In the pharmaceutical sciences innovation often arrives not with a bang, but with a quiet, paradigm-shifting refinement. For decades, the conventional tablet has reigned supreme—a monolithic, reliable, and cost-effective workhorse of oral drug delivery. Yet, its one-size-fits-all nature has consistently presented challenges for the most vulnerable among us: the very young and the very old. The struggle to swallow a large pill, the imprecision of splitting a scored tablet, the instability of liquid formulations—these are not minor inconveniences; they are fundamental barriers to therapeutic success. What if the solution wasn’t a radical reinvention, but a radical reduction? What if, by making the tablet smaller, we could make its impact exponentially larger?

This is the story of the mini-tablet, a dosage form that is quietly but decisively revolutionizing how we think about, develop, and deliver oral medications. This is not merely a tale of miniaturization. It is a narrative of enhanced precision, unprecedented flexibility, and profound patient-centricity. By deconstructing the monolithic tablet into a multiparticulate system, we unlock a cascade of therapeutic and commercial advantages that touch every stage of the pharmaceutical value chain—from early-stage clinical development and manufacturing to patient adherence and strategic life cycle management.

This report will guide you, the pharmaceutical professional, through this small revolution. We will move beyond the simple definition of a mini-tablet to explore its identity as a sophisticated platform technology. We will dissect the nuanced science of its manufacture, the strategic imperatives of its quality control, and the artistry of its advanced formulations. We will journey from the bench to the bedside, examining real-world clinical applications that are transforming patient outcomes. Finally, we will look to the horizon, where mini-tablets are poised to merge with digital health and 3D printing to usher in an era of truly personalized medicine. Prepare to think small, because the future of oral drug delivery is proving to be anything but.

Beyond Size: Redefining the Oral Solid Dosage Paradigm

To truly grasp the transformative potential of mini-tablets, we must first move beyond the intuitive but incomplete notion that they are simply “small pills.” While their size is their most defining physical characteristic, it is the consequence of that size—the transition from a single-unit to a multiple-unit dosage form—that constitutes the genuine paradigm shift. This fundamental change is the wellspring from which all other benefits flow, transforming a simple dosage form into a versatile and powerful drug delivery platform.

At its core, a mini-tablet is a solid oral dosage form with a diameter typically measuring 3 mm or less.1 Industry consensus generally places them in the 1 to 4 mm range, though no formal regulatory guidelines currently exist to codify this definition.5 This ambiguity means that the smallest mini-tablets, particularly those under 2.5 mm, are sometimes referred to as “oral granules,” a classification that highlights their functional similarity to other multiparticulate systems.2 These tiny units are rarely administered alone due to handling difficulties; instead, they are typically filled into hard gelatin or HPMC capsules, packaged into sachets, or even compressed into a larger, rapidly disintegrating tablet that serves as a carrier.2

This approach embodies the foundational principle of Multiple Unit Dosage Forms (MUDFs): the division of a total therapeutic dose into a multitude of discrete subunits.7 Instead of a patient swallowing one large object, they swallow a single capsule containing dozens or even hundreds of tiny, independent drug delivery units. This seemingly simple change has profound implications for how a drug behaves in the body and how patients experience their therapy. As noted by Dr. Sarah Johnson, a leading pharmaceutical research scientist,

“Mini-tablets represent a paradigm shift in pharmaceutical dosage forms, offering unprecedented flexibility in drug delivery and dosing”.9

This flexibility reframes the mini-tablet from a final product into a highly controlled, standardized intermediate—a pharmaceutical “building block.” The implications of this are far-reaching. A manufacturer can produce a single, large bulk batch of mini-tablets with specific, well-characterized properties. This one batch can then become the foundation for an entire product line. Need a 50 mg dose? Fill a capsule with 25 mini-tablets of 2 mg each. Need a 100 mg dose for a different patient population? Use the exact same bulk batch and fill a capsule with 50 mini-tablets.5 This “platform” approach offers staggering advantages in manufacturing and supply chain logistics. It decouples the core manufacturing campaign (producing the bulk mini-tablets) from the final packaging and dosing step. This allows for a “make-to-order” system that can respond rapidly to fluctuating market demands for different strengths, reducing inventory waste and minimizing the need for multiple, costly formulation development programs for each dosage strength.5 For business leaders focused on operational efficiency, supply chain agility, and SKU rationalization, this platform concept is the first and most crucial strategic insight to grasp. Mini-tablets are not just a better pill; they are a smarter way to build a product portfolio.

The Patient at the Center: A Quantum Leap in Adherence and Acceptability

For any therapy to be effective, it must first be taken. This simple truth lies at the heart of the pharmaceutical industry’s persistent challenge: patient adherence. For vulnerable populations, particularly children and the elderly, the physical act of taking medication can be the greatest barrier to care. Conventional tablets are often too large, liquids can be unpalatable and prone to dosing errors, and the complexity of managing multiple medications can be overwhelming. Mini-tablets directly address these core issues, representing a quantum leap forward in patient-centric formulation design. Their development is not just a technical achievement but a response to a clear and urgent medical need, a sentiment echoed by the World Health Organization’s call for more age-appropriate solid dosage forms.10

Solving the Dysphagia Dilemma: A New Dawn for Pediatric and Geriatric Care

Dysphagia, or difficulty swallowing, is a pervasive problem that significantly impacts medication adherence in both the youngest and oldest patients.4 Mini-tablets offer an elegant and effective solution.

For pediatric patients, the promise is immense. A growing body of clinical evidence demonstrates the high acceptability of mini-tablets in children, with studies showing successful administration in infants as young as six months old.11 In direct comparisons, mini-tablets have often been shown to be superior to the traditional gold standard of pediatric care—liquid formulations. One landmark study found that the acceptance of 2 mm mini-tablets was significantly higher than that of syrup in children aged 0.5 to 6 years, with even the youngest infants (6-12 months) fully capable of swallowing them.15 This is largely due to the flexibility of administration; mini-tablets can be sprinkled onto a spoonful of soft food like applesauce or yogurt, or mixed with a small amount of liquid.5 This approach seamlessly integrates medication time into a meal, transforming a potentially stressful and combative event into a routine, non-threatening experience. It also circumvents the common pitfalls of liquid medicines, which often have a bitter taste that is difficult to mask, require careful measurement that is prone to caregiver error, and can suffer from stability and microbial contamination issues.17

For geriatric patients, the challenges are often compounded by polypharmacy—the concurrent use of multiple medications to manage multiple chronic conditions.9 The daily routine of managing a complex regimen of numerous, often large, tablets can be confusing and burdensome, leading to unintentional non-adherence. Mini-tablets provide a powerful tool for simplification. By combining multiple active pharmaceutical ingredients (APIs)—each formulated as a distinct mini-tablet—into a single capsule, a complex regimen can be consolidated into a single, easy-to-swallow dose.12 This aligns perfectly with the preferences of older adults, who have been shown in studies to favor smaller solid oral dosage forms.22 A tablet size of 7-8 mm is often cited as preferred, but for those with swallowing disorders, sizes as small as 6.5 mm are necessary—a requirement that mini-tablets easily meet.22

To fully appreciate the strategic positioning of mini-tablets, a direct comparison with other common dosage forms is essential.

Comparative Analysis of Oral Dosage Forms

| Feature | Mini-Tablets (in Capsule/Sachet) | Monolithic Tablets | Liquid Formulations | Pellets/Granules |

| Dose Flexibility | High (dose adjusted by count) 5 | Low (scoring is inaccurate) 2 | Moderate (dosing errors common) 9 | Moderate (volume-based) 8 |

| Patient Acceptability (Pediatric/Geriatric) | Very High 15 | Low (dysphagia) 8 | Moderate (taste, volume issues) 23 | High (can be sprinkled) 24 |

| Manufacturing Complexity | Moderate-High 25 | Low 3 | Moderate (stability, microbial) 19 | High (extrusion-spheronization) 7 |

| Pharmacokinetic Profile | Predictable, low variability 3 | High variability, risk of dose dumping 24 | Variable absorption 26 | Predictable, low variability 27 |

| Combination Therapy | Excellent (combine different mini-tablets) 7 | Limited (fixed-dose only) | Very limited (stability issues) | Good (can blend pellets) |

| Stability | High 3 | High | Low 19 | Moderate |

This comparative analysis crystallizes the unique value proposition of mini-tablets. While they may involve a higher manufacturing investment than conventional tablets, they offer a superior profile in nearly every patient-centric and pharmacokinetic metric. For a pharmaceutical company, this table is not just a summary of features; it is a strategic roadmap, identifying the specific therapeutic areas and patient populations where mini-tablet technology can provide a decisive and defensible competitive advantage.

