The pharmaceutical industry stands at a fascinating juncture, where the pursuit of affordable healthcare intersects with the pinnacle of scientific innovation. Generic drugs, often perceived as mere copies of their brand-name counterparts, are, in reality, products of sophisticated scientific endeavor and strategic foresight. They represent a critical pillar of global healthcare, driving down costs and expanding patient access to essential medicines. Yet, the journey from patent expiry to market entry is fraught with complex formulation challenges that demand ingenuity, advanced technology, and a meticulous understanding of both drug science and regulatory frameworks.

This report delves into the intricate world of generic drug formulation, dissecting the core challenges, exploring pioneering solutions, and illuminating the strategic advantages available to companies that master this demanding domain. We will navigate the physicochemical complexities of matching reference products, the nuances of specialized dosage forms, and the critical role of intellectual property and competitive intelligence in shaping market success.

The Strategic Imperative of Generic Drug Development

Generic drugs are not just cheaper alternatives; they are fundamental to the economic viability and accessibility of healthcare systems worldwide. Their development and market entry are driven by a compelling blend of public health necessity and astute business strategy.

Generic Drugs: Pillars of Affordable Healthcare

The very foundation of generic drug development rests on the principle of therapeutic equivalence, a concept that underpins patient trust and market acceptance.

Defining Generic Drugs and Bioequivalence: The Cornerstone of Trust

At its heart, a generic drug is a pharmaceutical product containing the same active chemical substance as a proprietary drug that was once protected by patents. These drugs are permitted for sale once the original patents expire . While the active pharmaceutical ingredient (API) must be identical to the original, generic drugs are allowed to differ in various characteristics such as the manufacturing process, formulation, excipients (inactive ingredients), color, taste, and packaging . This flexibility, however, introduces a profound scientific challenge.

The U.S. Food and Drug Administration (FDA) mandates that generics be identical to, or fall within an acceptable bioequivalent range of, their brand-name counterparts, specifically concerning pharmacokinetic (PK) and pharmacodynamic (PD) properties . What does “bioequivalent” truly mean in practice? It signifies that the generic version must release its active ingredient into the bloodstream at virtually the same speed and in virtually the same amounts as the original drug . This is typically demonstrated through rigorous in vivo studies in human subjects, where key PK parameters like peak drug plasma concentration (Cmax) and the area under the drug plasma concentration versus time profile (AUC) are characterized and compared. For a generic to be deemed bioequivalent, the 90% confidence interval of the geometric mean test/reference ratios for both AUC and Cmax must fall within the limits of 80–125% .

Consider the subtle, yet significant, distinction here: while the public often assumes generic drugs are exact chemical clones, the regulatory definition of “bioequivalence” allows for variations. For instance, a different salt or ester of the active ingredient might be used, or different inactive ingredients might be incorporated . This creates a unique challenge for generic developers, often referred to as the “invisible” equivalence challenge. They are not merely copying a formula; they are reverse-engineering a performance profile. This demands an intricate understanding of how changes in formulation components, even seemingly inert ones, can influence the drug’s absorption, distribution, metabolism, and excretion (ADME) within the human body. It’s a delicate dance of achieving identical therapeutic outcomes through potentially different compositional pathways.

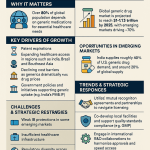

The Economic and Societal Impact of Generic Entry

The widespread adoption of generic drugs has fundamentally reshaped global healthcare economics, delivering monumental cost savings and enhancing patient access.

The economic impact is staggering. A single generic competitor entering the market can lead to price reductions of 30%, while the presence of five competing generics can drive prices down by nearly 85% . This competitive dynamic has translated into immense savings for healthcare systems and patients alike. From 2009 to 2019, generic drugs saved the U.S. healthcare system an estimated $2.2 trillion . More recently, in 2022 alone, new generic approvals generated approximately $53.3 billion in savings .

The global generic drugs market is a testament to this economic power. Valued at USD 445.62 billion in 2024, it is projected to grow to approximately USD 728.64 billion by 2034, demonstrating a Compound Annual Growth Rate (CAGR) of 5.04% . This robust growth is primarily fueled by the inherently lower cost of generics compared to branded drugs and the continuous expiration of patents on blockbuster medications .

Beyond the raw numbers, the societal benefits are profound. Generics significantly improve patient access to essential medications, particularly benefiting low-income populations and developing countries where affordability is a critical barrier . Moreover, the introduction of multiple generic manufacturers for a single drug product helps stabilize the supply chain and mitigates the risk of drug shortages, a growing concern in today’s complex global environment .

However, this picture of success is not without its complexities. The very mechanism that drives down drug prices—intense competition—can paradoxically strain the generic manufacturing sector. The pursuit of aggressive price reductions often leads to razor-thin profit margins in conventional generic segments . This can create supply chain vulnerabilities and even compromise quality if manufacturers are forced to cut corners to remain competitive . This delicate balance between maximizing cost savings for consumers and ensuring the sustainable profitability and quality of generic manufacturers is a critical challenge that demands continuous strategic innovation within the industry.

To underscore the profound economic influence of generic entry, consider the typical price trajectory following patent expiration:

| Number of Generic Competitors | Approximate Price Reduction vs. Brand |

| 1 | 30% |

| 3 | 20% |

| 5 | 85% |

| 10+ | 70-80% |

This table vividly illustrates how competition acts as a powerful economic force, driving down prices and delivering substantial value to healthcare systems and patients.

Beyond Replication: The Evolving Landscape of Generic Formulation

The journey of a generic drug is far more intricate than simply copying a formula; it’s an evolving scientific and business challenge that demands innovation.

Why Generic Formulation is a Distinct Scientific and Business Challenge

Unlike the development of an innovator drug, which necessitates extensive and costly clinical trials to prove safety and efficacy from scratch, generic drug development operates on an abbreviated pathway. The U.S. FDA’s Abbreviated New Drug Application (ANDA) process and the European Medicines Agency’s (EMA) Marketing Authorisation Application (MAA) for generics allow manufacturers to bypass these lengthy clinical trials because the safety and efficacy of the active ingredient have already been established by the Reference Listed Drug (RLD) .

Instead, the core challenge for generic developers lies in demonstrating therapeutic equivalence through rigorous bioequivalence (BE) studies . This means proving that the generic product delivers the same active substance, at the same rate and extent, as the innovator drug . But here’s the rub: achieving this “sameness” is anything but simple. Generic formulations are permitted to differ from the RLD in their inactive ingredients, manufacturing processes, and even the specific salt or ester forms of the API . These seemingly minor differences can, in fact, profoundly impact a drug’s performance, stability, and bioavailability in the human body .

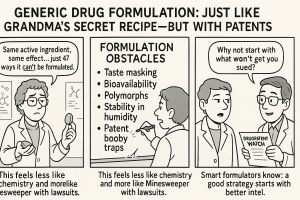

This leads to a unique predicament for generic developers: they must replicate the performance of an RLD without having full access to its proprietary formulation details or manufacturing blueprints. This is often described as the challenge of “known unknowns” in RLD formulation. It necessitates extensive reverse-engineering, a process often termed “de-formulation,” to meticulously understand the RLD’s critical quality attributes (CQAs) and precisely how they are achieved . It’s akin to a master chef trying to replicate a secret recipe by tasting the dish and analyzing its texture, rather than having the ingredient list and cooking instructions. This transforms generic development from a simple copying exercise into a sophisticated scientific and engineering challenge, demanding deep analytical capabilities and innovative formulation expertise.

The Shift Towards Complex Generics: A New Frontier

The generic pharmaceutical market is not static; it is constantly evolving, driven by both scientific advancement and economic pressures. A significant trend observed in recent years is the industry’s strategic pivot towards “complex generics.”

