Welcome to the high-stakes world of generic pharmaceuticals. It’s a realm often misunderstood as a simple game of copy-and-paste, a place where innovation takes a backseat to imitation. But ask anyone who has successfully navigated a generic drug from concept to market, and they’ll tell you a different story. It’s a story of precision, strategy, and scientific rigor, where the slightest misstep can mean the difference between a blockbuster success and a multimillion-dollar failure. The heart of this narrative? The clinical study.

For decades, the generic drug industry has been a cornerstone of global healthcare, providing access to affordable medicines and driving down costs for patients and payers alike. The premise is simple: once the patent on an innovative, brand-name drug expires, other manufacturers can produce and sell a chemically identical version. This competition is the engine of affordability. But how do we know the generic version is a trustworthy substitute for the original? How can a physician prescribe, a pharmacist dispense, and a patient ingest a generic medication with the same confidence they have in the brand-name product they’ve known for years?

The answer lies in a specialized, meticulously designed, and flawlessly executed type of clinical trial: the bioequivalence study. This isn’t your typical Phase I-III clinical trial aimed at discovering a new drug’s safety and efficacy. The brand-name drug has already done that heavy lifting, spending billions of dollars and over a decade proving its worth. The generic’s job is different. Its mission is to prove that it is, for all practical purposes, a perfect mirror of the original.

The Shifting Landscape of the Generic Pharmaceutical Industry

The generic market is no longer just about simple pills and capsules. The landscape is evolving at a breakneck pace. We’re seeing a push towards more complex dosage forms: long-acting injectables, transdermal patches, inhalation products, and topical creams. These “complex generics” don’t follow the simple rules of their oral solid counterparts. They present unique scientific and regulatory challenges that demand a higher level of sophistication from the companies that dare to develop them.

Furthermore, regulatory bodies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) are continuously refining their standards. They are demanding more robust data, more sophisticated analytical techniques, and a deeper understanding of drug product performance. The bar is constantly being raised. In this environment, simply “doing” a clinical study isn’t enough. You have to conduct an effective one.

Why “Effective” is the New Watchword in Generic Clinical Studies

What does “effective” even mean in this context? It means more than just getting a passing grade from the regulators. An effective generic drug clinical study is:

- Strategically Aligned: It begins with meticulous market and patent analysis, long before the first volunteer is ever dosed.

- Scientifically Sound: It is built on a robust understanding of the drug’s pharmacology and the specific regulatory requirements for its dosage form.

- Operationally Flawless: It is executed with precision, minimizing variability and eliminating errors that could cloud the results.

- Cost-Efficient: It achieves its objective without unnecessary delays or budget overruns, which can cripple a product’s profitability before it even launches.

In short, an effective study is a competitive advantage. It accelerates your path to market, builds confidence with regulators, and ultimately maximizes your return on investment. A failed or poorly designed study, on the other hand, isn’t just a scientific setback; it’s a strategic disaster, costing precious time and money and giving your competitors a head start.

The Core Objective: Demonstrating Bioequivalence, Not Efficacy

Let’s clarify the fundamental principle. Generic drug studies are not designed to prove that the drug works. That’s already been established by the Reference Listed Drug (RLD), also known as the innovator or brand-name drug. Instead, the goal is to demonstrate bioequivalence (BE).

Bioequivalence means that the generic drug delivers the same amount of active ingredient into a patient’s bloodstream over the same period of time as the brand-name drug. The central hypothesis is that if the drug concentration profiles in the blood are the same, the therapeutic effect at the site of action will also be the same. This is the scientific bridge that allows regulators to extrapolate all the safety and efficacy data from the RLD to the generic product.

This entire article is your comprehensive guide to building that bridge. We will journey through every stage of the process, from the initial strategic decisions made in the boardroom to the final statistical analysis submitted to the FDA. We’ll explore the science, navigate the regulatory hurdles, and uncover the operational best practices that separate the market leaders from the rest of the pack. Whether you’re a seasoned veteran or new to the world of generics, prepare to go beyond the basics and learn how to conduct truly effective generic drug clinical studies.

Laying the Foundation: Pre-Clinical Strategy and Regulatory Intelligence

Before a single milligram of a generic drug is administered to a human subject, a mountain of strategic work must be accomplished. The success of a generic clinical program is often determined long before the study protocol is even written. This foundational phase is about asking the right questions, gathering critical intelligence, and making shrewd decisions that will pave the way for a smooth and successful regulatory submission. Think of it as an architect drafting the blueprints and surveying the land before pouring the concrete. Rushing this stage is a recipe for disaster.

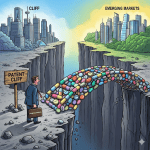

The Critical First Step: Patent Expiry and Market Opportunity Analysis

The journey of any generic drug begins with a date on a calendar: the patent expiry of its brand-name counterpart. This is the starting pistol for the generic race. Identifying these opportunities is both an art and a science, requiring a deep understanding of intellectual property, market dynamics, and competitive strategy.

Leveraging Services like DrugPatentWatch for Competitive Intelligence

How do you stay ahead of the curve? You can’t just wait for patents to expire; you need to anticipate them. This is where strategic intelligence platforms become invaluable. Services like DrugPatentWatch provide comprehensive databases and analytics on drug patents, exclusivity periods, and litigation. They allow companies to:

- Identify upcoming patent cliffs: Pinpoint which blockbuster drugs are losing their market exclusivity and when.

- Analyze the competitive landscape: See which other generic companies are filing Abbreviated New Drug Applications (ANDAs) for the same product. This helps gauge the level of competition you’ll face on day one. A “first-to-file” opportunity with 180 days of market exclusivity is the holy grail, but even being one of the first few to market can be highly lucrative.

- Assess the complexity: Understand the patent landscape. Is it a single, straightforward patent, or a “patent thicket” of multiple, overlapping patents that could lead to costly litigation?

Using these tools, you can build a development pipeline that is not just scientifically feasible but also commercially viable. It’s about placing your bets on the right horses, armed with the best possible data.

Identifying the Right Candidate: Beyond Blockbusters

While targeting billion-dollar blockbusters is tempting, it’s not always the smartest strategy. These products attract a swarm of competitors, leading to rapid price erosion once the market opens. A more nuanced approach involves considering:

- Niche Markets: Are there smaller-market drugs with fewer potential competitors but stable pricing?

- Complex Formulations: Can your company tackle a difficult-to-manufacture product (e.g., a long-acting injectable or a transdermal patch) that will deter less sophisticated players? The barrier to entry is higher, but so are the potential rewards.

- Drug Shortages: Are there opportunities to bring a generic to market to address a persistent drug shortage, creating goodwill with both regulators and healthcare providers?

The ideal candidate sits at the intersection of market opportunity, technical capability, and strategic fit for your company.

Deconstructing the Reference Listed Drug (RLD)

Once you’ve selected your target product, the next critical task is to obtain and thoroughly understand the Reference Listed Drug (RLD). The RLD is your benchmark, your gold standard. Your entire development program is geared towards proving your product is its therapeutic equivalent.

Procuring and Characterizing the RLD: A Logistical Challenge

This might sound simple, but it can be a significant hurdle. You need to procure a sufficient quantity of multiple lots of the RLD directly from the target market (e.g., the U.S. for an FDA submission). This can be expensive and logistically complex. Sometimes, innovator companies may even employ strategies to restrict access to their drug for BE study purposes, a practice the FDA has been actively trying to curb [1].