The development of age-appropriate formulations is not merely a commercial opportunity; it is a regulatory and ethical imperative. Both the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have established strong mandates, such as the Pediatric Research Equity Act (PREA) and the Paediatric Regulation, respectively, to encourage and require the development of medicines suitable for children.28 A significant hurdle in conducting the necessary pediatric clinical trials is the logistical challenge of dose-finding across a wide spectrum of ages and body weights. Historically, this has required the use of extemporaneously compounded liquid formulations, which are often prepared in hospital pharmacies. These formulations can suffer from a lack of robust stability data, potential for dosing inaccuracies, and variability between clinical sites.17

This is where the platform nature of mini-tablets offers a profound strategic advantage that extends beyond patient adherence into the realm of clinical development itself. A single, stable, GMP-manufactured batch of mini-tablets can serve as the clinical trial material for an entire pediatric program.5 Dose adjustments for different age or weight cohorts are achieved simply by varying the number of mini-tablets counted into a capsule or sachet. This approach ensures dose consistency and accuracy across all trial participants and sites, eliminates the risks associated with unstable liquid preparations, and dramatically simplifies the Chemistry, Manufacturing, and Controls (CMC) section of a regulatory submission. By de-risking and streamlining the operational complexities of pediatric trials, companies can accelerate their development timelines, reduce costs, and increase the likelihood of a successful submission, making the pursuit of pediatric indications a more commercially viable and scientifically robust endeavor.

The Psychology of Adherence: Beyond Just Swallowing

Improving medication adherence is a complex challenge that extends beyond the purely physical act of swallowing. It involves psychological and behavioral factors, particularly for children and their caregivers. Mini-tablets, through their unique administration flexibility, tap into these deeper aspects of adherence, empowering patients and reducing the anxiety that often surrounds medication time.

For caregivers, the precision of a mini-tablet dose provides a powerful sense of reassurance. The task of measuring a precise volume of a liquid medication, often in the middle of the night with a distressed child, is fraught with potential for error. Spillage, incorrect measurement, and a child spitting out a portion of the dose can all lead to uncertainty and anxiety about whether the correct amount of drug was delivered.9 Counting out a specific number of mini-tablets onto a spoonful of applesauce is a far more discrete, tangible, and controllable action, reducing caregiver stress and increasing confidence in the accuracy of the dose.

For children, this method of administration can be transformative. By integrating the medication into a familiar and pleasant food, the negative associations with “medicine time” can be mitigated. This approach aligns with play-based therapeutic techniques, which have been shown to significantly reduce procedural anxiety and increase cooperation in young patients.31 Instead of a confrontation, it becomes a simple part of a meal. This subtle shift in context can have a profound impact on a child’s willingness to take their medication consistently, which is particularly critical for chronic conditions or courses of antibiotics where incomplete treatment can have serious consequences.31

It is important to acknowledge the nuances of patient behavior. Some studies have observed that older children (e.g., 2-8 years old) may have a tendency to chew mini-tablets, which can result in lower “swallowability” scores in clinical studies compared to fine granules or liquids that are swallowed directly.23 This finding does not diminish the overall high acceptability of mini-tablets but rather underscores the importance of formulation design. If a child is likely to chew the mini-tablet, effective taste-masking via a functional coating becomes absolutely critical to prevent exposure to a bitter-tasting API and ensure a positive experience.11 This highlights the need for a holistic approach that considers not just the physical form of the dosage but also the likely interactions of the patient with that form.

The Science of Small: Manufacturing and Formulation Nuances

The elegant simplicity of the mini-tablet from a patient’s perspective belies a sophisticated and nuanced manufacturing process. While the fundamental principles of tablet production remain, the small scale introduces unique challenges and demands specialized technologies to ensure quality, consistency, and commercial viability. Mastering this “science of small” requires a deep understanding of powder behavior, granulation techniques, and the specialized equipment that forms the engine room of mini-tablet production.

Core Manufacturing Technologies: A Tale of Two Granulations

The journey from raw API and excipients to a finished mini-tablet typically follows one of several established pathways, with the choice depending largely on the physicochemical properties of the powder blend.

The most straightforward and cost-effective method is Direct Compression (DC). In this process, the API and a carefully selected blend of excipients are simply mixed and then compressed directly into mini-tablets.32 The primary advantage of DC is its simplicity; it avoids the use of liquids (solvents or water), which enhances the stability of moisture-sensitive drugs and eliminates a costly and time-consuming drying step.3 However, DC places extreme demands on the powder blend itself. To flow uniformly and consistently into the tiny die cavities of a tablet press—often only 2 or 3 mm in diameter—the powder must possess excellent flowability and compressibility. For many formulations, especially those with a high drug load or an API with poor physical properties, achieving this is a significant challenge.34

When the powder blend is not suitable for DC, manufacturers turn to granulation. This process involves agglomerating the fine powder particles into larger, more free-flowing granules, which then feed uniformly into the tablet press.

- Wet Granulation is the most traditional and widely used method. It involves adding a liquid binder to the powder mixture to form a wet mass, which is then milled and dried to produce granules.32 While highly effective at improving powder properties, it is a multi-step process that introduces liquid and heat, potentially compromising the stability of sensitive APIs.

- Dry Granulation, often performed via a process called roll compaction, offers a simpler, solvent-free alternative. In this method, the powder blend is compressed between two rollers to form a dense ribbon or “slug,” which is then milled into granules of the desired size.32 This approach sits between the simplicity of DC and the complexity of wet granulation, providing a valuable option for moisture-sensitive formulations.

It is also useful to compare these methods to the primary technology used for producing pellets, a similar multiparticulate system. Pellets are typically manufactured via extrusion-spheronization, a more complex and often more expensive process that involves extruding a wet mass into spaghetti-like strands, which are then broken and rounded in a spheronizer.35 The ability to produce mini-tablets using conventional tableting techniques like DC or dry granulation represents a significant advantage over pellets, offering a more streamlined, reproducible, and cost-effective manufacturing pathway that avoids the complexities of solvent handling and spheronization.1

Specialized Equipment: The Engine Room of Mini-Tablet Production

At the heart of production lies the tablet press. Mini-tablets are manufactured on the same types of rotary tablet presses used for conventional tablets, a fact that allows manufacturers to leverage existing infrastructure and expertise.1 Leading equipment suppliers such as

Fette Compacting and Korsch offer a wide range of machines suitable for this purpose, from smaller, instrumented presses for research and development to high-speed, multi-station presses for large-scale commercial production.37

The key enabling technology, however, is not the press itself, but the specialized tooling used within it. Multi-tip tooling is the innovation that makes high-volume mini-tablet production commercially feasible. Instead of a single punch tip compressing one tablet per station with each rotation of the press turret, a multi-tip punch holds several smaller tips (e.g., 24 tips on a single punch body).36 This allows a single press station to produce multiple mini-tablets simultaneously, dramatically multiplying the output of the machine without increasing its rotational speed.1

While this technology is critical for scalability, it comes with its own set of challenges. Multi-tip tools are more complex and labor-intensive to manufacture, requiring tighter machining tolerances and resulting in a higher upfront cost.25 They are also more delicate. The individual punch tips have a high length-to-diameter ratio, making them more susceptible to damage from non-axial stresses during compression or from improper handling during setup and cleaning.1 This has led to the development of specialized tool management systems, like Fette Compacting’s patented TRI.EASY toolboxes, which are designed to safely transport, store, and clean these sensitive tools.37

This delicate nature of the tooling creates a crucial, symbiotic relationship with the formulation itself. As noted, mini-tablet production generally requires lower compression forces than are needed for larger, conventional tablets.1 This is fortunate, as the slender multi-tip punches are not designed to withstand the high axial forces used in standard tableting. This reality means that formulation scientists and process engineers cannot operate in silos. The development of a successful mini-tablet product requires an integrated approach from the very beginning. The choice of excipients must be guided not only by the desired drug release profile but also by the need to create a powder blend with superior flow and compressibility characteristics that can form a robust tablet under relatively low compression force. A formulation that is difficult to compress is fundamentally incompatible with the high-output, multi-tip tooling required for commercial scale-up. A failure to align these formulation properties with the mechanical limitations of the tooling will inevitably lead to significant and costly problems during the transition from development to manufacturing, underscoring the absolute necessity of a Quality by Design (QbD) framework.