Why this shift? The market for simpler generic drugs has become increasingly saturated, leading to intense competition and, as discussed, razor-thin profit margins . To sustain growth and profitability, pharmaceutical companies are increasingly focusing on these more challenging, yet potentially more lucrative, complex generic products . These products are inherently more difficult to develop, often resulting in fewer generic competitors and thus greater market potential .

Complex generics are a diverse category, encompassing products with:

- Complex Active Pharmaceutical Ingredients (APIs): This includes intricate molecules like peptides, complex mixtures, or those derived from natural sources .

- Complex Formulations: Examples include liposomes, nanoemulsions, protein-drug complexes, and iron colloids, which require comprehensive physicochemical characterization to ensure equivalence .

- Complex Dosage Forms or Routes of Delivery: This covers a wide range, from modified-release (MR) formulations designed for sustained or delayed drug release, to transdermal patches, and even locally acting drugs where systemic absorption is not the primary goal .

- Drug-Device Combinations: Products like metered-dose inhalers (pMDIs), dry powder inhalers (DPIs), and auto-injectors, where the drug formulation and the delivery device are inextricably linked and both must be equivalent to the RLD .

The development of these complex generics requires specific studies that go far beyond those needed for simple generics to demonstrate therapeutic equivalence . This often translates into substantial investment and a significant commitment of resources from manufacturers . For generic companies, this move into complex generics is not merely a scientific progression; it represents a fundamental strategic imperative. It’s a calculated move to escape the commoditization and intense price competition of simpler segments. This shift necessitates significant R&D investment, the adoption of novel formulation approaches, and a willingness to push the boundaries of pharmaceutical science. In essence, it is transforming generic companies from pure cost-cutters into innovators in their own right, capable of developing differentiated products that offer enhanced therapeutic profiles and address unmet patient needs.

Unpacking the Core Formulation Challenges

The journey to replicate a brand-name drug’s performance is paved with scientific and technical hurdles. Let us dissect the core formulation challenges that generic developers must meticulously overcome.

The Physicochemical Conundrum: Matching the Reference Listed Drug (RLD)

At the heart of generic drug development lies the intricate task of matching the physicochemical properties of the RLD, a challenge that extends beyond simple chemical identity.

Q1/Q2/Q3 Sameness: The Quest for Equivalence

The regulatory framework for generic drugs often hinges on the concept of “sameness,” particularly concerning inactive ingredients. This is encapsulated in the terms “Q1/Q2 sameness” and “Q3 sameness.”

Q1 (Qualitative) sameness dictates that a proposed generic formulation must contain the same inactive ingredients as its RLD. To demonstrate this, applicants are required to provide detailed information on the chemistry of each inactive ingredient, along with characterization data if necessary . This isn’t just a checklist; it demands a thorough understanding of the excipient’s identity and purity.

Q2 (Quantitative) sameness takes this a step further, requiring that the concentrations of these inactive ingredients in the generic product be the same as those used in the RLD. The FDA generally interprets “Q2 sameness” to mean that the concentration must be within 95-105% of the RLD concentration .

Beyond the chemical composition of inactive ingredients, Q3 sameness extends the equivalence requirement to the physical and structural characteristics of the drug product. This means the generic must exhibit similar physical and structural properties to the reference product, encompassing aspects like particle morphology, surface potential, and size distribution .

For certain dosage forms, such as parenteral (injectable), ophthalmic (eye), and otic (ear) products, Q1/Q2 sameness is often a regulatory requirement . However, even here, minor differences in components like preservatives, buffers, or antioxidants may be allowed, provided the applicant can demonstrate that these differences do not affect the safety or efficacy of the proposed drug product . For other routes of administration where Q1/Q2 sameness is not strictly mandated, a non-Q1/Q2 application may be submitted, although product-specific guidances (PSGs) might then recommend different bioequivalence (BE) approaches .

This intricate web of Q1/Q2/Q3 requirements illustrates a critical tension in generic drug development: regulators demand “sameness” to ensure safety and efficacy, yet they also allow for “permissible differences” to foster generic competition. Navigating this regulatory tightrope requires not only deep scientific understanding but also strategic regulatory engagement. Deviations, even seemingly minor ones, can trigger extensive additional studies, leading to significant delays or even outright rejection of an Abbreviated New Drug Application (ANDA) . The challenge lies in proving that any deviation in inactive ingredients or manufacturing processes does not compromise the drug’s performance, a task that often demands sophisticated analytical and bioequivalence testing.

Solubility and Dissolution: The Gateway to Bioavailability

For a drug to exert its therapeutic effect, it must first be absorbed into the bloodstream. For many oral medications, this journey begins with dissolution, and herein lies a significant hurdle for generic developers.

Low aqueous solubility is a pervasive problem in pharmaceutical formulation, affecting both novel chemical entities (NCEs) and generic drugs. It is estimated that more than 40% of NCEs developed in the pharmaceutical industry are practically insoluble in water . Why is this a problem? Because for any drug to be absorbed effectively, it must first be present in a dissolved form at the site of absorption . Factors contributing to poor solubility often include a molecule’s high melting point (MP) and high partition coefficient (logP), which indicate a preference for organic phases over aqueous ones . Poor solubility directly limits the extent to which a drug can be absorbed, thereby impacting its bioavailability.

Dissolution testing emerges as a fundamental analytical technique in this context. It serves as a crucial predictor of drug release and bioavailability, ensuring consistency in drug release and meeting stringent regulatory expectations for both innovator and generic products . For poorly water-soluble drugs, achieving “sink conditions”—where the drug dissolves readily into the dissolution medium—can be particularly challenging. In such cases, the incorporation of suitable surfactants into the dissolution medium is often necessary to facilitate the process .

To overcome these solubility and dissolution challenges, generic developers employ a range of enhancement techniques:

- Particle Size Reduction: Techniques like micronization and nano-milling are commonly used in the preformulation stage to increase the dissolution rate of APIs whose absorption is limited by their particle size (classified as BCS Class IIb drugs) . By increasing the surface area, the drug can dissolve more rapidly.

- Amorphous Solid Dispersion (ASD) and Lipid-Based Formulations: For compounds whose absorption is limited by their intrinsic solubility (BCS Class IIa), ASD technologies and lipid-based formulations have become primary approaches. ASD involves dispersing drug molecules within a water-soluble polymer matrix, significantly improving dissolution rates and bioavailability .

- Other Conventional Approaches: These include pH adjustment, salt formation to improve solubility, complexation (e.g., with cyclodextrins), and the strategic use of surfactants .

The Biopharmaceutics Classification System (BCS) is not merely an academic classification; it serves as a strategic compass for generic drug development. By categorizing drugs based on their solubility and permeability, the BCS framework directly guides the appropriate dissolution strategies and, crucially, determines whether a biowaiver for in vivo bioequivalence studies is feasible . For instance, BCS Class 1 drugs (high solubility, high permeability) and certain BCS Class 3 drugs (high solubility, low permeability) may be eligible for biowaivers, which can significantly reduce the need for costly and time-consuming in vivo studies, thereby streamlining development timelines and reducing overall costs . Understanding and leveraging a drug’s BCS classification is therefore a pivotal strategic decision in generic formulation, directly impacting the economic and temporal feasibility of a project.

Polymorphism: Controlling the Crystalline Identity

The solid-state properties of an active pharmaceutical ingredient (API) can hold the key to a drug’s performance, and few aspects are as critical, or as challenging, as polymorphism.