Once procured, the RLD must be meticulously “de-formulated” or reverse-engineered. This involves a battery of analytical tests to identify:

- The active pharmaceutical ingredient (API) and its physical properties.

- All the excipients (inactive ingredients) and their quantities.

- The critical quality attributes (CQAs) of the dosage form, such as its dissolution profile, particle size, and hardness.

This characterization is the recipe for your own formulation development. Your goal is to create a product that is not just chemically the same but also physically and functionally similar.

Understanding the Q1/Q2/Q3 Sameness for Complex Generics

For more complex products, especially parenteral (injectable), ophthalmic (eye drops), and otic (ear drops) formulations, the FDA requires a demonstration of “sameness.” This is broken down into three levels [2]:

- Q1 (Qualitative Sameness): Your product must contain the same inactive ingredients as the RLD.

- Q2 (Quantitative Sameness): The concentration of each inactive ingredient in your product must be within a certain percentage (typically ±5%) of the RLD.

- Q3 (Physicochemical Sameness): Your product must have the same physicochemical properties, such as pH, viscosity, and physical state (e.g., solution, suspension).

Achieving Q1/Q2/Q3 sameness is a formidable challenge that requires advanced analytical capabilities. However, getting it right can sometimes allow a company to request a waiver for an in-vivo BE study, saving millions of dollars and months of time. This is a prime example of where upfront investment in formulation science pays massive dividends.

Navigating the Global Regulatory Maze: FDA, EMA, and Beyond

The regulatory strategy is not an afterthought; it’s an integral part of the initial planning. While the core principle of bioequivalence is global, the specific requirements can vary significantly between regions. A product developed for the U.S. market may not meet EMA standards without additional work, and vice-versa.

An Introduction to the Abbreviated New Drug Application (ANDA) Pathway

In the United States, generic drugs are approved via the ANDA pathway. An ANDA is essentially a comprehensive dossier of evidence submitted to the FDA’s Office of Generic Drugs (OGD). It doesn’t need to contain preclinical (animal) or large-scale clinical (human efficacy) studies. Instead, it relies on the FDA’s previous finding that the RLD is safe and effective. The core of the ANDA is the Chemistry, Manufacturing, and Controls (CMC) section and, of course, the bioequivalence data.

The FDA provides a wealth of information to guide generic applicants, including product-specific guidances (PSGs) that detail the recommended BE study design for thousands of different drugs. Ignoring these PSGs is a cardinal sin of generic development. They are your roadmap to regulatory approval.

Harmonization Efforts (ICH) and Regional Nuances

The International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) has made great strides in harmonizing many aspects of drug development, such as the format of the submission (the eCTD – electronic Common Technical Document) and the content of the clinical study report (ICH E3).

However, significant regional differences remain, particularly in BE study design and statistical analysis. For example:

- Reference Product: The EMA requires the use of an RLD sourced from within the European Economic Area (EEA), while the FDA requires a U.S.-sourced RLD. This may mean conducting separate studies if you plan to market globally.

- Statistical Analysis: While the general approach is similar, there can be differences in how to handle specific situations, like replicate designs for highly variable drugs.

- Acceptance Criteria: The standard BE acceptance criteria are largely harmonized, but criteria for certain complex or narrow therapeutic index drugs can differ.

A successful global generic company must be fluent in the language of multiple regulatory agencies. This requires a dedicated regulatory intelligence team that can interpret guidance documents, anticipate changes, and design a global development program that is both efficient and compliant.

This foundational stage is where the battle is often won or lost. Strong strategic planning, deep regulatory knowledge, and a thorough understanding of the target product create a solid launchpad for the clinical phase. Neglect this groundwork, and you’re building your house on sand.

Designing the Cornerstone of Your ANDA: The Bioequivalence (BE) Study

With the strategic groundwork laid, we now move to the scientific core of the generic drug approval process: the bioequivalence (BE) study. This is where you generate the pivotal data that will prove your product is a worthy substitute for the brand-name original. The design of this study is not a one-size-fits-all template. It is a carefully considered decision based on the drug’s properties, the dosage form, and specific regulatory guidance. A well-designed study is elegant, efficient, and robust, while a poorly designed one can be a costly, time-consuming detour on the road to approval.

Understanding the Science: Pharmacokinetics (PK) as the Primary Endpoint

The entire concept of bioequivalence for most systemically acting drugs hinges on the field of pharmacokinetics (PK). PK is the study of what the body does to a drug—how it is Absorbed, Distributed, Metabolized, and Excreted (ADME). By measuring the concentration of the drug in the blood (or, more commonly, plasma) over time, we can create a profile that serves as a surrogate for therapeutic activity. If the plasma concentration profile of the generic matches the RLD, we infer that their clinical effects will also match.

Key PK Parameters: Cmax, AUCt, and AUC∞

From the plasma concentration-time curve, we derive several key PK parameters. For most immediate-release oral dosage forms, the regulatory agencies are laser-focused on three primary parameters:

- C_max (Maximum Concentration): This is the highest concentration the drug reaches in the plasma. It’s a measure of the rate of drug absorption. A C_max that is too high could suggest potential toxicity, while one that is too low might indicate the drug isn’t getting absorbed fast enough to be effective.

- AUC_t (Area Under the Curve to the last measurable time point): This is the area under the plasma concentration-time curve from time zero to the last time point where the drug concentration could be reliably measured. It represents the total extent of drug exposure over that time period. Mathematically, it’s the integral of the concentration curve: AUC_t=int_0tC(t)dt.

- AUC_∞ (Area Under the Curve extrapolated to infinity): This parameter represents the total drug exposure from time zero to infinity. It’s calculated by adding the area from the last time point to infinity to AUC_t. This final portion is usually calculated as C_last/k_el, where C_last is the last measured concentration and k_el is the terminal elimination rate constant. Both AUC_t and AUC_∞ are measures of the extent of drug absorption.

The goal of the BE study is to demonstrate that the geometric mean ratios of these key parameters for the test (generic) and reference (RLD) products fall within a pre-specified confidence interval.

The 90% Confidence Interval: The Statistical Hurdle

This is the statistical gateway to approval. To prove bioequivalence, the 90% Confidence Interval (CI) for the ratio of the geometric means (Test/Reference) for C_max, AUC_t, and AUC_∞ must fall entirely within the acceptance limits of 80.00% to 125.00% [3].

Let’s break this down. It doesn’t mean your generic’s average C_max must be within ±20% of the brand. It’s a more rigorous statistical test. The 90% CI represents a range of values within which we are 90% confident the true ratio of the population means lies. By requiring this entire range to be within the 80-125% window, regulators ensure with high probability that the generic and brand products are not meaningfully different in their bioavailability.

Why the asymmetric 80-125% range? This is because the statistical analysis is performed on log-transformed data. In the logarithmic scale, the interval is symmetrical around zero. When you transform it back to the original arithmetic scale, it becomes 80-125%. This transformation is necessary because PK data are typically not normally distributed.

Passing this statistical test is the primary objective of the clinical portion of your ANDA.