Precision and Control: Mastering Quality in Mini-Tablet Production

In the world of mini-tablet manufacturing, quality is a game of microns and milligrams. Because the final dose is an aggregate of many small units, the consistency of each individual unit is paramount. The primary technical hurdle, and the intense focus of quality control efforts, is ensuring uniformity—specifically, the uniformity of weight and API content from one mini-tablet to the next. Even a small absolute deviation can represent a large relative error in a tiny tablet, increasing the risk of batch failure and compromising dose accuracy for the patient.25 Achieving this level of precision requires a deep understanding of the root causes of variability and the deployment of advanced process control strategies.

The Uniformity Challenge: Every Milligram Matters

The challenge of ensuring dose uniformity, as defined by standards like USP Content Uniformity, is magnified in mini-tablet production.41 Several factors can conspire to introduce variability into the process.

The most critical factor is poor powder flow. The journey of the powder blend from the hopper of the tablet press into the small die cavities must be smooth, rapid, and consistent. If the powder flows erratically, some dies will be under-filled while others are over-filled, leading directly to variations in mini-tablet weight and, consequently, API content.25 The small diameter of the dies exacerbates this problem, making them less forgiving of sub-optimal powder properties. This is why so much development effort is focused on granulation and the selection of excipients that promote flow. Studies have demonstrated the significant impact of equipment design on this step; for instance, using a forced feeder, which actively pushes powder into the dies, can dramatically reduce weight variation compared to a passive open feeder that relies on gravity.44

Another significant cause of non-uniformity is particle segregation. Even a perfectly homogenous powder blend can become non-uniform during handling. As the blend is transported and tumbles in the press hopper, finer particles can sift through coarser ones, or particles of different densities can separate.43 This can lead to stratification of the API within the hopper, meaning that mini-tablets produced at the beginning of a manufacturing run may have a different potency than those produced at the end.

Finally, mini-tablets face a unique challenge at the final packaging stage: fill count errors. When filling sachets or capsules with a low number of mini-tablets (e.g., a dose of 1 to 4 units), a single miscount by the packaging equipment can result in a catastrophic dose error—a 25% or even 100% deviation from the intended dose. This type of error is particularly insidious because it is often undetectable by standard in-process weight-checking equipment; the weight of a single mini-tablet is often less than the variance of the empty sachet or the limit of detection of the scale.41 This places a heavy burden on the precision and reliability of the counting and filling machinery.

Process Analytical Technology (PAT): The Path to Real-Time Quality Assurance

The traditional approach to quality control in pharmaceuticals has been one of “testing quality in” after the fact. A batch is produced, samples are taken to a lab, and days later, the results determine if the batch can be released. This is an inefficient and reactive model. The modern, FDA-endorsed approach is Process Analytical Technology (PAT), a framework for designing, analyzing, and controlling manufacturing through timely, in-process measurements of critical quality and process parameters.45 PAT is about building quality into the process from the start and monitoring it in real-time.

A cornerstone of PAT in solid dosage manufacturing is Near-Infrared (NIR) Spectroscopy. This non-destructive analytical technique can be integrated directly into the manufacturing line to provide a real-time assessment of the powder blend’s composition.48 An NIR probe placed in the feed frame of the tablet press can continuously monitor the blend for homogeneity, ensuring that the API is evenly distributed

before it is compressed into mini-tablets.49 If the system detects a deviation from the target concentration, it can trigger an alarm or even automatically divert the non-conforming material, preventing the creation of an entire batch of out-of-specification product. This proactive control represents a massive improvement in efficiency and quality assurance.

The ultimate ambition of a PAT-driven strategy is Real-Time Release Testing (RTRT). This is a state where the quality of the final product can be assured based on the data collected during the manufacturing process, eliminating the need for extensive end-product testing.52 For complex multiparticulate systems like coated mini-tablets, this requires sophisticated tools. For example, technologies like

Optical Coherence Tomography (OCT) are now being used in-line to monitor the thickness and uniformity of functional coatings on pellets and mini-tablets as they are being applied in a fluid bed coater.53 By ensuring this critical quality attribute is met in real-time, manufacturers can move closer to the goal of releasing a batch the moment it is finished, dramatically shortening production cycles.

This embrace of real-time data and control does more than just improve the quality of a single batch; it serves as the essential technological foundation for a much larger strategic transformation: the shift from batch to Continuous Manufacturing (CM).45 In a CM process, raw materials are fed continuously into one end of an integrated line and finished products emerge from the other, without interruption. This model is impossible to manage without the robust, in-line monitoring and control that PAT provides. Mini-tablets, as a standardized intermediate product, are exceptionally well-suited to this model. One can envision a continuous line producing bulk mini-tablets, which are then fed into a highly flexible, on-demand packaging line.

This capability fundamentally reshapes the pharmaceutical supply chain. It enables a transition from the traditional, inefficient “make-to-stock” model—which relies on large, costly inventories and is slow to respond to market changes—to a lean and agile “make-to-order” model.5 In this new paradigm, a company can respond almost instantly to a spike in demand for a particular dosage strength. This not only reduces inventory carrying costs and the risk of product expiration but also provides a powerful competitive advantage in a market that increasingly demands personalized medicine and a proliferation of different dosage strengths (“image proliferation”).5 Thus, the implementation of PAT for mini-tablet production is not just a quality control initiative; it is a catalyst for a complete business process transformation that enhances agility, reduces costs, and builds a more resilient supply chain.

Beyond the Pill: Advanced Formulations and Functional Coatings

The true genius of the mini-tablet platform lies not just in its physical form, but in its capacity to serve as a versatile canvas for advanced formulation science. Once the core mini-tablet is manufactured with precision and uniformity, it becomes a substrate for a wide array of functional modifications. Through the artful application of polymer coatings and the clever combination of different mini-tablet populations, formulators can engineer sophisticated drug delivery systems that control the rate, timing, and location of drug release with remarkable precision. This capability transforms the humble mini-tablet into a tool for creating highly differentiated products, from complex combination therapies to multi-phasic release profiles, all within a single dosage form.

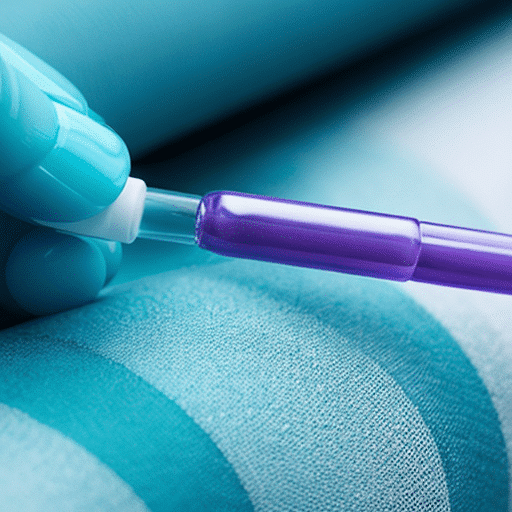

Engineering Release Profiles: The Art of Functional Coating

The physical characteristics of mini-tablets make them an ideal substrate for functional film coating. Compared to irregularly shaped granules or porous pellets, mini-tablets possess a highly uniform size and shape, a smooth surface, and high mechanical strength.1 This consistency allows for the application of polymer coatings in a highly reproducible manner, leading to more predictable and reliable drug release performance. This process is typically carried out in a perforated pan coater or a fluid bed system equipped with a Wurster insert.25 A variety of functional coatings can be applied to achieve specific therapeutic objectives:

- Taste-Masking: For pediatric and geriatric formulations, palatability is paramount. A thin polymer coating can effectively mask the bitter or unpleasant taste of an API during the brief time the mini-tablet is in the mouth, dramatically improving acceptability and adherence.5

- Enteric Coating (Delayed Release): This is one of the most common functional coatings. By using pH-sensitive polymers, such as polymethacrylates (e.g., Eudragit®) or cellulose derivatives, formulators can create a coating that is insoluble in the acidic environment of the stomach (pH 1-3) but dissolves readily in the more alkaline conditions of the small intestine (pH > 5.5).57 This is essential for protecting acid-labile drugs from degradation in the stomach or for preventing gastric irritation caused by drugs like NSAIDs.