Polymorphism refers to the ability of a solid compound to exist in two or more distinct crystalline forms, each having the same chemical composition but differing in their molecular arrangement within the crystal lattice . This phenomenon is remarkably common in active pharmaceutical ingredients, with over 50% of all APIs existing in at least two polymorphic forms .

Why does this matter? Different polymorphic forms can dramatically alter a drug’s physicochemical properties. These variations can impact critical attributes such as solubility, dissolution rate, melting point, density, flowability, hygroscopicity (tendency to absorb moisture), and compaction characteristics . Consequently, these changes can profoundly affect the drug’s bioavailability and overall stability. A stark illustration of this impact is the case of Norvir® (ritonavir), an antiretroviral drug. A transformation of its API into a less soluble polymorphic form led to its market removal, highlighting the serious public health and commercial consequences of uncontrolled polymorphism .

Given these critical implications, stringent control and characterization of polymorphic forms are paramount. The U.S. FDA, for instance, requires a comprehensive polymorphism study as part of Abbreviated New Drug Application (ANDA) submissions to demonstrate equivalence to the reference listed drug . A suite of advanced analytical techniques is employed for identifying, characterizing, and quantifying these polymorphic forms:

- X-ray Powder Diffraction (XRPD): Provides unequivocal proof of polymorphism by analyzing the unique diffraction pattern of each crystal form .

- Thermal Analysis Techniques: Including Differential Scanning Calorimetry (DSC), Thermal Gravimetric Analysis (TGA), and Hot-Stage Microscopy (HSM), which reveal thermal transitions (melting, decomposition) and changes in mass associated with different polymorphs .

- Spectroscopic Methods: Raman spectroscopy and solid-state carbon-13 nuclear magnetic resonance (NMR-13C) provide insights into molecular structure and bonding within the crystal lattice .

Beyond initial characterization, continuous monitoring of polymorphic forms is essential throughout the drug development and manufacturing lifecycle to ensure consistent quality and prevent unintended transformations .

Polymorphism, therefore, is not merely a scientific curiosity; it is an intellectual property battleground and a constant quality control minefield. Innovator companies often patent-protect different crystalline forms of their APIs, creating complex “patent thickets” that generic developers must meticulously navigate . An unintentional change in polymorphic form during manufacturing, storage, or even due to mechanical stress (e.g., during tablet compression), can compromise a product’s performance, lead to batch failures, or, in severe cases, necessitate product recalls, posing significant public health concerns . This elevates polymorphism from a formulation hurdle to a multi-faceted strategic and operational risk that demands continuous vigilance and advanced analytical capabilities.

Stability and Degradation: Ensuring Shelf-Life and Integrity

A drug’s therapeutic utility is inextricably linked to its stability—its ability to maintain its intended properties over time. For generic drugs, demonstrating robust stability is a non-negotiable regulatory and quality requirement.

Drug stability refers to the capacity of a drug dosage form to retain its chemical, physical, and microbiological integrity, potency, and purity throughout its shelf-life when stored under specified environmental conditions, such as temperature, humidity, and light . This property is absolutely crucial for ensuring that the product remains safe and effective for patients from the moment of manufacture until its expiration date .

Pharmaceutical drugs are susceptible to various degradation pathways, which can compromise their integrity and lead to the formation of impurities. The major degradation pathways include:

- Hydrolysis: Chemical breakdown caused by water, often accelerated by extreme pH conditions (acid or base hydrolysis) . This can lead to the loss of structural components necessary for the molecule’s activity.

- Oxidative Degradation: Reactions involving oxygen, often catalyzed by light or metal ions, leading to changes in chemical bonds or the formation of new compounds .

- Photodegradation: Chemical changes induced by exposure to light, which can cause molecules to break down and become ineffective or even toxic .

- Thermal Degradation: Exposure to elevated temperatures can cause molecules to lose critical functional groups or undergo other structural changes .

To counteract these degradation processes and ensure long-term stability, robust formulation and stability-indicating testing strategies are indispensable . Key stabilization strategies include:

- Strategic Excipient Selection: Incorporating excipients with stabilizing properties, such as antioxidants (e.g., ascorbic acid, tocopherol) to prevent oxidative degradation, and pH modifiers or buffering agents to maintain the desired pH and prevent hydrolysis of acid- or base-sensitive drugs .

- Advanced Formulation Techniques: Methods like microencapsulation, which encloses drug particles within a protective shell, and lyophilization (freeze-drying), which removes water from the formulation, can provide physical protection and minimize exposure to environmental factors that trigger degradation .

- Optimized Packaging: The choice of container-closure system is critical. Packaging must effectively protect the drug product from light, air (oxygen), and moisture throughout its shelf life .

The stability of a drug product is not an isolated property; it is deeply intertwined with the entire manufacturing process, the quality of raw materials (especially excipients), and the chosen packaging. Problems arising during manufacturing scale-up, such as uncontrolled process variability or the presence of impurities originating from excipients, can directly compromise product stability . For example, certain excipients may contain trace impurities (e.g., reducing sugars, peroxides, aldehydes) that can react with the API and promote degradation pathways like Maillard reactions or oxidation . This means that a holistic approach, from meticulous raw material sourcing and rigorous in-process controls to appropriate final packaging, is essential to ensure long-term product integrity and prevent costly batch failures or regulatory issues.

To summarize these core physicochemical challenges and their mitigation, consider the following:

| Challenge | Description of Impact | Key Mitigation Strategies |

| Solubility | Poor absorption, low bioavailability, limited therapeutic effect. | Particle size reduction (micronization, nano-milling), Amorphous Solid Dispersion (ASD), lipid-based formulations, salt formation, pH adjustment, surfactants. |

| Dissolution | Inconsistent drug release, bioequivalence failure, sub-therapeutic levels. | Formulation optimization (excipient selection), biorelevant dissolution testing, use of surfactants in media, design of experiments (DoE). |

| Polymorphism | Changes in solubility, dissolution, stability, bioavailability; IP infringement risk. | Analytical control (XRPD, DSC, Raman), selection of stable polymorphic form, continuous monitoring throughout manufacturing. |

| Stability/Degradation | Loss of potency/purity, formation of toxic impurities, reduced shelf-life, safety concerns. | Antioxidants, pH modifiers/buffers, microencapsulation, lyophilization, appropriate container-closure systems, stability-indicating analytical methods. |

The Excipient Enigma: Selection, Compatibility, and Impact

Often overlooked, the “inactive” components of a drug formulation—excipients—play an unexpectedly active role in determining a generic drug’s success or failure.

Navigating Excipient Functionality and Regulatory Acceptance

Excipients are far from inert fillers; they are crucial functional components of a drug formulation. They perform a multitude of roles, from providing bulk to make a tablet large enough to handle, preventing it from crumbling, and helping it dissolve in the stomach or intestine, to imparting a pleasant taste and color . Given their diverse functions, the selection of appropriate excipients is of paramount importance in generic formulations, directly influencing the risk profile and overall performance of the drug .

However, the “inactive” label can be misleading. Excipients can, and often do, interact with the active pharmaceutical ingredient (API), leading to undesirable chemical reactions or degradation . For instance, the presence of adsorbed water during storage, changes in microenvironmental pH within the dosage form, or the activation of functional groups (or even impurities) present in excipients can promote various drug degradation pathways . Specific examples include:

- Maillard Reactions: Excipients containing reducing sugars (e.g., lactose, maltose, glucose) or even trace amounts of reducing sugars as impurities (e.g., in microcrystalline cellulose) can promote Maillard reactions with primary and secondary amine-containing drugs .

- Oxidation/Photodegradation: Peroxides or phenolic impurities found in excipients like povidone and crospovidone can lead to the oxidation or photodegradation of the drug .