Choosing the Right Study Design: A Strategic Decision

The “how” of the study is just as important as the “what.” The study design must be chosen to minimize bias, reduce variability, and answer the bioequivalence question as efficiently as possible.

The Gold Standard: The Two-Way Crossover Design

For most oral, immediate-release drugs with a relatively short half-life, the randomized, two-period, two-sequence, single-dose crossover design is the undisputed gold standard.

Here’s how it works:

- A group of healthy volunteers is randomly assigned to one of two sequences (e.g., Sequence AB or Sequence BA).

- Period 1: Subjects in Sequence AB receive the Test product (A), and subjects in Sequence BA receive the Reference product (B). Blood samples are collected over a set period.

- Washout Period: A sufficient time (typically at least 5-7 half-lives of the drug) is allowed to pass to ensure the drug from Period 1 is completely eliminated from the body.

- Period 2: The subjects “cross over.” Those in Sequence AB now receive the Reference product (B), and those in Sequence BA receive the Test product (A). Blood samples are collected again.

The beauty of this design is that each subject serves as their own control. By comparing the Test and Reference products within the same person, we can eliminate the significant inter-subject variability that comes from differences in metabolism, body weight, and genetics. This makes the study much more powerful and efficient, requiring far fewer subjects than a parallel design.

Parallel Designs: When Crossover Isn’t Feasible

Sometimes, a crossover design just isn’t an option. The most common reason is a drug with a very long half-life. If the washout period would need to be weeks or even months long, the study becomes impractical and the risk of subjects dropping out increases dramatically. In such cases, a parallel group design is used.

In a parallel study, one group of subjects receives only the Test product, and a separate group receives only the Reference product. The comparison is then made between the two groups. The major drawback is that you are no longer controlling for inter-subject variability. As a result, parallel studies require a much larger sample size to achieve the same statistical power as a crossover study, making them more expensive and complex to manage.

Replicate Designs for Highly Variable Drugs (HVDs)

Some drugs naturally exhibit high variability in their absorption, even within the same person. For these Highly Variable Drugs (HVDs), the intra-subject variability for parameters like C_max can be greater than 30%. In a standard crossover study, this high variability would require an enormous number of subjects to narrow the 90% CI to fit within the 80-125% window.

To address this, regulatory agencies like the FDA and EMA have endorsed replicate study designs. In a full replicate design (e.g., a four-period, two-sequence design like TRTR/RTRT), each subject receives the Test product twice and the Reference product twice. This allows for a direct measurement of the within-subject variability for both products.

The key benefit is that if a drug is demonstrated to be an HVD, regulators allow for Reference-Scaled Average Bioequivalence (RSABE) analysis. Under this framework, the acceptance limits for C_max can be widened based on the observed variability of the RLD [4]. This is a pragmatic approach that prevents companies from being penalized for the inherent variability of the drug itself, making the development of generics for HVDs feasible.

Fed vs. Fasting Studies: Mimicking Real-World Conditions

Most BE studies are conducted in healthy volunteers who have fasted overnight. This creates a standardized, low-variability environment to assess the drug’s performance. However, what happens when a patient takes the drug with a meal? Food, especially a high-fat, high-calorie meal, can significantly affect a drug’s absorption. It can delay gastric emptying, alter pH, and interact with the drug formulation.

Therefore, for most modified-release products and for some immediate-release products where a food effect is known or suspected, the FDA requires a food-effect BE study in addition to the fasting study. In these “fed” studies, subjects consume a standardized high-fat breakfast just before taking the drug. The goal is to prove that your generic product and the RLD behave similarly in both the fasted and fed states, ensuring they are interchangeable under real-world conditions.

Subject Selection and Population Dynamics

The people who participate in your study are at its heart. Selecting the right population and ensuring their safety and well-being is paramount, both ethically and scientifically.

Defining the “Healthy Volunteer”: Inclusion and Exclusion Criteria

BE studies are typically conducted in healthy volunteers to minimize variability not related to the drug formulation. The protocol must have meticulously detailed inclusion criteria (what qualifies a subject to participate) and exclusion criteria (what disqualifies them).

- Inclusion Criteria typically include age range (e.g., 18-55 years), a Body Mass Index (BMI) within a normal range (e.g., 18.5-30.0 kg/m²), and a clean bill of health as determined by a medical history, physical exam, ECG, and clinical laboratory tests.

- Exclusion Criteria are extensive and include things like a history of significant diseases (cardiac, renal, hepatic), allergies to the drug class, recent use of other medications, smoking, alcohol or drug abuse, and recent participation in another clinical trial.

These criteria are designed to create a relatively homogenous study population, reducing the “noise” in the PK data.

The Role of Demographics: Age, Gender, and BMI

Regulators generally expect a mix of male and female subjects in BE studies. While historically many studies were conducted only in males, this is no longer the standard unless the drug is only indicated for males. The inclusion of both genders provides a more representative sample of the general population. The distribution should be balanced between the treatment sequences to avoid bias.

For some drugs, specific populations may be required. For example, if a drug is used predominantly in the elderly, a study in that population might be necessary if there’s reason to believe their PK would be different.

Ethical Considerations and the Informed Consent Process

Conducting research on human subjects is a profound responsibility. Every BE study must be reviewed and approved by an Institutional Review Board (IRB) or an Independent Ethics Committee (IEC) before it can begin. The IRB’s role is to protect the rights and welfare of the study participants.

Central to this is the Informed Consent Process. This is not just about getting a signature on a form. It’s a comprehensive discussion between the research staff and the potential subject, ensuring they fully understand:

- The purpose of the study.

- The procedures involved (e.g., number of blood draws, overnight stays).

- The potential risks and benefits of participation.

- The fact that their participation is entirely voluntary and they can withdraw at any time without penalty.

A robust and ethical consent process is the non-negotiable foundation of any clinical trial.

The design phase is a masterclass in balancing scientific rigor, regulatory requirements, and practical feasibility. The choices made here will echo throughout the execution of the study and will ultimately be scrutinized by regulators under a microscope. Getting it right is the single most important step toward a successful ANDA submission.

The Devil is in the Details: Executing Flawless Clinical Operations

You can have the most brilliant study design and the most promising formulation, but if the clinical execution is sloppy, your entire program can crumble. The operational phase of a generic drug study is a complex ballet of logistics, communication, and meticulous attention to detail. Every blood sample, every dose administered, and every piece of data recorded must be handled with unwavering precision. This is where theory meets reality, and even the smallest deviation can have significant consequences.

Site Selection and Management: Your Partners in Success

For most generic companies, the actual clinical conduct of the study is outsourced to a Clinical Research Organization (CRO), often called a “Phase I unit” or “clinical site.” This is arguably the most important partnership in your development program. Choosing the right CRO is not a matter of simply picking the lowest bidder; it’s a critical due diligence process.

“The relationship between a sponsor and a CRO is a true partnership. A sponsor should not view the CRO as a mere vendor, but as an extension of their own team. Proactive communication, mutual respect, and a shared commitment to quality are the cornerstones of a successful collaboration that can navigate the inevitable challenges of clinical research.” — Dr. Jean-Claude Tardif, Director, Montreal Heart Institute Research Centre [5]

Qualifying a Clinical Research Organization (CRO): A Due Diligence Checklist

Before signing a contract, you need to conduct a thorough qualification audit of potential CROs. Your checklist should include:

- Experience: Have they conducted BE studies for this type of drug or dosage form before? Do they have a strong track record with the relevant regulatory agency (e.g., FDA, EMA)? Ask to see their inspection history.