- Sustained/Controlled Release: To reduce dosing frequency and improve patient compliance, mini-tablets can be coated with water-insoluble polymers, such as ethylcellulose, or formulated as a matrix system containing hydrophilic polymers like HPMC.27 These formulations slow the release of the drug over an extended period (e.g., 12 or 24 hours), maintaining therapeutic drug concentrations in the body for longer and avoiding the peaks and troughs associated with immediate-release products.

The Polypill Reimagined: Combination Therapy in a Single Capsule

Perhaps the most powerful application of mini-tablet technology is its ability to facilitate complex combination therapies. Many chronic diseases, such as cardiovascular disease, HIV, and diabetes, are managed with multiple medications. Adhering to a regimen of several different pills taken at different times can be a significant burden for patients. Fixed-Dose Combinations (FDCs), often called “polypills,” which combine multiple APIs into a single tablet, have been developed to simplify these regimens and improve adherence.60

Mini-tablets elevate the FDC concept to a new level of sophistication. A major challenge in developing traditional FDCs is dealing with chemical incompatibility between different APIs. If two drugs cannot be mixed in the same powder blend, they must be physically separated, often through complex and costly manufacturing processes like producing a bi-layer tablet. Mini-tablets offer a simple and elegant solution. Each API can be formulated and manufactured as its own distinct mini-tablet, complete with any necessary functional coating. These different populations of mini-tablets can then be easily combined by counting the desired number of each into a single capsule.7

This “tablet-in-a-capsule” approach unlocks the potential for creating truly advanced multi-phase release systems. A single capsule can become a microcosm of a complex therapeutic regimen, containing a carefully curated mix of mini-tablets, each programmed for a specific task 7:

- A population of immediate-release mini-tablets to provide a rapid loading dose for quick onset of action.

- A population of sustained-release mini-tablets of the same drug to maintain its therapeutic effect over many hours.

- A population of enteric-coated mini-tablets of a second, incompatible drug that needs to be delivered to the small intestine.

This level of control and flexibility is difficult, if not impossible, to achieve with any other single oral dosage form. It moves beyond simple dose adjustment for different patient weights and into the realm of true regimen personalization. This capability has profound implications for both clinical development and patient care. In “dose-finding” clinical trials, researchers can investigate numerous dose combinations and release profiles using a limited number of bulk mini-tablet batches, simply by altering the mix and count in the capsules provided to participants.65 Looking to the future, one can envision a paradigm of “dynamic dosing,” where a physician could adjust a patient’s therapy not by writing a prescription for a new drug product, but by electronically transmitting instructions to a pharmacy’s automated dispenser to change the number and type of mini-tablets in the patient’s next monthly supply. This represents a foundational step away from mass-produced medicine and toward a future of highly individualized, adaptable pharmacotherapy.

The Pharmacokinetic Advantage: Predictability and Safety

The journey of a drug from ingestion to its site of action is governed by the principles of pharmacokinetics (PK)—the study of its absorption, distribution, metabolism, and excretion. The ultimate goal of any oral dosage form is to deliver the drug to the bloodstream in a predictable and reproducible manner, achieving a plasma concentration that is high enough to be effective but not so high as to be toxic. It is in this critical domain that the multiparticulate nature of mini-tablets offers one of its most significant and scientifically robust advantages over traditional monolithic tablets.

To understand this advantage, it is essential to grasp two key PK parameters: Cmax, the maximum or peak drug concentration achieved in the plasma, and AUC (Area Under the Curve), which represents the total drug exposure over time.26 For many drugs, high Cmax values are associated with an increased incidence of side effects, while a consistent AUC is necessary for therapeutic efficacy.

Reducing Variability and Dose Dumping

A conventional single-unit dosage form (SUDF), such as a large tablet, is subject to the highly variable and often unpredictable process of gastric emptying. Its transit from the stomach to the small intestine—the primary site of drug absorption—can be significantly influenced by the presence or absence of food. This can lead to an “all-or-nothing” effect, where the tablet is either retained in the stomach for a prolonged period or emptied rapidly, resulting in high inter- and intra-patient variability in the rate and extent of drug absorption.3 This unpredictability is a major source of inconsistent therapeutic outcomes.

Mini-tablets, as a MUDF, behave very differently. When the carrier capsule dissolves in the stomach, the dozens or hundreds of tiny mini-tablets disperse. They do not behave as a single large object but rather more like a fluid, allowing them to empty from the stomach gradually and more predictably, largely independent of the digestive state.24 This predictable gastrointestinal transit has two crucial benefits:

- Lower Cmax Fluctuations: The gradual emptying and dissolution of numerous small units result in a smoother and more controlled absorption profile. This avoids the sharp spike in plasma concentration (a high Cmax) that can occur with a rapidly dissolving monolithic tablet. By blunting this peak, mini-tablets can significantly reduce the risk of concentration-dependent side effects, leading to a safer and better-tolerated medication.1

- Mitigation of Dose Dumping: This safety advantage is even more pronounced for controlled-release formulations. A controlled-release monolithic tablet relies on a single barrier—either a coating or a matrix—to regulate drug release over many hours. If this single barrier fails (e.g., due to a manufacturing defect or a patient chewing the tablet), the entire drug dose can be released at once. This phenomenon, known as “dose dumping,” can lead to dangerously high, potentially toxic plasma concentrations. With a mini-tablet system, the dose is distributed across hundreds of independent units. The failure of the release-controlling mechanism on a few of these units would have a negligible impact on the overall drug release profile, making the system inherently safer and more robust.8

This inherent predictability and safety profile unlocks a significant strategic opportunity for pharmaceutical developers. Many promising drug candidates are abandoned during development because they have a Narrow Therapeutic Index (NTI). These are compounds for which the window between a therapeutic concentration and a toxic concentration is very small. The high pharmacokinetic variability of conventional oral dosage forms makes it extremely difficult to safely administer NTI drugs, as unpredictable absorption could easily push plasma levels into the toxic or, conversely, the sub-therapeutic range.

The demonstrated ability of mini-tablet technology to reduce PK variability and dampen Cmax fluctuations provides a potential solution to this problem.1 By delivering NTI drugs in a more controlled and predictable manner, a mini-tablet formulation could make their oral administration safe and viable. This creates a powerful value-creation opportunity in two ways. First, it could enable the “rescue” of promising NTI compounds that failed in late-stage development due to PK challenges, reviving stalled pipeline assets. Second, it allows for the reformulation of existing NTI drugs that are currently administered via more burdensome routes (e.g., injection) or that require intensive therapeutic drug monitoring. By creating a safer, more reliable oral version of such a drug, a company can develop a highly differentiated product with a significant clinical and commercial advantage. This positions mini-tablet technology not just as an improvement for existing drugs, but as an enabling platform for a new class of oral therapies.

From Bench to Bedside: Clinical Applications and Therapeutic Successes

The theoretical advantages of mini-tablets—patient-centricity, formulation flexibility, and pharmacokinetic predictability—are not merely academic concepts. They are being translated into tangible clinical benefits across a wide range of therapeutic areas. By examining specific case studies, we can see how this versatile dosage form is being deployed to solve real-world clinical challenges, improve patient outcomes, and create new therapeutic possibilities.