- Aldehyde-induced Degradation: Aldehydes present in excipients such as lactose, microcrystalline cellulose (MCC), starch, and polyethylene glycol (PEG) can also cause drug degradation .

Regulatory bodies, including the FDA, are keenly aware of these potential interactions. They require detailed information on the chemistry and characterization of inactive ingredients to ensure Q1 (qualitative) and Q2 (quantitative) sameness, especially for critical dosage forms like parenteral, ophthalmic, and otic products .

The choice and quality of excipients, even when seemingly Q1/Q2 compliant, can subtly influence a generic drug’s in vivo performance, often acting as hidden variables in the complex equation of bioequivalence. This can lead to unexpected bioequivalence failures or even unforeseen adverse effects in patients . The fact that excipients from different vendors or even different grades from the same vendor may contain varying impurities further compounds this challenge . This means generic developers must go beyond merely meeting the Q1/Q2 checkboxes; they must conduct rigorous excipient compatibility studies, as excipient-related issues can be a root cause of significant formulation challenges and regulatory setbacks.

Mitigating Drug-Excipient Interactions and Impurity Risks

Given the potential for excipients to compromise drug stability and performance, drug-excipient compatibility studies (DECS) are a critical step during pre-formulation studies. These studies aim to identify and select appropriate excipients that will yield a stable and effective formulation . Indeed, DECS are not just good scientific practice; they are an obligatory part of regulatory submissions for Abbreviated New Drug Applications (ANDAs) .

Traditionally, DECS methods have been labor-intensive and lengthy. They typically involve preparing binary or multi-component physical mixtures of drugs and excipients, which are then placed on stability under accelerated conditions (often with or without added water) for extended periods, usually one to three months . While thorough, this approach can be a significant bottleneck in the accelerated generic development cycle. This has spurred the search for more efficient methods. Novel approaches, such as the “vial-in-vial” method, have been proposed to rapidly screen suitable excipients, with the potential to shorten the drug development cycle by many folds .

Ensuring excipient compatibility with active pharmaceutical ingredients (APIs) in complex formulations presents a particularly significant challenge . For example, polysorbates, commonly used excipients in many complex formulations (especially biologics), are known to be prone to degradation. This degradation can occur through various pathways, including oxidation (e.g., due to peroxides or exposure to light and oxygen) and enzymatic degradation (e.g., by lipases) . Such degradation can lead to the formation of subvisible and visible particles, directly impacting the drug product’s critical quality attributes (CQAs) and potentially raising patient safety concerns .

The complexity and time-consuming nature of traditional DECS highlight a growing imperative for predictive excipient science. There is a clear need for advanced analytical techniques and computational models to anticipate drug-excipient interactions and identify impurity risks much earlier in the development process. This proactive approach, rather than relying on lengthy empirical testing, can significantly reduce costly late-stage failures, accelerate time-to-market, and ultimately enhance the overall efficiency and success rate of generic drug development programs.

Manufacturing and Scale-Up: Bridging Lab to Commercial Reality

The journey of a generic drug from a laboratory bench to mass production is a formidable undertaking, riddled with challenges related to process consistency and supply chain resilience.

Process Variability: Maintaining Consistency at Scale

For a generic drug to be approved and marketed, manufacturers must demonstrate that their chosen manufacturing process can reliably and consistently produce a high-quality product that is bioequivalent to the Reference Listed Drug (RLD) . This requires submitting detailed information in the Abbreviated New Drug Application (ANDA) regarding the drug’s formulation, composition, the specific manufacturing process, and comprehensive quality control measures .

However, the transition from small-scale laboratory formulation to commercial-scale manufacturing is often fraught with difficulties. This phase is frequently referred to as the “valley of death” in drug development due to the high rate of failure. For generic drugs, this challenge is exacerbated by the need to precisely match the RLD’s in vivo performance, often while utilizing different equipment, processes, or even raw material suppliers than the innovator . Common problems encountered during scale-up include wasted commercial batches, failure to meet established specifications, and unacceptable process variability .

To bridge this gap and ensure consistency, it is crucial to establish a clear and robust relationship between formulation variables, manufacturing process parameters (including attributes of the drug substance and excipients), and the final product quality . This involves meticulously identifying the sources of variability at each step of the manufacturing process and implementing controls to mitigate them. Without this deep process understanding, achieving reproducible quality and bioequivalence at commercial scale remains a significant hurdle.

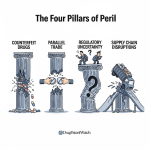

Supply Chain Vulnerabilities: Ensuring Raw Material Flow

The globalized nature of the pharmaceutical industry, while offering cost advantages, has also introduced significant vulnerabilities into the supply chain, directly impacting generic drug formulation and production.

Generic drug manufacturers frequently encounter substantial supply chain constraints, including shortages of critical ingredients and limitations in manufacturing capacity, both of which can severely impede the timely delivery of products to market . A major contributing factor to this fragility is the industry’s widespread reliance on offshore manufacturing for active pharmaceutical ingredients (APIs) and other essential components. Startlingly, over 80% of active pharmaceutical ingredients used in the U.S. are manufactured outside the country, with a significant portion originating from China and India .

This globalized supply chain, while initially driven by cost reduction (lower labor costs, less stringent regulatory standards in some regions), comes at a considerable price . It exposes generic manufacturers to a range of geopolitical risks, including trade policies like tariffs, and potential disruptions stemming from regional crises or quality control issues in foreign facilities .

The implication here is profound: geopolitical risks can directly translate into acute formulation challenges for generic manufacturers. If tariffs are imposed on critical imported ingredients, or if a regional crisis disrupts the supply of a specific excipient or API, generic companies face a difficult choice. They must either reformulate their product (a complex and time-consuming process that requires re-demonstrating bioequivalence and obtaining regulatory approval, if even permissible) or risk drug shortages. This directly impacts patient access and can severely erode a company’s profitability. This elevates supply chain management from a logistical concern to a strategic imperative that directly influences formulation decisions and overall business resilience.

Specialized Formulation Challenges Across Dosage Forms

While the fundamental principles of generic drug development apply universally, specific dosage forms present unique and often complex formulation challenges that demand specialized expertise and innovative solutions.

Modified-Release (MR) Formulations: Precision in Drug Delivery

Modified-release (MR) formulations represent a significant leap in drug delivery, offering enhanced patient convenience and improved therapeutic outcomes. However, developing generic versions of these complex systems is a formidable task.

Sustained, Delayed, and Pulsatile Release: Complexities of Control

MR products are sophisticated dosage forms meticulously engineered to control the rate, time, or location of drug release within the body. Their primary objective is to achieve desired efficacy and safety profiles, often by maintaining stable drug concentrations in the bloodstream over extended periods, thereby avoiding the undesirable “peaks and troughs” associated with immediate-release formulations . This controlled release can significantly improve patient compliance by reducing the frequency of dosing . Examples include prolonged-action, sustained-release, and delayed-release formulations, each designed to meet specific therapeutic needs . These systems frequently rely on specialized polymers and intricate designs to orchestrate the precise release profile .

However, the very precision that defines MR formulations also introduces their greatest challenge. Inappropriate control of drug release can lead to severe consequences, ranging from reduced therapeutic efficacy (if the drug is released too slowly or incompletely) to increased toxicity (if the drug is released too rapidly) . This is often referred to as the “Goldilocks” challenge of MR formulations: the release profile must be just right—not too fast, not too slow, but precisely controlled to remain within the narrow therapeutic window. Achieving this delicate balance requires a profound understanding of drug-polymer interactions, the physicochemical properties of the API, and the complex physiology of the gastrointestinal (GI) tract. It’s a scientific tightrope walk that demands meticulous design and rigorous testing.