- Facilities and Equipment: Is the clinical facility clean, well-organized, and adequately equipped? Are the beds, infusion pumps, and emergency equipment up to standard? Is their pharmacy secure and properly controlled?

- Personnel: Meet the key people who will be working on your study. Are the Principal Investigator (PI), clinical staff, and project managers experienced and knowledgeable? Gauge their responsiveness and communication style.

- Standard Operating Procedures (SOPs): Review their SOPs for critical processes like informed consent, dosing, sample collection, and handling of adverse events. Are they comprehensive and clear?

- Quality Management System (QMS): Do they have a robust QMS in place? How do they handle deviations, corrective and preventive actions (CAPAs), and internal audits?

- Recruitment Capabilities: Do they have a reliable database of healthy volunteers? What are their recruitment strategies and average timelines?

Investing time in this upfront qualification process can save you from a world of pain down the line.

Building a Collaborative Relationship for Proactive Problem-Solving

Once you’ve selected your CRO, the work has just begun. The key to a smooth study is not the absence of problems—problems will always arise—but the ability to address them quickly and effectively. This requires a collaborative, not adversarial, relationship.

- Clear Communication Channels: Establish a clear communication plan from the outset. Who are the key contacts on both sides? How often will you have status meetings?

- Sponsor Oversight: While you’ve outsourced the work, you haven’t outsourced the responsibility. Your clinical operations team should be actively involved. This means reviewing data in near real-time, being available to answer questions, and perhaps even having a monitor on-site during critical study periods.

- Shared Goals: Ensure the CRO understands not just the “what” of the protocol, but the “why.” When they understand the strategic importance of certain procedures, they are more likely to execute them with the required diligence.

The Clinical Protocol: The Blueprint for Your Study

The clinical protocol is the single most important document for the study. It is the detailed instruction manual that every member of the clinical and bioanalytical team will follow. It must be unambiguous, comprehensive, and scientifically sound. A well-written protocol is your best defense against confusion and error during study conduct.

Essential Components of a Robust BE Protocol

An ICH-compliant protocol will be a lengthy document, but some of the most critical sections include:

- Study Objectives: Clearly state the primary and any secondary objectives (e.g., to compare the rate and extent of absorption of a test and reference product).

- Study Design: Detail the design chosen (e.g., crossover, parallel), dosing regimen, periods, and washout duration.

- Inclusion/Exclusion Criteria: The comprehensive list discussed in the previous section.

- Treatment Plan: Specify the exact products to be administered, the dose, the route, and the randomization scheme.

- Study Procedures: This is the play-by-play. It includes the schedule of events from check-in to check-out, with precise timing for dosing, meal times, and, most importantly, the blood sampling schedule (e.g., pre-dose, 0.5, 1, 1.5, 2, 3, 4, 6, 8, 12, 24 hours post-dose).

- Safety and Adverse Event (AE) Monitoring: How will AEs be collected, assessed for severity and causality, and reported? What are the procedures for handling a medical emergency?

- Pharmacokinetic Sample Handling: Specify the type of collection tube (e.g., K2-EDTA), centrifugation requirements (speed and temperature), plasma harvesting technique, storage conditions (e.g., -20°C or -70°C), and labeling instructions.

- Statistical Methods: Outline the PK parameters to be calculated, the statistical model to be used (e.g., ANOVA on log-transformed data), and the bioequivalence acceptance criteria.

The protocol must be reviewed and approved by both the sponsor and the CRO, and most importantly, by the IRB/IEC before any study activities can begin.

Avoiding Protocol Deviations: Training, Monitoring, and Communication

A protocol deviation is any departure from the instructions laid out in the protocol. While minor deviations are common, major or systemic deviations can jeopardize the integrity of the study data and even lead to the FDA rejecting the study.

The keys to minimizing deviations are:

- Thorough Training: Before the study starts, hold a “site initiation visit” or kick-off meeting to train all clinical staff on the specifics of your protocol. Don’t assume they’ll just “read it and get it.” Walk them through every critical procedure.

- Clear Source Documents: The case report forms (CRFs) or source documents where data is recorded must be well-designed and easy to use, mirroring the flow of the protocol.

- Proactive Monitoring: A Clinical Research Associate (CRA) or monitor should be regularly reviewing the study data as it’s being generated to catch potential issues early.

Pharmacy Operations and Drug Accountability

The clinical site’s pharmacy is the nerve center for the investigational products. They are responsible for receiving, storing, dispensing, and tracking every single dose of both the Test and Reference products.

Blinding and Randomization Procedures

To prevent bias, BE studies should be conducted in a double-blind manner whenever possible. This means that neither the subjects nor the study staff knows who is receiving the Test product and who is receiving the Reference product. This requires the two products to be “over-encapsulated” or manufactured to be identical in appearance.

The pharmacy is responsible for managing the randomization code, which links each subject number to the treatment sequence. This code is only broken at the end of the study, after the bioanalytical data is finalized.

If blinding is not possible (e.g., due to obvious differences in the products that cannot be masked), a single-blind design (where the subject is blinded but the staff is not) may be used. In this case, it’s critical to have procedures in place to minimize the risk of operational bias.

Meticulous Management of Test and Reference Products

The pharmacy must maintain pristine records for drug accountability. This means tracking:

- Receipt of the products from the sponsor.

- Storage conditions (e.g., temperature logs).

- Dispensing of each dose to each subject.

- Return of any unused product.

- Final reconciliation of all doses.

This chain of custody documentation is a key part of the study’s audit trail and will be scrutinized by regulatory inspectors.

Sample Collection, Processing, and Bioanalysis: The Moment of Truth

This is where the rubber meets the road. All the planning and execution up to this point culminate in a series of small tubes of plasma. The integrity of these samples is non-negotiable.

The Bioanalytical Method Validation: Precision, Accuracy, and Stability

Before the first study sample can be analyzed, the laboratory (which may be part of the CRO or a separate specialized lab) must develop and fully validate the analytical method used to measure the drug concentration in plasma. This is a rigorous, multi-step process governed by FDA and ICH guidelines [6]. The validation proves that the method is:

- Accurate: It measures the correct concentration.

- Precise: It gives repeatable results.

- Selective: It can measure the drug without interference from other substances in the plasma.

- Sensitive: It can detect the drug down to the lowest required concentration (the Lower Limit of Quantification or LLOQ).

- Stable: The drug doesn’t degrade in the plasma samples during collection, processing, storage, or analysis (this includes freeze-thaw stability, short-term bench-top stability, and long-term storage stability).

This validation report is a critical component of the ANDA submission.

Ensuring Sample Integrity from Vein to Vial to Analysis

A perfect analytical method is useless if the samples are compromised. A breakdown in the sample lifecycle can invalidate the entire study.

- Collection: Were the samples drawn at the correct times? Was the correct type of tube used? Were they immediately placed on ice?

- Processing: Were the samples centrifuged at the right speed and temperature? Was the plasma harvested without contamination?