Case Study 1: Pediatrics – Acetylsalicylic Acid (ASA) for Kawasaki Disease

Kawasaki disease is an acute inflammatory illness that primarily affects young children and requires treatment with high doses of acetylsalicylic acid (aspirin). Administering the correct dose to small children using adult tablet formulations is challenging and prone to error. A retrospective case series in Japan investigated the use of specially prepared 3 mm, 10 mg ASA mini-tablets in children aged 1 to 4 years with the disease.14 The results were compelling: all patients successfully took 100% of their prescribed doses over treatment periods lasting more than two months. Crucially, no adverse events related to ingestion, such as choking or coughing, were reported. This study, though small, provided crucial real-world evidence of the feasibility, acceptability, and safety of using an active mini-tablet formulation in a vulnerable pediatric population, validating the dosage form’s potential to improve adherence and dosing accuracy in acute pediatric care.14

Case Study 2: Geriatrics – Rivastigmine for Alzheimer’s Disease

Treating patients with Alzheimer’s disease presents a dual challenge: cognitive impairment can make adherence to complex regimens difficult, and these elderly, often frail, patients frequently suffer from dysphagia and are sensitive to gastrointestinal side effects. An ongoing multi-center observational study is currently evaluating the efficacy, safety, and compliance of a novel rivastigmine mini-tablet formulation in patients with mild to moderate Alzheimer’s.68 The explicit rationale for developing this formulation is twofold: first, to address swallowing difficulties by significantly reducing the size of the dosage form, and second, to minimize common GI side effects like nausea and vomiting by creating an optimized drug release profile.69 This clinical trial perfectly encapsulates the strategic use of mini-tablet technology to directly target the primary barriers to effective treatment in a challenging geriatric population.

Case Study 3: Cardiovascular – The “Polypill” Reimagined

The long-term management of cardiovascular disease often requires a combination of medications, including anti-hypertensives, statins, and anti-platelet agents. A groundbreaking study sought to improve adherence in high-risk patients by developing a four-in-one “polypill” using mini-tablet-in-capsule technology.71 The formulation combined four distinct mini-tablet populations within a single capsule: immediate-release hydrochlorothiazide and simvastatin for rapid effect, and sustained-release metoprolol succinate and aspirin for prolonged therapeutic coverage. This innovative approach demonstrates the unique ability of mini-tablets to facilitate complex FDCs of incompatible drugs with different release requirements, simplifying the regimen for patients and potentially reducing cardiovascular mortality.71 This concept builds on the success of existing multiparticulate systems like the extended-release formulation of metoprolol succinate, which uses a multitude of controlled-release pellets to provide predictable, once-daily beta-blockade.72

Case Study 4: Oncology – A Patient-Centric Future for Oral Chemotherapy

The field of oncology is rapidly shifting towards targeted oral therapies, such as small-molecule kinase inhibitors (SMKIs).75 While more convenient than intravenous chemotherapy, these regimens can be complex, and adherence is critical for success. Drugs like capecitabine are available as large tablets that cannot be crushed, posing a challenge for patients with swallowing difficulties.77 This has led to the development of compounded oral liquid versions to improve convenience.79 Mini-tablets represent a superior alternative, offering the dosing flexibility and ease of administration of a liquid (when sprinkled on food) but with the inherent stability and precise dosing of a solid oral dosage form.62 For complex regimens involving drugs like temozolomide, where side effects can be a barrier to adherence, a more patient-friendly mini-tablet formulation could significantly improve the patient experience and treatment outcomes.81

These clinical applications reveal a deeper strategic potential. The challenges in modern medicine often lie not with a single disease, but with managing comorbidities. Consider the case of oral SMKIs in oncology. While highly effective, many of these agents are known to cause cardiotoxic side effects, requiring careful monitoring and sometimes the co-administration of cardioprotective drugs like beta-blockers or ACE inhibitors.75 Adherence to both the anti-cancer agent and the supportive care medication is essential for both efficacy and safety.

This is where a mini-tablet platform can offer a truly integrated therapeutic solution. A pharmaceutical company could develop a “co-packaged” therapy, a single capsule containing both the SMKI mini-tablets and the cardioprotective mini-tablets. This approach would ensure that the patient receives the complete, optimized regimen in a single, convenient dose, dramatically improving the likelihood of adherence to both critical medications. This positions the mini-tablet dosage form not merely as a vehicle for a single API, but as a sophisticated tool for integrated disease management. For a pharmaceutical company, this creates an opportunity to develop a highly differentiated product that offers a clear value proposition to patients, prescribers, and payers by simultaneously improving oncological outcomes and enhancing patient safety.

Navigating the Path to Market: The Regulatory Environment

The journey of any new pharmaceutical technology from laboratory concept to commercial reality is paved with regulatory milestones. For mini-tablets, the regulatory landscape is not a barrier but a powerful tailwind. Major regulatory bodies, including the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), have established frameworks that actively encourage, and in some cases mandate, the development of the very kind of patient-centric, age-appropriate formulations that mini-tablets exemplify. Understanding this environment is key to leveraging it as a strategic asset for accelerating product development and approval.

The Global Push for Better Medicines for Children

The most significant regulatory driver for mini-tablet development is the global focus on improving pharmacotherapy for children. For decades, pediatric medicine was an afterthought, with children often treated with “off-label” use of adult medications, involving crude practices like crushing tablets or splitting capsules. This led to widespread concerns about dosing accuracy, safety, and efficacy.

In response, the FDA implemented two key pieces of legislation: the Pediatric Research Equity Act (PREA) and the Best Pharmaceuticals for Children Act (BPCA).83 PREA requires pharmaceutical companies to conduct pediatric studies for new drugs that are likely to be used in children, while BPCA offers a powerful incentive—an additional six months of market exclusivity—for companies that voluntarily conduct such studies. A central component of this process is the submission of an Initial Pediatric Study Plan (iPSP), which must outline the company’s strategy for pediatric development, including plans for age-appropriate formulations.83 While the foundational guidance document, ICH E11, does not specifically name “mini-tablets,” its strong emphasis on the need for a variety of formulations (liquids, suspensions, chewable tablets) that allow for accurate dosing and are acceptable to children provides a clear regulatory rationale for their development.28

Similarly, the EMA established its Paediatric Regulation (EC No 1901/2006), which created the Paediatric Committee (PDCO) and requires companies to submit and agree upon a Paediatric Investigation Plan (PIP) for new medicines.29 The EMA has been particularly proactive in guiding industry on formulation, issuing a key “Guideline on pharmaceutical development of medicines for paediatric use” and a reflection paper on “Formulations of choice for the paediatric population”.29 These documents explicitly push developers away from extemporaneous preparations and towards well-characterized, stable, and palatable solid dosage forms suitable for children.

This concerted regulatory pressure fundamentally alters the development calculus. The appropriateness of the dosage form is no longer a secondary consideration; it is a primary focus of regulatory scrutiny. A company seeking approval for a new drug with a potential pediatric use can no longer simply submit adult clinical data and suggest that physicians crush the adult tablet. Regulators now expect a well-justified, data-supported plan for a formulation specifically designed for and tested in the target pediatric population.

This shift creates a significant strategic advantage for companies that proactively invest in advanced, age-appropriate dosage forms like mini-tablets. By approaching regulators with a comprehensive development plan that includes a robust mini-tablet formulation, a company demonstrates a deep commitment to pediatric safety and efficacy. They can present a complete package that addresses not only if the drug works, but how it can be used safely, effectively, and reliably in the real world by vulnerable patients and their caregivers. This proactive stance can lead to smoother interactions with regulatory agencies, a more predictable development pathway, and potentially a faster time-to-market. In this environment, the choice of dosage form becomes a critical component of a successful regulatory strategy.

The Strategic Imperative: Mini-Tablets as a Commercial Powerhouse

In the hyper-competitive pharmaceutical marketplace, scientific innovation must be inextricably linked to commercial strategy. Mini-tablet technology is not just a scientific curiosity; it is a powerful commercial tool that can be leveraged to capture market share, build defensible product franchises, and maximize the value of a company’s assets throughout their life cycle. For the savvy business leader, understanding how to deploy this technology is a strategic imperative.

Market Dynamics: Sizing the Opportunity

To understand the potential of mini-tablets, we must first look at the broader market they inhabit. The global Oral Solid Dosage (OSD) pharmaceutical market is colossal, valued at over USD 678 billion in 2023 and projected to soar past USD 1.2 trillion by 2032.87 Within this market, tablets remain the dominant dosage form, accounting for over half of the share.88

The growth of this market is fueled by powerful secular trends: the rising global prevalence of chronic diseases requiring long-term therapy, a rapidly aging population, and an increasing healthcare focus on patient-centricity and adherence.90 These are the very trends that highlight the limitations of conventional tablets and create a fertile ground for innovative alternatives. Mini-tablets are perfectly positioned to capitalize on this demand. While specific market size data for “mini-tablets” as a category is still emerging, we can infer their potential by examining the robust growth of adjacent markets driven by similar needs. For example, the market for Orally Disintegrating Tablets (ODTs), which also addresses swallowing difficulties, is expected to reach over USD 25 billion in 2025 and grow at a CAGR of 8.5%.94 Similarly, the pediatric drugs market is projected to expand at a remarkable CAGR of 12.2%.91 Mini-tablets sit at the intersection of these high-growth segments, poised to capture value by offering a superior solution to the unmet needs that drive them.