Overcoming Dose Dumping and Food Effects

Beyond the inherent complexities of controlled release, MR generic formulations must contend with dynamic physiological variables, notably the risks of “dose dumping” and “food effects.”

Dose dumping is a critical safety concern for MR formulations. It occurs when a large, potentially toxic, amount of medication is released rapidly and prematurely from the dosage form, leading to dangerously high drug concentrations in the bloodstream . This can happen if the formulation’s integrity is compromised (e.g., by alcohol interaction, or mechanical stress) or due to specific physiological conditions. The consequences can range from severe adverse effects to outright toxicity. For example, some generic versions of extended-release Concerta, used to treat ADHD, were found not to dissolve at the same rate as the brand, leading to inconsistent doses and potentially dose dumping .

Food effects represent another significant challenge. The presence of food in the gastrointestinal tract can profoundly impact the absorption of MR formulations, potentially altering gastric emptying rates, GI transit times, and local pH conditions, all of which can disrupt the intended drug release profile . For instance, a high caloric meal can significantly delay gastric emptying, retaining a drug in the stomach for an extended period. If an MR formulation is designed to release its active ingredient in the small intestine, prolonged gastric retention due to food could lead to an unintended and premature release in the stomach, altering the PK profile and potentially causing adverse events . To mitigate these risks, food effect studies are strongly recommended early in the development of new MR formulations to inform appropriate intake recommendations (e.g., take with or without food) that can be included in the product labeling .

The variability inherent in human physiology, particularly the dynamic environment of the gastrointestinal tract (e.g., fed versus fasted states, individual differences in motility and pH), presents a significant and often unpredictable challenge for MR generic formulation. Designing a robust MR product means engineering it to perform consistently despite these inherent physiological fluctuations. This demands not only sophisticated formulation design but also extensive and often costly in vivo studies to characterize drug release under various conditions and ensure that the product is resilient to physiological variability . It is a complex endeavor that pushes the boundaries of pharmaceutical science to ensure consistent therapeutic outcomes for patients.

Parenteral Formulations: The Demands of Injectables

Parenteral drug products, administered directly into the body, offer rapid and precise drug delivery but impose exceptionally stringent formulation and manufacturing requirements on generic developers.

Sterility, Pyrogenicity, and Isotonicity: Non-Negotiable Standards

Parenteral drugs, which include intravenous, intramuscular, and subcutaneous injections, bypass the body’s natural defense mechanisms, delivering medication directly into the systemic circulation or tissues . This direct route of administration necessitates exceptionally stringent regulatory requirements, far exceeding those for oral medications .

Three non-negotiable standards define the landscape of parenteral formulation:

- Sterility: Parenteral formulations must be absolutely free of microorganisms and contaminants . Achieving this requires manufacturing under strictly sterile conditions, often within highly controlled clean rooms utilizing advanced aseptic manufacturing systems . This demands exhaustive investments in specialized equipment and facilities, as existing units used for other formulations often cannot be directly repurposed .

- Pyrogenicity: Beyond sterility, parenteral products must be pyrogen-free, meaning they are devoid of fever-inducing substances, primarily bacterial endotoxins . Ensuring this requires meticulous control throughout the manufacturing process, often employing advanced systems like microfluidic biosensors and affinity chromatography for real-time endotoxin detection and removal .

- Isotonicity: The final parenteral formulation must possess the same osmolarity (concentration of solutes) as human body fluids to prevent cell damage, pain, or irritation at the injection site . This delicate balance is typically adjusted using osmolality-modifying agents such as sodium chloride or dextrose .

The non-negotiable demands for absolute purity, pyrogen-free status, and physiological compatibility in parenteral formulations translate directly into significantly higher manufacturing costs and infrastructure requirements for generic developers compared to oral solids. This creates a substantial barrier to entry, explaining why there are often fewer generic competitors in the injectable segment . This is the cost of absolute purity—a necessary investment to ensure patient safety when the body’s natural defenses are bypassed.

Stability of Biologics and Complex Injectables

Beyond the fundamental requirements of sterility and pyrogenicity, maintaining the stability of parenteral formulations, particularly complex injectables and biologics, presents its own set of formidable challenges.

Parenteral drugs, especially biologics (large, complex protein-based molecules), are inherently prone to degradation . Their complex structures are highly sensitive to environmental factors such as temperature, pH, humidity, and light. Maintaining their stability requires meticulous control of these conditions not only throughout the manufacturing process but also during transport (often necessitating expensive cold-chain logistics) and storage .

The pharmaceutical industry has witnessed rapid growth in the area of complex injectable products, including novel formulations like nanoparticles, liposomes, microspheres, suspensions, and emulsions . These advanced delivery systems are increasingly developed for parenteral applications due to their ability to offer improved pharmacokinetic/pharmacodynamic (PK/PD) behavior, reduced dosing frequency, and minimal adverse effects . For example, long-acting injectables (LAIs) can provide sustained drug release for prolonged durations, overcoming limitations of conventional formulations such as low adherence and frequent dosing requirements .

For parenteral generics, particularly complex injectables, formulation choices extend beyond mere drug stability and bioavailability; they directly influence patient experience and, ultimately, adherence. This means successful formulation goes beyond achieving bioequivalence to encompass a holistic, patient-centric design. Consider the shift towards pre-filled syringes and auto-injectors. While their regulatory approval can be more complex, these specialized delivery systems offer significant benefits at the point of use, including fewer administration errors, reduced likelihood of contamination, and easier self-administration by patients or their caregivers . This demonstrates a crucial interplay of formulation, delivery, and patient adherence, where the formulation is designed not just for efficacy but also for optimal patient use, becoming a key differentiator in the market.

Topical and Ophthalmic Formulations: Local Action, Systemic Hurdles

Topical and ophthalmic formulations are designed for localized drug delivery, yet they face unique challenges in permeating biological barriers while minimizing systemic exposure.

Skin and Ocular Barriers: Enhancing Permeation and Retention

Topical formulations, applied to the skin, and ophthalmic formulations, applied to the eye, are intended to exert their therapeutic effects locally. However, achieving effective drug delivery to the target tissue is profoundly challenging due to the formidable natural barriers posed by the skin and the intricate physiology of the eye .

For ophthalmic drugs, low ocular bioavailability is a major limitation. The eye’s unique anatomy and physiology present multiple barriers:

- Limited Volume: The eye can only accommodate a small volume (around 30 µL) of eye drop, with most of the excess volume rapidly eliminated by reflex blinking .

- Tear Film Turnover: The rapid turnover of the tear film (0.5 to 2.2 µL/min) quickly clears drug molecules via nasolacrimal drainage .

- Permeation Barriers: Tight junctions between epithelial cells form a strong barrier for hydrophilic drugs, while drug efflux pumps and drug-degrading enzymes (e.g., cytochrome P450) in the epithelium further limit bioavailability .

To overcome these barriers and enhance drug permeation and retention, generic developers employ innovative formulation strategies:

- Viscosity Modifiers: Incorporating polymers such as hydroxypropyl methylcellulose (HPMC), hydroxyethyl cellulose (HEC), gellan gum, or xanthan gum can increase the viscosity of ophthalmic formulations. This prolongs contact time with the ocular tissue and reduces rapid drainage, thereby enhancing drug efficacy .

- Permeation Enhancers: The addition of surfactants, bile acids, or chelating agents can increase corneal penetration . Prodrug formulations, which are pharmacologically inactive but more lipophilic derivatives of the drug, can also enhance penetration by metabolizing to the active compound within the cornea after absorption .

- Nanotechnology: Nanosuspensions, for instance, can improve the bioavailability of poorly soluble (hydrophobic) drugs by increasing their solubility and extending their residence time on the ocular surface .