- Labeling: Is every single aliquot labeled clearly and correctly with the subject number, time point, and study ID? A single mislabeled sample can cause havoc.

- Storage and Shipping: Were the samples stored at the correct temperature (e.g., -70°C) at all times? If shipped, were they sent on sufficient dry ice with temperature monitors to prove the cold chain was not broken?

Every step must be documented meticulously. This chain of custody ensures that the concentration value reported by the lab can be traced back to a specific subject at a specific time point, giving regulators confidence in the final data.

The operational phase is a testament to the fact that in clinical research, excellence is not an act but a habit. It is the sum of hundreds of small tasks performed correctly, consistently, and with an unwavering focus on quality.

Beyond Standard BE: Tackling Complex Generics and Special Cases

The world of generics is expanding far beyond the familiar territory of immediate-release tablets and capsules. The next frontier of opportunity lies in complex generics. These are products that are inherently more difficult to develop and, crucially, to prove equivalent to their brand-name counterparts. This complexity might stem from the formulation, the delivery device, the route of administration, or a combination of these factors.

Successfully navigating the development of complex generics requires a deeper scientific understanding, more sophisticated analytical tools, and often, more intricate clinical study designs. For these products, a simple blood draw and PK analysis may not be enough to tell the whole story. Regulators demand a more comprehensive “totality of evidence” approach to ensure substitutability.

Locally Acting Drugs: When PK Isn’t the Whole Story

Many drugs are not designed to be absorbed into the bloodstream to have their effect. They act locally, right where they are applied. Think of a corticosteroid cream for a skin rash, an asthma inhaler that delivers medicine to the lungs, or eye drops for glaucoma. For these drugs, measuring the concentration in the blood is often irrelevant or impossible, as the levels are typically very low or non-existent. So, how do we establish bioequivalence? We have to get creative and measure the drug’s effect where it matters most.

Dermatological Products: Vasoconstrictor Assays and Dermal PK

For potent topical corticosteroids, the classic approach is the vasoconstrictor assay (VCA). This is a pharmacodynamic (PD) study, meaning it measures the drug’s effect on the body rather than its concentration.

The principle is simple: corticosteroids cause the capillaries in the skin to constrict, leading to skin blanching or whitening. In a VCA, small amounts of the test, reference, and placebo creams are applied to designated sites on the forearms of healthy volunteers. The degree of skin blanching is then visually scored by trained assessors at various time points. By plotting the blanching score over time, you can create a PD response curve. Bioequivalence is established if the response curves for the test and reference products are statistically equivalent [7].

More recently, for some topical products, the FDA has started accepting studies that use newer techniques like dermal open-flow microperfusion or tape stripping to measure the drug concentration directly within the layers of the skin (dermal PK). This provides a more direct measure of local bioavailability but comes with its own set of technical challenges.

Inhaled and Nasal Products: Particle Size Distribution and In Vitro-In Vivo Correlations (IVIVC)

For orally inhaled and nasal drug products (OINDPs), such as metered-dose inhalers (MDIs) for asthma or nasal sprays for allergies, proving equivalence is a multi-faceted challenge. It’s not just about the drug; it’s about the drug-device combination. A generic must not only have the same active ingredient but must also deliver it to the lungs or nasal passages in the same way as the brand.

The regulatory pathway for these products is a textbook example of the “totality of evidence” approach:

- In Vitro Equivalence: This is the foundation. Extensive laboratory testing must prove that the generic product has equivalent physical and performance characteristics, including:

- Aerodynamic Particle Size Distribution (APSD): This is critical. The size of the particles determines where in the respiratory tract they will deposit. You must prove your device generates a particle cloud with the same size profile as the RLD.

- Spray Pattern and Plume Geometry: For nasal sprays, these characteristics must be equivalent.

- Dose Content Uniformity: Every puff or spray must deliver a consistent dose.

- Pharmacokinetic (PK) Studies: If the drug is systemically absorbed to a significant degree, a standard PK bioequivalence study is still required to assess the portion of the dose that enters the bloodstream.

- Pharmacodynamic (PD) or Clinical Endpoint Studies: For some products, particularly those where systemic absorption is low (like inhaled corticosteroids), a clinical study may be required. This could be a PD study (e.g., measuring bronchodilation in asthma patients) or a comparative clinical endpoint study to demonstrate equivalent therapeutic effect.

Establishing an In Vitro-In Vivo Correlation (IVIVC) can be a powerful tool here. If you can develop a mathematical model that reliably predicts the in vivo PK performance based on in vitro data (like the dissolution or particle size), you might be able to use in vitro data to support certain post-approval changes without needing another expensive clinical trial.

Modified-Release Formulations: The Challenge of Matching the Release Profile

Modified-release (MR) products, such as extended-release (ER) or delayed-release (DR) tablets, are designed to release the drug over a prolonged period or in a specific part of the gastrointestinal tract. This offers benefits like less frequent dosing and more stable plasma concentrations. However, for a generic, mimicking the complex release mechanism of the brand-name product is a significant formulation and clinical challenge.

Designing Multi-Dose and Steady-State Studies

While a single-dose study is sufficient for immediate-release products, it doesn’t tell the full story for MR formulations. With MR drugs, concentrations build up over several days of dosing. Therefore, regulators often require a multiple-dose, steady-state bioequivalence study.

In this design, subjects take the drug (either Test or Reference) once or twice daily for several days until the drug reaches steady state. Steady state is the point at which the rate of drug administration is equal to the rate of elimination over a dosing interval, resulting in a stable plateau of concentrations. Once steady state is achieved, intensive PK blood sampling is conducted over a full dosing interval (e.g., 24 hours for a once-daily drug).

The key BE metrics at steady state are:

- C_max,ss: The maximum concentration at steady state.

- C_min,ss: The minimum or trough concentration at steady state.

- AUC_τ: The area under the curve over one dosing interval (τ) at steady state.

These parameters must all meet the 80-125% acceptance criteria.

The Importance of Food-Effect Studies for MR Products

Food-effect studies are even more critical for MR products than for immediate-release ones. A high-fat meal can dramatically alter the release profile of an MR formulation. In a worst-case scenario known as “dose dumping,” the presence of food could cause the tablet or capsule to release its entire drug load all at once. This would turn an extended-release product into a dangerous, high-dose immediate-release product, leading to a massive spike in drug concentration (C_max) and potential toxicity.

Therefore, fed-state BE studies are almost always mandatory for MR generics. You must prove that your formulation is just as robust and reliable as the brand-name product, even when taken with a meal. The study design is similar to the fasting study, but subjects consume a standardized high-fat meal just before dosing. Demonstrating bioequivalence in both the fed and fasting states provides the confidence that the generic MR product is truly interchangeable.

The Rise of Generic Biologics: Biosimilars

Perhaps the most complex and rapidly evolving area is that of biosimilars. Biologics (or biopharmaceuticals) are large, complex molecules—like proteins or monoclonal antibodies—produced in living systems. They are fundamentally different from small-molecule chemical drugs. Because they are produced in cell lines and are so large and complex, it’s impossible to create an exact, identical copy. Instead, companies develop products that are highly similar to an existing FDA-approved biologic (the “reference product”).