Product Differentiation and Life Cycle Management

In a market crowded with “me-too” products and facing the constant threat of generic erosion, meaningful differentiation is the key to sustained commercial success. Mini-tablets provide a powerful platform for creating products that stand out not just on price, but on tangible clinical benefits and user experience.95 A product reformulated as a mini-tablet for pediatric use is not just another version; it is a purpose-built solution for a specific, underserved patient population. A complex cardiovascular therapy consolidated into a single mini-tablet-in-capsule FDC offers a clear advantage in convenience and adherence over taking multiple individual pills.

This capacity for differentiation is most powerfully expressed in the context of Life Cycle Management (LCM). The “patent cliff” is one of the most formidable challenges in the pharmaceutical industry. When a blockbuster drug’s core composition-of-matter patent expires, generic competition can erode up to 90% of its revenue within months.98 A primary goal of LCM is to build a fortress of intellectual property around a drug to extend its commercial life.

Reformulating an existing, successful drug into a novel mini-tablet dosage form is a premier LCM strategy.99 This is not simply a cosmetic change. The new formulation—for example, a controlled-release, taste-masked mini-tablet for once-daily pediatric dosing—is a distinct invention that can be protected by a new set of formulation and method-of-use patents.102 This can extend the product’s market exclusivity for years beyond the expiration of the original patent on the API itself. This strategy, sometimes referred to as “evergreening,” is most robust and defensible when the new formulation provides a clear and demonstrable clinical benefit to patients, a criterion that mini-tablets, with their proven advantages in adherence and safety, readily meet.98

Competitive Intelligence with DrugPatentWatch

To execute these strategies effectively, companies must operate with a clear view of the competitive landscape. In the pharmaceutical industry, patent filings are the tea leaves of future competition, revealing the R&D pipelines and strategic intentions of rivals years before any product reaches the market.104

Systematic monitoring of this landscape is therefore not optional; it is a critical business function. This is where specialized competitive intelligence platforms like DrugPatentWatch become indispensable. By leveraging such a tool, a company can transform the deluge of global patent data into actionable strategic intelligence.67 A dedicated team can set up automated alerts to monitor all new patent filings related to mini-tablet technologies, specific functional coatings, or multiparticulate FDCs. This allows a company to:

- Anticipate Competitor Moves: Identify which rivals are investing in mini-tablet platforms and for which specific drug candidates. This provides an early warning of future competition in a key therapeutic area.

- Identify “White Space” Opportunities: By mapping the existing patent landscape, analysts can identify therapeutic areas or drug classes where mini-tablet formulations have not yet been extensively patented. This “white space” represents a valuable opportunity to be a first-mover and establish a strong, early IP position.

- Inform LCM and Generic Strategy: For a company’s own portfolio, monitoring can reveal when a competitor’s blockbuster drug is approaching its patent cliff, creating an opportunity to develop a differentiated generic product using a mini-tablet formulation. Conversely, it can inform the defensive patenting strategy for a company’s own key assets.

This leads to a more profound understanding of the strategic power of this dosage form. Mini-tablets are not just a target for a single type of patent; they can be the centerpiece of a multi-layered and highly defensible patent portfolio. A single new mini-tablet product could be protected by a “patent thicket” comprising claims on the unique manufacturing process (e.g., specific parameters for low-force compression), the novel blend of excipients used, the specific multi-layer functional coating that achieves a unique release profile, and the particular combination of different mini-tablets within a single capsule.102 This creates a formidable barrier to entry. Offensively, it secures long-term market exclusivity for the innovator. Defensively, the sheer complexity of this interwoven IP makes it exceptionally difficult, time-consuming, and expensive for a generic competitor to successfully challenge the patents or design a non-infringing alternative. This multi-faceted patentability is arguably the most compelling long-term commercial advantage of adopting the mini-tablet platform.

The Future is Small and Smart: Innovations on the Horizon

The evolution of the mini-tablet is far from over. As a versatile platform technology, it is perfectly positioned to converge with two of the most disruptive trends in modern medicine: personalized manufacturing and digital health. The innovations on the horizon promise to move beyond simply improving existing therapeutic models and toward creating entirely new ones, where medications are not just mass-produced but are tailored, tracked, and integrated into a connected ecosystem of patient care.

3D Printing: The Dawn of N-of-1 Manufacturing

For decades, pharmaceutical manufacturing has been defined by economy of scale, producing millions of identical tablets to serve a mass market. 3D printing (or additive manufacturing) represents a fundamental shift towards an economy of one, enabling the on-demand creation of customized medications tailored to the specific needs of an individual patient.108 The FDA’s approval of the first 3D-printed drug, SPRITAM® (levetiracetam), a rapidly dissolving tablet for epilepsy, validated the technology’s viability for commercial use.110

The core concept of mini-tablets as discrete “dose pixels” aligns perfectly with the layer-by-layer approach of 3D printing. The future could see 3D printers installed directly in hospital or community pharmacies—a model known as point-of-care manufacturing.110 A physician could prescribe a precise, non-standard dose of a medication, and the pharmacist could use a 3D printer to fabricate a single dosage form (perhaps a larger, dissolvable carrier tablet) containing the exact number of embedded mini-tablets needed to achieve that dose. This technology could also be used to print “polypills” with complex geometries, combining multiple drugs and release profiles into a single, intricate structure.109 This would revolutionize the treatment of rare pediatric diseases, where dosing is highly specific, and the management of complex polypharmacy in the elderly, eliminating the need for manual pill-splitting or reliance on imprecise liquid formulations.

The Connected Capsule: Integration with Digital Health

The second major frontier is the integration of drug delivery with digital health technologies. The emergence of “smart pills” or “digital pills”—pharmaceutical dosage forms containing ingestible electronic sensors—has opened the door to objectively monitoring medication adherence and gathering physiological data from within the GI tract.111 The first such product approved by the FDA, Abilify MyCite, combines the antipsychotic drug aripiprazole with a sensor that, upon contact with stomach fluid, sends a signal to a wearable patch, which then relays the information to a smartphone app.111

Mini-tablets provide the ideal vehicle for this technology, particularly for complex regimens. A single capsule could be filled with a combination of standard therapeutic mini-tablets and one or more “sensor” mini-tablets. This would allow for the unobtrusive monitoring of adherence to a multi-drug polypill, providing physicians with unprecedented insight into a patient’s medication-taking behavior.

This data stream becomes even more powerful when it is integrated into a broader Digital Therapeutics (DTx) ecosystem.112 The information from the connected capsule could be fed directly into a patient’s health app or a clinician’s electronic health record dashboard.113 This creates a closed-loop system of care. For example, a missed dose detected by the sensor could automatically trigger a reminder notification on the patient’s phone. A pattern of non-adherence could alert a nurse or pharmacist to reach out to the patient to address potential barriers. Data on physiological responses (e.g., from a sensor measuring pH or temperature) could be correlated with the timing of drug release to optimize therapy.111

This convergence of a sophisticated drug delivery platform with a continuous data feedback loop represents the ultimate strategic evolution for the pharmaceutical industry. It marks a fundamental shift in the business model, moving away from simply “selling pills” and towards “selling verifiable health outcomes.” In a future dominated by value-based healthcare, payers like insurance companies and government health systems will increasingly demand evidence that the therapies they reimburse are actually working. A pharmaceutical company that can provide a “smart” mini-tablet system is not just offering a drug; it is offering a comprehensive disease management solution. They can use the objective data generated by the system to prove superior adherence, demonstrate better clinical outcomes, and justify a premium value proposition. This transforms the company from a mere manufacturer of molecules into a true partner in health, delivering not just medicine, but measurable, data-driven results.