This leads to a fascinating paradox: for topical and ophthalmic generics, the challenge isn’t simply delivering the drug; it’s ensuring sufficient local bioavailability to achieve the therapeutic effect without significant systemic absorption. This delicate balance requires innovative formulation strategies that prioritize local efficacy while minimizing systemic side effects. Simple bioequivalence metrics, often sufficient for systemic drugs, are frequently inadequate for these localized delivery systems, necessitating sophisticated in vitro and in vivo studies, such as cutaneous pharmacokinetics, to precisely characterize drug action at the target site .

Formulation Viscosity and Particle Size: Impact on Efficacy

For topical and ophthalmic formulations, seemingly minor micro-level attributes, such as the particle size of the active pharmaceutical ingredient (API) and the viscosity of the excipient matrix, can have a profound impact on the drug product’s macro-level performance and therapeutic efficacy.

In topical formulations like creams or ointments, the particle size or morphology of the drug substance and the consistency (viscosity) of the white petrolatum or other excipient bases are considered critical quality attributes . Any deviation in these parameters can lead to a shift in content uniformity (ensuring even drug distribution), drug release, and the desired dermal distribution of the drug .

Similarly, in ophthalmic suspensions, the particle size of the API directly influences its residence time and activity on the precorneal surface . Smaller particles may replenish the drug absorbed by ocular tissue more quickly, while larger particles might be retained longer, slowing drug dissolution. However, excessively large particles can also cause practical problems, such as clogging the tip of the medication bottle during instillation, which directly affects dosage consistency and the delivered drug concentration . Studies have shown differences in particle sizes between generic and brand-name ophthalmic products, potentially impacting efficacy .

This highlights a crucial principle: for these localized dosage forms, the micro-level determinants of macro-level performance are paramount. Achieving therapeutic equivalence requires extremely precise control over material attributes and manufacturing processes. Generic developers must meticulously characterize not only the chemical composition but also the physical microstructure and rheological properties (e.g., flow behavior, viscosity) of the Reference Listed Drug (RLD) to ensure their generic product delivers the same consistent and effective dose to the target site.

Inhalation Formulations: The Device-Drug Interplay

Inhalation drug products (IDPs) offer a direct route to the lungs for treating respiratory conditions or achieving systemic effects. However, developing generic IDPs is exceptionally complex, primarily due to the inextricable link between the drug formulation and its delivery device.

Aerosol Properties and Particle Size Distribution: Delivering to the Lungs

Pulmonary drug delivery is inherently a “combination product”—it involves integrating a drug formulation with a specialized delivery device, such as pressurized metered-dose inhalers (pMDIs), dry powder inhalers (DPIs), or nebulizers . The primary objective of an inhalation product is to efficiently deliver the active pharmaceutical ingredient (API) to the patient’s nose, airways, or lungs .

Achieving this precise delivery requires meticulous control over the drug product’s aerosol properties and particle size distribution. The size and characteristics of the aerosolized particles directly determine where the drug will deposit within the respiratory tract (e.g., upper airways, large bronchi, or deep lung alveoli), which is critical for its therapeutic effect .

To gain regulatory approval, generic inhalation drug products must demonstrate pharmaceutical equivalence (same active ingredients, dosage form, strength, route of administration), bioequivalence (no significant difference in drug absorption and action), and therapeutic equivalence (same clinical effect and safety profile) as the Reference Listed Drug (RLD) . The FDA employs a comprehensive “weight-of-evidence” model for this assessment, which includes:

- In vitro studies: Comparing aerosol properties, particle size distribution, and delivered dose of the generic and RLD .

- Pharmacokinetic (PK) studies: Evaluating systemic exposure .

- Pharmacodynamic (PD) or clinical endpoint studies: Assessing the therapeutic effect, especially when PK studies alone are insufficient .

The delivery device is not merely a container for inhalation generics; it is an integral component of the formulation that critically influences drug performance. Variations in device design, manufacturing tolerances, or even the materials used can directly alter the aerosol properties and particle size distribution, leading to different drug delivery profiles and potential bioequivalence failures . This means generic developers cannot simply copy the drug; they must also replicate or design a device that ensures equivalent drug delivery performance, effectively making the device a “critical excipient” in its own right.

Device-Specific Challenges: pMDIs, DPIs, and Nebulizers

Developing inhalation products is notoriously costly and time-consuming, carrying a significant risk of major delays and increased development costs . This complexity stems from several factors unique to these drug-device combinations:

- Conflicting User Requirements: The device must balance diverse and often conflicting demands from users, payers, and healthcare professionals. For example, it needs to be safe against inadvertent actuation when carried in a pocket, yet easy to open and operate by a patient with impaired vision or dexterity .

- Product Complexity: The chemical and physical properties of the drug, along with its pharmacodynamic and pharmacokinetic characteristics, profoundly influence the selection of the most suitable formulation and device type. The drug’s potency dictates dose size, and the formulation must be chemically and physically stable within the device for an extended shelf-life, often requiring protection from moisture, light, and oxygen .

- Inextricable Performance: The performance of an inhalation product is an inseparable function of both the drug formulation and the device. Any change in one component can impact the other, making optimization a complex iterative process.

The complexity of inhalation devices, coupled with the lack of direct substitutability concepts in some regulatory regions (e.g., the EU, where approval depends on demonstrating drug delivery equivalence rather than direct interchangeability), means generic developers face a regulatory “black box” . They must not only prove bioequivalence but also demonstrate equivalent drug delivery performance through a battery of in vitro, PK, and potentially PD or clinical studies. This is often done without clear, harmonized global guidelines for device-specific parameters, making the regulatory pathway less predictable and significantly more resource-intensive. It’s a challenging landscape where scientific rigor meets regulatory ambiguity, demanding a high level of expertise and investment.

Biosimilars: The Pinnacle of Complex Generic Development

Biosimilars represent the most advanced and challenging frontier in generic drug development, pushing the boundaries of analytical science and regulatory oversight.

Demonstrating High Similarity: Beyond Bioequivalence

Biosimilars are generic versions of complex biologic drugs, which are typically large, intricate molecules derived from living organisms (e.g., proteins, monoclonal antibodies) . Unlike small-molecule generics, which must contain the “same chemical substance” as their reference product, biosimilars are fundamentally not identical to their reference biologics . This crucial distinction arises from the inherent variability of recombinant proteins and the subtle differences that inevitably occur during their complex production processes. Factors like the specific expression system used (e.g., Chinese Hamster Ovary (CHO) cells vs. Human Embryonic Kidney 293 (HEK293) cells), cell culture conditions (pH, oxygen, nutrients), and bioprocessing variables (purification methods, buffer composition) can all lead to structural nuances .

Therefore, biosimilars are not required to demonstrate strict bioequivalence in the same way as small-molecule generics. Instead, they must demonstrate “high similarity” to the reference biologic. This requires a comprehensive “totality of evidence” approach, which is a far more extensive and demanding process. This evidence package includes:

- Extensive Analytical and Physicochemical Characterization: High-resolution techniques are used to compare the primary protein sequence, three-dimensional structure, and other physical attributes .

- Biologic and Functional Characterization: Studies to compare biological activity, binding affinity, and mechanism of action .

- Non-clinical Studies: Including comparative toxicity assessments in animal models .

- Clinical Trials: Often required to confirm comparability in terms of safety, efficacy, and immunogenicity in human subjects, especially if any residual uncertainty remains after analytical and non-clinical studies .