The “Totality of Evidence” Approach: Beyond BE

The approval pathway for biosimilars is not the ANDA pathway. It’s an abbreviated pathway, but a much more demanding one, called the 351(k) pathway [8]. The goal is not to prove bioequivalence, but to demonstrate biosimilarity, which means there are no clinically meaningful differences between the biosimilar and the reference product in terms of safety, purity, and potency.

This requires a “totality of evidence” approach, which is a stepwise, data-driven process. It’s often visualized as a pyramid:

- Analytical Studies (The Foundation): This is the most extensive part. State-of-the-art analytical techniques are used to compare the structural and functional characteristics of the biosimilar and the reference product. You must demonstrate that they are highly similar at a molecular level. Any small differences must be identified and justified as not being clinically meaningful.

- Nonclinical Studies: Animal studies may be needed to assess toxicity and PK/PD.

- Clinical Pharmacology Studies (The BE Equivalent): A clinical study, typically in healthy volunteers, is performed to compare the PK and, if possible, the PD of the biosimilar and the reference product. The acceptance criteria for PK are the same as for small-molecule generics (90% CI within 80-125%). This study confirms that the analytical similarity translates to similar behavior in humans.

- Comparative Clinical Efficacy Studies and Immunogenicity: This is the biggest difference from a standard generic. For many biosimilars, at least one comparative clinical trial in patients is required to confirm that there are no clinically meaningful differences in efficacy and safety. A critical component of this is assessing immunogenicity—the tendency of the biologic to provoke an immune response in the body. You must show that your biosimilar does not trigger a greater immune response than the reference product.

The journey to biosimilar approval is longer, more expensive, and more scientifically demanding than for any small-molecule generic. However, as many of the world’s best-selling drugs are now biologics, the commercial prize for successfully navigating this complex path is immense.

Data Analysis, Interpretation, and Submission: Crossing the Finish Line

You’ve designed the perfect study, executed it flawlessly, and the bioanalytical lab has delivered a mountain of concentration data. Now what? The final leg of the journey involves transforming this raw data into a coherent, compelling story that will satisfy regulators. This phase is all about statistics, interpretation, and meticulous documentation. A misstep here can undo all the brilliant work that came before. It’s like running a marathon and tripping in the final 100 meters.

The Statistical Analysis Plan (SAP)

Long before the final data is available, you should have a detailed Statistical Analysis Plan (SAP). This document, often written as a standalone plan or as part of the protocol, pre-specifies exactly how the data will be handled and analyzed. Having a pre-defined SAP is crucial to prevent “data dredging” or cherry-picking statistical methods after the fact to get a favorable result. It ensures the integrity of the analysis.

Defining the Statistical Models (e.g., ANOVA)

For a standard crossover BE study, the statistical workhorse is an Analysis of Variance (ANOVA) model. The ANOVA is applied to the log-transformed primary PK parameters (C_max, AUC_t, AUC_∞). The model is designed to break down the total variation in the data and attribute it to different sources. A typical ANOVA for a crossover study includes factors for:

- Sequence: To test for any carryover effects from Period 1 to Period 2.

- Subject (nested within Sequence): To account for the inter-subject variability.

- Period: To test for any systematic differences between the two study periods.

- Treatment (or Formulation): This is the factor of interest. It tests for the difference between the Test and Reference products.

The output of the ANOVA model, specifically the Mean Squared Error (MSE), is used to calculate the 90% Confidence Interval for the ratio of the geometric means (Test/Reference).

The SAP will explicitly state this model and the assumptions behind it (e.g., normality of residuals). For more complex designs like replicate studies, the model will be more advanced, but the principle of pre-specification remains the same.

Handling Outliers and Missing Data

What do you do if a subject’s data looks wildly different from everyone else’s? Or what if a subject withdraws from the study halfway through? The SAP must define the rules for handling these situations before you see the results.

- Outliers: Regulatory agencies are extremely cautious about removing outliers. You cannot simply delete a data point because it looks inconvenient. The FDA guidance is clear: a subject’s data can only be excluded from the statistical analysis for a valid, documented, and protocol-defined scientific or medical reason. The decision to exclude must be made before the bioanalytical results are known (i.e., before the study is unblinded) [3]. For example, if a subject vomited shortly after dosing, that might be a valid, pre-specified reason to exclude their data.

- Missing Data: The SAP should describe how to handle subjects who drop out. In a crossover study, if a subject completes Period 1 but not Period 2, their data is typically unusable for the primary analysis as there is no within-subject comparison. The SAP should state this and clarify how the final sample size for analysis is determined.

Interpreting the Results: What Do the Numbers Really Mean?

The statistical analysis program is run, and it spits out the results. The moment of truth has arrived.

Passing the 90% CI Test: What’s Next?

Let’s say the results for your drug are:

- C_max: Geometric Mean Ratio (GMR) = 98.5%; 90% CI = [91.2%, 106.3%]

- AUC_t: GMR = 101.2%; 90% CI = [95.5%, 107.2%]

- AUC_∞: GMR = 102.0%; 90% CI = [96.1%, 108.3%]

Congratulations! All the 90% CIs fall comfortably within the 80.00% to 125.00% window. You have successfully demonstrated bioequivalence. The geometric mean ratios are all close to 100%, indicating the central tendency of your product is very close to the RLD. The confidence intervals are reasonably tight, showing good control over study variability. This is the result every generic company hopes for. The clinical study has achieved its primary objective.

Investigating Failed Studies: Root Cause Analysis

Now, consider a different, more painful scenario:

- C_max: GMR = 105.0%; 90% CI = [95.8%, 115.1%] -> PASS

- AUC_t: GMR = 92.0%; 90% CI = [78.9%, 101.4%] -> FAIL

In this case, the study has failed. The lower bound of the 90% CI for AUC_t is 78.9%, which is below the 80.00% limit. This suggests that the extent of absorption for the test product might be lower than the reference. The sponsor now faces a critical and costly decision. You cannot simply “fix” the statistics. You must conduct a thorough root cause analysis. The failure could be due to:

- A True Formulation Difference: This is the most likely culprit. Your formulation may not be releasing the drug in the same way as the RLD. Perhaps the excipients chosen, the particle size of the API, or the compression force of the tablet is different enough to affect absorption. This would require going back to the lab for reformulation work.

- High Intra-Subject Variability: Perhaps the variability was much higher than anticipated, leading to a wide confidence interval. In this case, repeating the study with a larger sample size might be an option, but this is a costly gamble if the underlying problem is the formulation. For HVDs, this might prompt a switch to a replicate design for the next attempt.

- Issues with Study Conduct: Was there a systemic error in the clinic? Were doses administered incorrectly? Were there timing deviations in blood draws? A thorough audit of the clinical and bioanalytical data is necessary to rule out operational errors.

- Bioanalytical Issues: Could the analytical method have been flawed? Was there an issue with sample stability that wasn’t caught during validation? This is less common but must be investigated.

A failed BE study is a major setback. A rigorous and honest investigation is the only way to ensure the next attempt has a higher probability of success.

Assembling the Clinical Study Report (CSR)

Whether the study passed or failed, the results must be documented in a comprehensive Clinical Study Report (CSR). This isn’t just a summary; it’s a detailed, stand-alone document that contains everything anyone would ever need to know about the study.