Conclusion and Strategic Outlook

The mini-tablet is far more than a diminutive curiosity; it is a powerful and versatile platform technology that is fundamentally reshaping the landscape of oral drug delivery. By deconstructing the monolithic tablet into a multiparticulate system, it unlocks a cascade of benefits that address some of the most persistent challenges in modern pharmacotherapy. It offers a definitive solution to the problem of dysphagia, dramatically improving medication acceptability and adherence in vulnerable pediatric and geriatric populations. Its predictable pharmacokinetic profile enhances safety by reducing plasma concentration fluctuations and mitigating the risk of dose dumping, potentially enabling the oral delivery of drugs with narrow therapeutic indices.

From a manufacturing perspective, mini-tablets leverage established tableting principles while demanding a higher level of precision and control, a challenge that is being met by specialized multi-tip tooling and the adoption of Process Analytical Technology (PAT). This modern approach to quality assurance is not only improving product consistency but is also paving the way for more agile and efficient supply chains through continuous manufacturing.

Commercially, mini-tablets are a strategic powerhouse. They provide a robust platform for product differentiation based on tangible clinical benefits, moving beyond simple price competition. They are a premier tool for intelligent life cycle management, allowing companies to create new, patent-protected value-added medicines from established APIs. And as we look to the future, the mini-tablet platform is poised to converge with 3D printing and digital health, heralding a new era of truly personalized and connected medicine.

For the pharmaceutical leader, the message is clear: embracing mini-tablet technology is not merely a tactical formulation choice. It is a strategic business decision. It is an investment in patient-centricity, a commitment to manufacturing excellence, and a pathway to creating differentiated, high-value products that can secure a competitive advantage in an increasingly complex and demanding healthcare environment. The revolution may be small in scale, but its impact will be anything but.

Key Takeaways

- Platform Technology, Not Just a Pill: Mini-tablets are best understood as a versatile “building block” technology. A single bulk batch can be used to create multiple dosage strengths and product presentations (capsules, sachets), enabling agile, “make-to-order” supply chains.

- Solves Critical Adherence Barriers: They are a proven solution for pediatric and geriatric patients with swallowing difficulties (dysphagia), showing high acceptability and often superiority to liquid formulations. This directly addresses a primary cause of treatment failure in vulnerable populations.

- Superior Pharmacokinetic Profile: As a multiparticulate system, mini-tablets offer more predictable gastric emptying and smoother drug absorption. This reduces peak plasma concentration (Cmax) fluctuations, lowering the risk of side effects and eliminating the danger of “dose dumping” associated with single-unit controlled-release tablets.

- Enables Advanced Combination Therapy: Mini-tablets allow for the combination of multiple, even incompatible, APIs in a single capsule. This facilitates the creation of sophisticated fixed-dose combinations and multi-phasic release systems (e.g., immediate + sustained release) that are difficult to achieve with other dosage forms.

- Powerful Tool for Life Cycle Management: Reformulating an existing drug into a mini-tablet dosage form is a highly effective strategy to extend market exclusivity. The new formulation provides clear clinical benefits and can be protected by a new “thicket” of formulation and method-of-use patents.

- Requires a Quality by Design (QbD) Approach: Successful manufacturing demands an integrated approach, aligning formulation properties (e.g., powder flow, low-force compressibility) with the requirements of specialized multi-tip tooling.

- PAT is a Key Enabler: Process Analytical Technology (PAT), particularly NIR spectroscopy for blend uniformity, is critical for ensuring the high level of quality and consistency required. PAT is the gateway to real-time release testing and continuous manufacturing.

- Future-Ready for Personalization and Digital Health: The mini-tablet concept is perfectly aligned with future trends like 3D printing for point-of-care manufacturing and integration with ingestible sensors to create “smart” pills for monitoring adherence and connecting with digital therapeutic platforms.

Frequently Asked Questions (FAQ)

1. Beyond pediatrics and geriatrics, what is the most promising “niche” therapeutic area for a first-mover to leverage mini-tablet technology?

One of the most promising niche areas is the oral delivery of Narrow Therapeutic Index (NTI) drugs. These are compounds where the margin between a therapeutic and a toxic dose is very small, such as certain anti-epileptics, anti-arrhythmics, or immunosuppressants (e.g., tacrolimus). Conventional tablets often exhibit high pharmacokinetic variability, making it risky to use these drugs orally. Mini-tablets, by providing a more predictable and smoother absorption profile with lower Cmax fluctuations, can significantly improve the safety and reliability of NTI drugs. A company that reformulates an existing NTI drug (or rescues one from the pipeline) into a mini-tablet platform could create a best-in-class product with a powerful safety-based value proposition, capturing a significant market share.

2. What is the biggest misconception about the cost-benefit analysis of switching from a monolithic tablet to a mini-tablet formulation for life cycle management?

The biggest misconception is focusing solely on the higher per-unit manufacturing cost. While it is true that producing mini-tablets requires a greater initial investment in specialized tooling (multi-tip punches) and potentially more complex processes, this view is shortsighted. The true cost-benefit analysis must be holistic. The “benefit” side includes: 1) extended market exclusivity from new formulation patents, which can be worth billions in revenue; 2) the ability to command a premium price for a value-added, patient-centric product; 3) reduced development costs for line extensions, as one bulk batch can create multiple strengths; and 4) lower supply chain costs due to reduced inventory and waste. When viewed through this strategic lens, the higher manufacturing cost is often a small price to pay for years of additional patent-protected revenue and a stronger market position.

3. How can a company use PAT data from mini-tablet manufacturing not just for quality control, but also to build a stronger regulatory submission and a more defensible patent portfolio?

Process Analytical Technology (PAT) data provides a deep, science-based understanding of the manufacturing process. This data can be leveraged strategically in several ways. For a regulatory submission, presenting extensive PAT data (e.g., from in-line NIR monitoring of blend uniformity) demonstrates a high degree of process control and understanding to agencies like the FDA and EMA. This can facilitate the approval of a wider “design space,” giving the company more operational flexibility post-approval and potentially accelerating the review process. For a patent portfolio, the insights gained from PAT can become the basis for new, highly defensible process patents. For example, a company could patent the specific process parameters (e.g., feeder speed, turret RPM) discovered through PAT that are critical for achieving content uniformity for a particularly difficult-to-formulate mini-tablet. This makes it much harder for a generic competitor to replicate the product, as they would have to invent a completely different, non-infringing process to achieve the same quality attributes.

4. What are the key organizational changes required to successfully integrate the development of a “smart” mini-tablet system that combines formulation science with digital health?

Successfully developing a “smart” mini-tablet system requires breaking down traditional organizational silos. Key changes include: 1) Creating Cross-Functional “Pod” Teams: Development can no longer be sequential (formulation, then device, then software). It requires integrated teams from day one, comprising formulation scientists, device engineers (for the sensor/capsule), software developers (for the app/platform), data scientists, regulatory experts familiar with both drugs and medical devices, and commercial teams. 2) Investing in New Talent: The company will need to hire or partner to acquire expertise in areas like electrical engineering, data security, user interface (UI/UX) design, and digital health regulations. 3) Adopting an Agile Development Mindset: Unlike traditional, linear drug development, digital product development is iterative. The organization must adopt agile methodologies that allow for rapid prototyping, user feedback, and continuous improvement of the digital components. 4) Shifting the Commercial Model: The sales and marketing teams must be retrained to sell a comprehensive health solution and engage in value-based discussions with payers, rather than just detailing a drug to physicians.

5. From a competitive intelligence perspective using a tool like DrugPatentWatch, what is a key “red flag” in a competitor’s patent filing that indicates they are developing a disruptive mini-tablet platform?

A key “red flag” or, more accurately, a strong strategic signal, would be the filing of a cluster of interconnected patents around a single API, rather than just one isolated patent. An analyst using a platform like DrugPatentWatch should look for a competitor filing for: 1) a formulation patent on a specific mini-tablet blend; 2) a process patent on a unique manufacturing method for that blend using multi-tip tooling; 3) a method-of-use patent for that mini-tablet in a specific population (e.g., pediatrics); AND 4) a patent on a fixed-dose combination that includes that mini-tablet as a component. This pattern indicates they are not just developing a single product, but a comprehensive, multi-layered platform strategy. It suggests they are building a “patent thicket” to lock down the asset for the long term and are planning for multiple line extensions from a single core technology, signaling a deep strategic commitment to the mini-tablet platform.