Developing biosimilars is akin to replicating a complex biological fingerprint, not just a simple chemical formula. The profound challenge lies in ensuring that these slight variations in complex structures—such as post-translational modifications (PTMs) like glycosylation patterns—do not lead to clinically significant differences in efficacy, safety, or, critically, immunogenicity. Even minor differences in these complex biological attributes can trigger an unwanted immune response in patients, making the “fingerprint” challenge a high-stakes endeavor for biosimilar developers .

Post-Translational Modifications and Immunogenicity Concerns

The most formidable and often unpredictable challenge in biosimilar development is managing post-translational modifications (PTMs) and addressing potential immunogenicity.

Achieving consistent post-translational modification (PTM) profiles, such as glycosylation patterns (the attachment of sugar molecules to proteins), is a major hurdle for biosimilars. These modifications are highly sensitive to the specific cellular machinery and environmental conditions during protein production. Differences in expression systems, cell culture conditions (e.g., pH, oxygen, nutrient availability), and bioprocessing variables (e.g., purification methods, buffer composition) can all lead to variations in PTMs between the biosimilar and its reference product .

These subtle structural nuances necessitate strict regulatory oversight to ensure that the biosimilar is truly therapeutically equivalent to its reference counterpart in terms of efficacy, safety, and quality . However, the most significant concern arising from these variations is immunogenicity—the potential for the human body to develop an immune response against the biosimilar drug. This immune response can range from benign (e.g., development of anti-drug antibodies that do not affect efficacy) to severe (e.g., neutralization of the drug’s therapeutic effect, leading to loss of efficacy, or serious adverse events like anaphylaxis or autoimmune reactions) .

The unpredictable nature of the immune response poses a significant safety risk and is a primary driver of the extensive and costly clinical studies required for biosimilar approval . Even if analytical and functional studies show high similarity, a clinical trial is often required to rule out clinically meaningful differences in immunogenicity. This makes biosimilar development a high-risk, high-reward endeavor. The challenge is not just to produce a similar molecule, but to ensure that the body perceives it as therapeutically interchangeable, without triggering an unwanted immune reaction.

Pioneering Solutions and Innovative Strategies

The formidable challenges in generic drug formulation are met with equally powerful solutions, driven by a proactive approach to quality, advanced analytical capabilities, computational prowess, and novel drug delivery systems.

Quality by Design (QbD) and Process Analytical Technology (PAT): A Proactive Paradigm

Traditional pharmaceutical development often relied on empirical approaches and extensive end-product testing to ensure quality. However, the increasing complexity of drug products and the demand for efficiency have spurred the adoption of a more proactive paradigm: Quality by Design (QbD) and Process Analytical Technology (PAT).

Implementing QbD for Robust Formulation Development

Quality by Design (QbD) is a systematic approach to pharmaceutical development that fundamentally shifts the focus from “testing quality in” to “designing quality in” from the very beginning of the development process . It emphasizes a deep understanding of the product and the manufacturing process, all based on sound scientific principles and robust quality risk management .

The implementation of QbD involves several key elements:

- Quality Target Product Profile (QTPP): This is a prospective summary of the desired quality characteristics of the drug product, defined with patient safety and efficacy in mind . It sets the ultimate goal for the formulation.

- Critical Quality Attributes (CQAs): These are measurable properties of the drug product that are critical to ensuring its quality, safety, purity, and efficacy from the patient’s perspective. CQAs are directly derived from the QTPP .

- Critical Material Attributes (CMAs) and Critical Process Parameters (CPPs): CMAs are the physical, chemical, biological, or microbiological properties of input materials (e.g., APIs, excipients) that must be controlled to ensure the desired quality of the output material. CPPs are the process parameters (e.g., mixing speed, temperature, pressure) whose variability has an impact on a CQA and therefore should be monitored or controlled to ensure the process produces the desired quality .

- Risk Assessment and Design of Experiments (DoE): QbD employs tools like Quality Risk Management (e.g., Failure Mode and Effects Analysis – FMEA) to prospectively identify potential risks to product quality. This is followed by Design of Experiments (DoE), a statistical methodology used to systematically study the effects of multiple variables (CMAs and CPPs) on product and process performance, enabling optimization and robust development .

For generic drugs, QbD is particularly transformative. It moves development from an empirical, trial-and-error process, which can be labor-consuming, tedious, and costly , to a knowledge-driven, proactive one. By systematically understanding the relationships between formulation components, manufacturing process variables, and product quality, companies can identify the precise variables that need adjustment to achieve bioequivalence and consistently reduce product variability . This approach significantly reduces development timelines, minimizes costly failures (e.g., failed bioequivalence studies or batch rejections), and enhances product robustness, thereby mitigating regulatory risks and improving overall cost-efficiency . QbD is not just a scientific methodology; it is a strategic business tool for de-risking and accelerating development by shifting from a reactive “test-and-fix” mindset to a proactive “design-for-quality” paradigm.

PAT: Real-Time Monitoring for Enhanced Quality Control

Complementing Quality by Design (QbD) is Process Analytical Technology (PAT), a framework for designing, analyzing, and controlling pharmaceutical manufacturing processes through timely measurements of critical quality and performance attributes of raw and in-process materials and processes.

PAT involves the real-time monitoring and control of manufacturing processes, ensuring consistent product quality and significantly reducing product variability . It integrates seamlessly with QbD principles by providing the tools necessary for enhanced process understanding and control. PAT tools encompass a range of advanced analytical techniques that can provide real-time data on critical process variables. Examples include Raman spectroscopy, Near-Infrared (NIR) spectroscopy, and Fourier-Transform Infrared (FTIR) spectroscopy, which can monitor parameters like pH, osmolality, and API concentration directly within the manufacturing line .

By implementing PAT, generic manufacturers can achieve a new level of quality assurance. This technology allows for immediate detection of deviations, enabling prompt corrective actions, which in turn enhances product consistency, reduces batch failures, and minimizes production variability . These quality improvements not only mitigate regulatory risks but also serve as powerful competitive differentiators in markets where quality concerns have historically impacted confidence in certain generic products.

PAT represents a crucial step towards the digital transformation of generic drug manufacturing. It signifies a shift from discrete batch testing, where quality is assessed after production, to continuous, real-time quality assurance, where quality is built into and monitored throughout the process. This paradigm shift enables more agile and efficient manufacturing operations, which is vital in a highly competitive, cost-sensitive market. Moreover, it lays the groundwork for future advancements like continuous manufacturing, fundamentally changing how drugs are produced and how their quality is ensured.

Advanced Analytical Characterization: Deeper Insights into Drug Products

In the pursuit of bioequivalence and therapeutic equivalence, generic drug developers rely heavily on sophisticated analytical techniques to gain profound insights into both the Reference Listed Drug (RLD) and their own proposed generic product.

High-Resolution Techniques for Structural and Physicochemical Analysis

Analytical techniques are the backbone of drug development, holding a critical position in bioequivalence studies by enabling the precise measurement of a drug’s active pharmaceutical ingredient (API) presence and concentration within the human body . However, as innovator drug products become increasingly complex—especially biologics and nano-sized products with intricate supra-molecular structures like protein-drug complexes or iron colloids—the demands on analytical sophistication have escalated . Merely replicating a chemical formula is no longer sufficient; generic developers must employ cutting-edge high-resolution techniques to characterize subtle structural and physicochemical differences that could profoundly impact drug performance.

Comprehensive physicochemical characterization is required to gain deep insight into product quality that can eventually affect in vivo performance . This includes meticulous assessment of properties such as particle morphology, surface potential, size distribution, carrier composition, and the precise physical state of the encapsulated drug .

A suite of advanced analytical techniques is indispensable for this level of detail:

- X-ray Powder Diffraction (XRPD): Used to identify and quantify crystalline forms (polymorphs) and assess overall crystallinity .

