in the long run, as it attacks the very source of inefficiency in manufacturing.

4. How does green chemistry apply to the development of more complex generics, like biosimilars or long-acting injectables, which seem more focused on formulation than API synthesis?

While the API synthesis is a major focus, green chemistry principles apply across the entire product lifecycle, including complex generics:

- Biosimilars: The production of biologics via cell culture is an energy- and water-intensive process that generates significant waste (e.g., single-use plastics, spent cell culture media). Green chemistry principles can be applied to optimize the cell culture media (e.g., using chemically defined, animal-free components), improve the efficiency of downstream purification processes (e.g., using greener buffer systems or novel chromatography resins that require less solvent), and develop more sustainable single-use technologies.

- Long-Acting Injectables/Complex Formulations: The manufacture of these products often involves polymers (like PLGA) and specialized solvents. Green chemistry can drive the development of biodegradable polymers from renewable sources. Furthermore, the use of greener, safer solvents in the formulation process is critical, as residual solvents are a major safety and quality concern. Technologies like supercritical fluid (scCO2) processing can be used to create drug-polymer microspheres without the use of harsh organic solvents.

- Analytical Chemistry: For all complex generics, the analytical burden is immense. Applying green analytical chemistry principles to the hundreds of quality control tests required can significantly reduce solvent consumption and waste across the QC labs.

5. What is the single most impactful action a generic company’s leadership can take to accelerate the adoption of green chemistry within their organization?

The single most impactful action is to change the metrics and incentives for the R&D and process chemistry teams.

Currently, many R&D teams are primarily incentivized by “speed to filing.” This can inadvertently encourage the development of fast but inefficient processes, shifting the long-term cost burden to manufacturing. To break this cycle, leadership must introduce and elevate lifecycle-based metrics like Process Mass Intensity (PMI) as a key performance indicator (KPI) for the development team, right alongside timeline adherence.

When a process chemist’s success is measured not just by how fast they develop a route, but by how low its PMI is, their entire approach changes. They are now incentivized to think about waste, solvent choice, and catalytic efficiency from day one. This aligns the goals of R&D with the goals of manufacturing and the company as a whole. It makes the long-term cost of a process visible at the design stage, where it can be most effectively managed. This strategic shift in performance measurement, cascaded down from the executive level, will do more to foster a culture of green chemistry than any single technology investment.

References

- Understanding the Lifecycle of Generic Drugs: From Patent Cliffs to …, accessed July 30, 2025, https://www.drugpatentwatch.com/blog/understanding-the-lifecycle-of-generic-drugs-from-development-to-market-impact/

- Generic Drug Development – MRIGlobal, accessed July 30, 2025, https://www.mriglobal.org/blog-generic-drug-development/

- FDA Critical Path Initiatives: Opportunities for Generic Drug Development – PMC, accessed July 30, 2025, https://pmc.ncbi.nlm.nih.gov/articles/PMC2751455/

- What Pharma Needs to Know About Green Chemistry – News-Medical.net, accessed July 30, 2025, https://www.news-medical.net/life-sciences/What-Pharma-Needs-to-Know-About-Green-Chemistry.aspx

- Green Chemistry in Pharmaceutical Applications, accessed July 30, 2025, https://www.pharmtech.com/view/green-chemistry-pharmaceutical-applications

- Green Chemistry Approaches in Pharmaceutical Synthesis: Sustainable Methods for Drug Development – MDPI, accessed July 30, 2025, https://www.mdpi.com/2673-9623/5/2/13

- 12 Principles of Green Chemistry – Sigma-Aldrich, accessed July 30, 2025, https://www.sigmaaldrich.com/US/en/technical-documents/technical-article/analytical-chemistry/green-chemistry-principles

- Green Chemistry Principles: A Commitment to Sustainable Medicine, accessed July 30, 2025, https://blog.sekisuidiagnostics.com/dxdialogue/green-chemistry-principles-a-commitment-to-sustainable-medicine

- Johnson & Johnson Innovative Medicine, accessed July 30, 2025, https://innovativemedicine.jnj.com/sustainability/green-chemistry

- The 12 Principles of Green Chemistry Pocket Guide, accessed July 30, 2025, https://www.acs.org/content/dam/acsorg/greenchemistry/redesign/principles/the-12-principles-of-green-chemistry-pocket-guide.pdf

- Green Chemistry – American Society of Brewing Chemists, accessed July 30, 2025, https://www.asbcnet.org/lab/Pages/GreenChemistry.aspx

- 12 Principles of Green Chemistry – American Chemical Society, accessed July 30, 2025, https://www.acs.org/green-chemistry-sustainability/principles/12-principles-of-green-chemistry.html

- Benefits of Green Chemistry | US EPA, accessed July 30, 2025, https://www.epa.gov/greenchemistry/benefits-green-chemistry

- Sustainable Pharma Labs Using Green Chemistry | Pharmaceutical Engineering, accessed July 30, 2025, https://ispe.org/pharmaceutical-engineering/ispeak/sustainable-pharma-labs-using-green-chemistry