References

- Rajapakshe, S. (n.d.). Presentation Slides. University of Maryland School of Pharmacy. 5

- Ilhan, E., Ugurlu, T., & Kerimoglu, O. (2017). Mini Tablets: A Short Review-Revision. Organic & Medicinal Chemistry International Journal, 3(1). 1

- Manne, A. (2019). Development and Characterization of Mini-Tablets with a Focus on the Paediatric Population [Master’s thesis, Uppsala University]. DiVA portal. 2

- Anonymous. (2024). Mini-Tablets as a Pharmaceutical dosage form: A Comprehensive Review. YMER, 23(08). 32

- Ilhan, E., Ugurlu, T., & Kerimoglu, O. (2017). Mini Tablets: A Short Review-Revision. Peertechz Journal of Medical Chemistry and Research, 3(1), 012-022. 3

- Al-Zoubi, N., et al. (2018). Mini-tablets: An approach for treatment of pediatrics and geriatrics. International Journal of Pharmaceutical and Medicinal Research, 6(1). 4

- Anonymous. (n.d.). Mini-Tablets as Multiple Unit Dosage Forms: A Review. Global Research Online. 7

- ResearchGate. (n.d.). Main advantages and disadvantages of mini-tablets.. 14

- Aleksovski, A., et al. (2015). Mini-tablets: a contemporary system for oral drug delivery in targeted patient groups. Expert Opinion on Drug Delivery, 12(1), 65-84. 34

- IMA. (n.d.). Comparison of minitablets and pellets as multiparticulate drug delivery systems for controlled drug release. 118

- Pharma Excipients. (n.d.). Multiparticulates Drug Delivery. 59

- Stoltenberg, I., & Breitkreutz, J. (2023). Comparison of Minitablets and Pellets as Multiparticulate Drug Delivery Systems for Controlled Drug Release. Molecules, 28(21), 7373. 36

- Anonymous. (2019). Mini Tablet- A Multiple Unit Dosage Form. International Journal of Science and Research, 8(9). 27

- Contract Pharma. (n.d.). Multi-particulate Formulations – Tablets or Capsules? 24

- Miyazaki, S., et al. (2022). Comparative acceptability of mini-tablets, fine granules, and liquid formulations in young children: An exploratory randomized crossover study. ResearchGate. 23

- Syed, A. A., & Pingale, P. L. (2016). Mini-Tablet: A Review. American-based Research Journal, 7(2). 8

- USP-NF. (n.d.). Pharmaceutical Dosage Forms. 119

- Al-Tabakha, M. M., et al. (2022). A Review on Hard-Shell Capsules from a Pharmaceutical and Engineering Perspective. PMC. 6

- Mayo Clinic. (n.d.). Griseofulvin (Oral Route). 18

- AdhereTech. (n.d.). Improving Pediatric Medication Adherence with Play-Based Techniques. 31

- Klingmann, V., et al. (2013). Acceptance of uncoated mini-tablets in young children: Results from a prospective exploratory cross-over study. ResearchGate. 15

- Mayo Clinic. (n.d.). Ibuprofen (Oral Route). 120

- Spomer, N., et al. (2022). Mini-Tablets: A Valid Strategy to Combine Efficacy and Safety in Pediatrics. PMC. 30

- Maniruzzaman, M., et al. (2017). Feasibility of mini-tablets as a flexible drug delivery tool. ResearchGate. 10

- DrugPatentWatch. (2024). Mini-Tablets: Revolutionizing Pharmaceutical Dosage Forms. 9

- Spomer, N., et al. (2022). Mini-Tablets: A Valid Strategy to Combine Efficacy and Safety in Pediatrics. Bohrium. 19

- Spomer, N., et al. (2022). Mini-Tablets: A Valid Strategy to Combine Efficacy and Safety in Pediatrics. MDPI. 20

- Maniruzzaman, M., et al. (2017). Feasibility of mini-tablets as a flexible drug delivery tool. PubMed. 65

- Vithani, K., et al. (2024). Fixed-Dose Combination Products: Formulation Strategies, Regulatory Pathways, and the Role of Biopharmaceutics in Development. MDPI. 60

- Susa, S., & Preuss, C. V. (2023). Pharmacokinetics. StatPearls Publishing. 26

- Tothfalusi, L., & Endrenyi, L. (2003). Estimation of Cmax and Tmax in Populations After Single and Multiple Drug Administrations. ResearchGate. 66

- Tsiros, P. K., et al. (2024). Average Slope as a Metric of Absorption Rate in Bioequivalence Studies: A Machine Learning Approach. MDPI. 121

- Science.gov. (n.d.). pharmacokinetic parameters cmax. 122

- de Oliveira, G. G. G., et al. (2022). Development of Melatonin Mini-Tablets with Modulated Release for the Treatment of Sleep Disorders in Children on the Autism Spectrum. PMC. 33

- Vervaet, C., et al. (2015). Extrusion-spheronisation of pharmaceutical products: comparison and industrial scaling-up of extrusion processes by a design of experiments approach. ResearchGate. 35

- Stoltenberg, I., & Breitkreutz, J. (2023). Comparison of Minitablets and Pellets as Multiparticulate Drug Delivery Systems for Controlled Drug Release. MDPI. 36

- Crystal Pharmatech. (n.d.). Pediatric Formulation Mini-Tablet. 123

- European Pharmaceutical Review. (n.d.). The scope of PAT in real-time advanced control of tablet quality. 48

- ISPE. (2020). Quality & Regulatory Solutions for PAT in Continuous Manufacturing. Pharmaceutical Engineering. 45

- Fette Compacting. (n.d.). Tableting tools. 37

- Korsch America. (n.d.). Homepage. 38

- Elizabeth Companies. (n.d.). Tablet Press Parts and Services. 39

- Spomer, N., et al. (2022). Mini-Tablets: A Valid Strategy to Combine Efficacy and Safety in Pediatrics. ResearchGate. 21

- Mistry, P., et al. (2023). Acceptability, Swallowability, and Palatability of Multiple, Film-Coated, 3 mm Placebo Mini-Tablets in Children Aged ≥2–<7 Years. MDPI. 16

- Miyazaki, S., et al. (2022). Comparative Acceptability of Minitablets, Fine Granules, and Liquid Formulations in Young Children: An Exploratory Randomized Crossover Study. MDPI. 11

- Pharmaceutical Journal. (n.d.). Diagnosis and management of dementia. 124

- UPMC. (n.d.). Aging-Related Clinical Trials. 125

- Mayo Clinic. (n.d.). Progesterone (Oral Route). 126

- ResearchGate. (2022). Tablets in Capsule as Strategy to Improve Adherence in Patients Cardiovascular Disease. 61

- Ilhan, E., Ugurlu, T., & Kerimoglu, O. (2017). Mini Tablets: A Short Review-Revision. Chemisgroup. 1

- Liu, Y., et al. (2024). Cardiotoxicity of Small-Molecule Kinase Inhibitors in Cancer Therapy. PMC. 75

- FDA. (n.d.). E11 Clinical Investigation of Medicinal Products in the Pediatric Population.. 28

- Precision for Medicine. (n.d.). FDA Guidance on Pediatric Drug Development. 83

- FDA. (2023). Pediatric Drug Development Under the Pediatric Research Equity Act and the Best Pharmaceuticals for Children Act: Scientific Considerations.. 84

- European Medicines Agency. (n.d.). Scientific guidelines: paediatrics. 29

- Therapeutic Goods Administration. (2024). Guideline on pharmaceutical development of medicines for paediatric use. 86

- GMP Compliance. (n.d.). EMA: New Guideline on Development of Medicines for Paediatric Use. 85

- Market Research Future. (n.d.). Kids Tablet Market. 127

- Accio. (n.d.). Trend of New Mini Tablets. 128

- Allied Market Research. (n.d.). Tablet PC Market. 129

- ZDNet. (n.d.). Best small tablet. 130

- PCMag. (n.d.). The Best Tablets. 131

- DrugPatentWatch. (n.d.). Overcoming Formulation Challenges in Generic Drug Development. 67

- GeneOnline. (2025). DrugPatentWatch.com: Early Patent Integration, Competitive Analysis, and Expert Collaboration Recommended for Pharmaceutical Profit Protection. 107

- ResearchGate. (n.d.). Competitive intelligence and patent analysis in drug discovery. 104