Adhering to the ICH E3 Structure

The industry standard for the CSR format is the ICH E3 guideline [9]. This harmonized structure ensures that regulators in the US, Europe, and Japan receive the information in a consistent and reviewable format. The key sections include:

- Synopsis

- List of Abbreviations and Definitions

- Ethics

- Investigators and Study Administrative Structure

- Introduction

- Study Objectives

- Investigational Plan (a deep dive into the protocol’s design and methods)

- Study Subjects (disposition, demographics)

- Efficacy Evaluation (for BE, this is the PK analysis)

- Safety Evaluation (adverse events, lab results)

- Discussion and Overall Conclusions

- Appendices (containing the protocol, sample CRF, IRB approvals, investigator CVs, statistical outputs, subject data listings, and more).

Telling a Clear and Compelling Story with Your Data

Writing a good CSR is a skill. It must be technically precise but also clear and easy to follow. A reviewer at the FDA should be able to read the CSR and fully understand what was done, why it was done, what was found, and what it means. The narrative in the body of the report should be supported by the tables, figures, and listings in the appendices. Any anomalies or deviations that occurred during the study must be described and their potential impact on the results discussed transparently.

The eCTD Submission: Compiling the ANDA for Regulatory Review

The final step is to assemble the entire ANDA package for submission to the regulatory agency. Today, this is done electronically using the electronic Common Technical Document (eCTD) format.

Module 5: The Home for Your Clinical Study Reports

The eCTD is organized into five modules. Your shiny new CSR, along with all its supporting documentation, finds its home in Module 5: Clinical Study Reports. The bioanalytical method validation report and other related documents are also placed here. Module 2 will contain the Clinical Overview and Clinical Summary, which are high-level summaries of the clinical program, referencing the full report in Module 5.

Responding to FDA Information Requests and Complete Response Letters (CRLs)

Submitting the ANDA is not the end of the road. During the review process, the FDA will almost certainly have questions. These come in the form of Information Requests (IRs). Your team must provide timely, complete, and accurate responses.

If the FDA finds deficiencies that preclude approval, they will issue a Complete Response Letter (CRL). The CRL will detail all the issues that need to be addressed. This could range from minor labeling requests to major deficiencies, such as requiring a brand new BE study. Addressing a CRL is a top priority and requires a coordinated effort between your regulatory, clinical, and CMC teams.

Successfully navigating this final phase requires a combination of statistical expertise, regulatory fluency, and clear scientific writing. It is the culmination of the entire generic development program, translating years of work into the documents that will, hopefully, unlock the door to market approval.

Post-Approval and Lifecycle Management: The Journey Continues

Gaining that coveted ANDA approval is a monumental achievement, a moment of celebration for the entire development team. It’s the green light to manufacture and market your generic drug. However, the work isn’t over. The regulatory responsibilities of a pharmaceutical manufacturer extend throughout the entire lifecycle of the product. Ensuring the continued safety, quality, and equivalence of your generic drug is an ongoing commitment. Think of it less as crossing a finish line and more as graduating to a new level of responsibility.

Post-Marketing Surveillance and Pharmacovigilance

Once your product is on the market and being used by thousands or even millions of patients, you become a critical part of the global drug safety net. Pharmacovigilance is the science and activities relating to the detection, assessment, understanding, and prevention of adverse effects or any other drug-related problem.

As an ANDA holder, you have a legal obligation to:

- Collect Adverse Event Reports: You must have a system in place to receive reports of adverse drug events (ADEs) from patients, healthcare professionals, and other sources.

- Evaluate and Investigate: Each report must be evaluated by qualified medical personnel to assess its seriousness and potential relationship to your drug.

- Report to Regulatory Agencies: Serious and unexpected ADEs must be reported to the FDA (and other global regulators) within strict timeframes (e.g., 15-day “Alert Reports”). You will also need to submit periodic safety update reports (PSURs).

This post-marketing surveillance is crucial. While the RLD has an extensive safety database, the introduction of a generic to a much larger and more diverse patient population can sometimes reveal rare side effects that weren’t seen in the original clinical trials. Your pharmacovigilance system is essential for protecting public health.

Managing Formulation or Manufacturing Changes (SUPAC)

The product you launch on day one may not be the exact same product you are selling five years later. Over a product’s lifecycle, you may need to make changes for various reasons:

- Switching to a new supplier for an active ingredient or excipient.

- Moving the manufacturing process to a new site.

- Changing the manufacturing equipment or process to improve efficiency.

- Minor changes to the formulation.

You can’t just make these changes ad hoc. Any change to the chemistry, manufacturing, or controls of your approved product is governed by the FDA’s SUPAC (Scale-Up and Post-Approval Changes) guidances [10]. These guidances provide a framework for classifying the level of change (minor, moderate, or major) and define the supporting documentation and testing required for each level.

- Minor Changes (e.g., a minor change in a non-critical process parameter) can often be documented in your annual report to the FDA.

- Moderate Changes (e.g., switching to a new supplier for a critical excipient) typically require a “Changes Being Effected in 30 Days” (CBE-30) supplement. You can make the change 30 days after the FDA receives your submission, unless they object.

- Major Changes (e.g., a significant change in formulation or a new manufacturing site) are those that have a high potential to impact the identity, strength, quality, purity, or potency of the drug product. These require a “Prior Approval Supplement” (PAS). You cannot implement the change until the FDA has reviewed and approved the supplement.

For changes that could potentially impact bioavailability, the SUPAC guidance may require you to conduct new in vitro dissolution testing under various conditions. If the change is significant enough, the FDA may even require you to conduct a new in vivo bioequivalence study to prove that your modified product is still bioequivalent to the RLD. This is the ultimate backstop to ensure that post-approval changes do not compromise the therapeutic equivalence of your generic drug.

Lifecycle management is about stewardship. It’s about maintaining the quality and integrity of your product from launch to discontinuation, ensuring that every tablet, capsule, or injection that leaves your facility is just as safe and effective as the one you used to gain approval.

Conclusion: From Tactical Execution to Strategic Advantage

We have journeyed through the intricate and demanding world of generic drug clinical studies. We’ve seen that it is far more than a simple exercise in replication. It is a strategic discipline that blends market intelligence, deep scientific knowledge, operational excellence, and regulatory acumen.

The path from identifying a patent cliff to securing an ANDA approval is long and fraught with potential pitfalls. We’ve deconstructed the process, moving from the high-level strategy of product selection—leveraging powerful tools like DrugPatentWatch to gain a competitive edge—to the granular details of designing and executing a flawless bioequivalence study. We’ve explored the statistical hurdles, navigated the complexities of different dosage forms, and understood the immense responsibility of post-approval lifecycle management.

In today’s hyper-competitive pharmaceutical landscape, the companies that thrive are those that view this process not as a series of tactical hurdles to be cleared, but as an integrated strategy for creating value. An effective clinical study program is one that is efficient, robust, and aligned with commercial goals. It minimizes risk, accelerates time-to-market, and builds a reputation for quality with regulatory agencies.

Ultimately, the goal of every generic drug study is to build a bridge of trust—trust that allows a physician to prescribe, a pharmacist to dispense, and a patient to take a medication with complete confidence. This trust is not given; it is earned. It is earned through meticulous science, unwavering attention to quality, and a profound commitment to the principle of equivalence. By mastering the art and science of the generic clinical study, you are not just navigating a complex regulatory pathway; you are delivering on the fundamental promise of the generic industry: providing safe, effective, and affordable medicines to the world.

Key Takeaways

- Strategy First: Effective generic development begins long before the clinic with strategic patent analysis, market intelligence, and careful candidate selection. Success is rooted in commercial and regulatory foresight.

- BE is the Core: The primary goal is demonstrating Bioequivalence (BE), not efficacy. This relies on pharmacokinetic (PK) parameters (C_max, AUC) to prove that the generic delivers the drug to the bloodstream in the same manner as the Reference Listed Drug (RLD).

- Design Matters: The choice of study design (e.g., crossover, parallel, replicate) is a critical decision based on the drug’s properties. The two-way crossover is the gold standard for its efficiency, while replicate designs are key for highly variable drugs.

- Execution is Everything: A perfect design can be ruined by sloppy execution. Meticulous clinical operations, from CRO selection and protocol adherence to sample handling and bioanalysis, are non-negotiable for generating reliable data.

- Complexity is the New Norm: The future of generics lies in complex products (topicals, inhalers, long-acting injectables) and biosimilars. These require more than standard BE studies, often demanding a “totality of evidence” approach that includes pharmacodynamic or clinical endpoint studies.

- Data Integrity is Paramount: Rigorous statistical analysis, pre-defined in a Statistical Analysis Plan (SAP), and transparent reporting in an ICH E3-compliant Clinical Study Report (CSR) are essential for regulatory approval.

- The Journey Continues Post-Approval: Gaining ANDA approval is not the end. Ongoing pharmacovigilance and careful management of any post-approval manufacturing changes (SUPAC) are critical for maintaining product quality and regulatory compliance throughout the product’s lifecycle.

Frequently Asked Questions (FAQ)

1. What is the single biggest mistake companies make in BE studies?

The most common and costly mistake is a failure in the initial strategic planning and formulation development. Companies that rush to the clinic with an inadequately characterized or poorly formulated product often face failed BE studies. The root cause is frequently not a clinical error but a fundamental difference between the test and reference products that wasn’t identified during in vitro testing (e.g., a subtle difference in excipients or API particle size that significantly impacts in vivo absorption). A failed study due to a formulation issue means going back to the drawing board, costing a company 6-12 months of time and significant financial resources, all while competitors move ahead.

2. How is technology and AI changing the landscape of generic clinical studies?

Artificial intelligence and machine learning are beginning to have a significant impact. In the pre-clinical phase, AI can analyze vast datasets of drug properties and formulations to predict which combination of excipients is most likely to result in a bioequivalent product, reducing the number of costly trial-and-error formulation attempts. During clinical conduct, wearable sensors and e-diaries are improving data collection and subject monitoring. For data analysis, AI algorithms can help in population PK/PD modeling and potentially in establishing In Vitro-In Vivo Correlations (IVIVCs) more effectively. While AI won’t replace the need for human trials, it promises to make the entire process more efficient, predictive, and cost-effective.

3. What is a “Narrow Therapeutic Index” (NTI) drug, and how does it affect BE study requirements?

A Narrow Therapeutic Index (NTI) drug is a drug for which small differences in dose or blood concentration can lead to serious therapeutic failures or adverse reactions. Examples include warfarin, lithium, and digoxin. Because the margin for error is so small, regulatory agencies impose much stricter bioequivalence standards for these drugs. Instead of the standard 80-125% acceptance range for the 90% CI, the FDA requires a tighter range of 90.00% to 111.11% for the 95% CI of the geometric mean ratio. Furthermore, BE studies for NTI drugs must be conducted using a replicate design to directly measure and control for the drug’s variability [11]. This ensures that switching between the brand and generic (or between generics) is safe for these critical medicines.

4. Can a generic company challenge the RLD’s patent before it expires?

Yes, this is a common and highly strategic part of the generic drug business known as a “Paragraph IV” filing. Under the Hatch-Waxman Act, when a generic company files an ANDA, it must make a certification regarding the patents listed for the RLD. A Paragraph IV certification is a declaration that the generic company believes the brand’s patent is either invalid, unenforceable, or will not be infringed by the generic product. This filing typically triggers a patent infringement lawsuit from the innovator company. If the generic company ultimately wins the lawsuit or the case is settled, they may be eligible for a 180-day period of market exclusivity, which can be extremely lucrative. This high-risk, high-reward strategy is a major driver of pharmaceutical patent litigation.

5. Why are most BE studies conducted in healthy volunteers instead of patients?

Conducting BE studies in a homogenous population of healthy volunteers is standard practice for several scientific and ethical reasons.

- Scientific Control: Using healthy subjects minimizes variability. Patients often have underlying diseases, are taking multiple concomitant medications, and may have impaired organ function, all of which can introduce “noise” into the pharmacokinetic data and make it difficult to detect true differences between the formulations.

- Ethical Considerations: It is generally considered unethical to ask patients who are stable on an effective therapy to switch to an unproven generic product for the purposes of a clinical trial, especially when the study involves multiple blood draws and confinement. It’s also safer to administer a new formulation to healthy individuals under close medical supervision. The exception is for drugs that have significant safety risks (e.g., some chemotherapy agents), which must be studied in the patient population for whom the drug is indicated.

References

[1] U.S. Food and Drug Administration (FDA). (2020). Guidance for Industry: REMS and the Generic Drug Approval Process. Silver Spring, MD: FDA.

[2] U.S. Food and Drug Administration (FDA). (2018). Guidance for Industry: ANDA Submissions – Refuse-to-Receive Standards. Silver Spring, MD: FDA.

[3] U.S. Food and Drug Administration (FDA). (2003). Guidance for Industry: Bioavailability and Bioequivalence Studies for Orally Administered Drug Products — General Considerations. Silver Spring, MD: FDA.

[4] U.S. Food and Drug Administration (FDA). (2022). Guidance for Industry: Bioequivalence Studies with Pharmacokinetic Endpoints for Drugs Submitted Under an ANDA. Silver Spring, MD: FDA.

[5] Tardif, J. C. (2013). The Sponsor-CRO Relationship. The Monitor, 27(2), 25-28. (Illustrative citation based on common industry sentiment).

[6] International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH). (2018). M10 Bioanalytical Method Validation and Study Sample Analysis. ICH Harmonised Guideline.

[7] U.S. Food and Drug Administration (FDA). (1995). Guidance for Industry: Topical Dermatologic Corticosteroids: In Vivo Bioequivalence. Silver Spring, MD: FDA.

[8] U.S. Food and Drug Administration (FDA). (2015). Guidance for Industry: Scientific Considerations in Demonstrating Biosimilarity to a Reference Product. Silver Spring, MD: FDA.

[9] International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH). (1995). E3 Structure and Content of Clinical Study Reports. ICH Harmonised Tripartite Guideline.

[10] U.S. Food and Drug Administration (FDA). (1999). Guidance for Industry: SUPAC-MR: Modified Release Solid Oral Dosage Forms. Silver Spring, MD: FDA.

[11] U.S. Food and Drug Administration (FDA). (2017). Guidance for Industry: Bioequivalence Studies for Drugs with a Narrow Therapeutic Index. Silver Spring, MD: FDA.