- Thermal Analysis (Differential Scanning Calorimetry – DSC, Thermal Gravimetric Analysis – TGA, Hot-Stage Microscopy – HSM): Provides information on thermal transitions, phase changes, and stability, crucial for understanding polymorphic behavior and degradation .

- Spectroscopic Methods (Raman spectroscopy, Solid-state Carbon-13 Nuclear Magnetic Resonance – NMR-13C): Offer detailed insights into molecular structure, bonding, and arrangement within the solid state .

- Particle Size Analyzers: Essential for characterizing the size distribution of drug particles, which is critical for dissolution and absorption, especially for poorly soluble drugs .

This increasing complexity of RLDs is driving an “arms race” in analytical sophistication for generic developers. The challenge is not just to possess these advanced tools, but to have the expertise to use them to detect subtle, performance-critical differences that are not immediately obvious. This pushes the boundaries of analytical science and necessitates significant investment in analytical R&D capabilities.

Bioanalytical Methods for Bioequivalence Assessment

The ultimate proof of a generic drug’s therapeutic equivalence often lies in its bioequivalence (BE) profile in human subjects. This requires robust bioanalytical methods to accurately quantify drug concentrations in biological samples over time.

Bioequivalence studies typically involve in vivo studies in human subjects where the pharmacokinetic (PK) profiles of the generic (test) drug and the reference drug are characterized and compared . The key PK parameters assessed are the peak drug plasma concentration (Cmax), which is a measure of the rate of absorption, and the area under the drug plasma concentration versus time profile (AUC), which reflects the extent of absorption .

To accurately measure the presence and concentration of the active pharmaceutical ingredient (API) and its metabolites in biological samples (e.g., blood plasma), a range of highly sensitive and specific bioanalytical techniques are employed:

- Liquid Chromatography-Mass Spectrometry (LC-MS): Widely regarded for its precision, high sensitivity, and specificity, LC-MS is adept at separating and quantifying drugs and their metabolites in complex biological matrices .

- Gas Chromatography-Mass Spectrometry (GC-MS): A valuable tool, particularly for drugs that are volatile or can be derivatized to a gaseous state, making it suitable for compounds with high volatility and low molecular weight .

- High-Performance Liquid Chromatography (HPLC): A versatile and foundational analytical method, HPLC is a workhorse for precisely separating and quantifying APIs. Reverse-phase HPLC is well-suited for hydrophobic drugs, while normal-phase HPLC is preferred for polar compounds .

- Immunoassays (e.g., Enzyme-Linked Immunosorbent Assay – ELISA): Crucial for analyzing larger molecules such as proteins and peptides, these methods rely on the specific binding of antibodies to drug molecules, making them ideal for high-throughput quantification of biologics and biosimilars .

- Capillary Electrophoresis and UV-Visible Spectrophotometry: Other methods employed, recognized for high resolution, swift analysis times (Capillary Electrophoresis), and measuring light absorption properties (UV-Vis) .

The sheer volume and complexity of bioanalytical data generated from these rigorous BE studies necessitate advanced data analytics and statistical modeling. This shift moves beyond simple pass/fail criteria to a more nuanced, predictive understanding of drug performance. It paves the way for virtual bioequivalence (VBE) simulations and reduces the need for extensive human testing, optimizing resource allocation and accelerating development timelines. This highlights the growing importance of computational and statistical expertise in generic drug development, transforming raw data into actionable intelligence.

Computational Modeling and In Silico Prediction: Accelerating Development

The pharmaceutical industry is increasingly turning to computational modeling and in silico (computer-based) prediction tools to streamline drug development, reduce costs, and accelerate market entry for generic drugs. These technologies offer a powerful alternative to traditional, often time-consuming and expensive, experimental approaches.

Physiologically Based Pharmacokinetic (PBPK) Modeling: Virtual Bioequivalence

Physiologically Based Pharmacokinetic (PBPK) modeling represents a sophisticated scientific approach that establishes predictive relationships between laboratory-based drug release profiles (in vitro) and pharmacokinetic behavior in humans (in vivo) . These mathematical models function as knowledge management systems, integrating scientific understanding and existing data across various aspects of drug products, including formulation, in vitro and in vivo release, pharmacokinetics (PK), pharmacodynamics (PD), and even clinical responses .

At its core, PBPK modeling simulates how a chemical is absorbed, distributed, metabolized, and excreted (ADME) over time within the human body. It achieves this by incorporating detailed physiological and biochemical characteristics, such as organ size, blood flow rates, and metabolic enzyme activities, alongside drug-specific properties like solubility, permeability, and protein binding .

The applications of PBPK modeling in generic drug development are transformative:

- Bioequivalence (BE) Assessment: PBPK modeling can support relative bioavailability (BA) and BE assessments, particularly valuable in challenging populations like pediatrics where extensive clinical studies are often not feasible or ethical . It can provide confidence in extrapolating adult BE results to pediatric populations, for example .

- Predicting Impact of Changes: It can effectively predict the in vivo effects of minor formulation changes, manufacturing process alterations, or even changes in manufacturing facilities . This predictive capability can significantly reduce the need for additional, costly in vivo studies, potentially supporting biowaivers .

- Regulatory Acceptance: The FDA has demonstrated a willingness to approve generic drugs using PBPK modeling to support alternative BE approaches. A notable success story is the approval of generic diclofenac sodium topical gel, 1%, where PBPK modeling and simulation supported an alternative BE approach in lieu of a comparative clinical endpoint BE study, leading to first-cycle approval .

PBPK modeling serves as a crucial bridge, connecting in vitro data to in vivo outcomes and enabling a “virtual” testing environment. This capability fundamentally reshapes the generic drug development paradigm, moving it towards a more efficient, science-driven, and ethical approach by significantly reducing the reliance on traditional, expensive, and time-consuming human clinical trials . It is a cornerstone of “model-informed drug development” (MIDD), aiming to decrease development uncertainty, cost, time, attrition, and failure rates .

In Silico Tools for Formulation Optimization and ADME Prediction

Beyond PBPK modeling, a broader suite of in silico (computer simulation) tools is revolutionizing generic drug development, offering unprecedented capabilities for formulation optimization and drug property prediction.

In silico modeling and simulation solutions are proving immensely valuable for Abbreviated New Drug Application (ANDA) programs. These computational methods can effectively predict the behavior of a drug within the human body, identify potential safety concerns early in development, and optimize dosing regimens, thereby streamlining the overall drug development process and reducing the need for costly and time-consuming clinical trials .

Specific applications of these advanced computational tools include:

- Formulation Optimization: By simulating how different formulation components interact and influence drug behavior in the body, these models can guide the development of effective and safe drug products, reducing the number of physical experiments required .

- ADME Predictions: In silico tools can accurately predict a compound’s absorption, distribution, metabolism, and elimination (ADME) properties. This provides crucial insights into potential safety issues, helps optimize pharmacokinetic profiles, and significantly reduces the time and cost associated with traditional ADME studies .

- Dissolution Safe Space: Computational models can assess the rate and extent to which a drug dissolves in a specific medium in silico, helping to define a “safe space” for dissolution parameters that ensures consistent performance .

- Inter-species PBPK Modeling: These models can predict how a drug or chemical will be distributed, metabolized, and eliminated across different species, including humans, thereby reducing the need for extensive animal testing and accelerating early-stage development .

The integration of Artificial Intelligence (AI) and Machine Learning (ML) with in silico modeling is poised to further revolutionize generic drug formulation. These cutting-edge technologies can analyze vast and complex datasets, uncover subtle patterns that might escape human detection, and dramatically improve prediction accuracy . This accelerates formulation optimization by rapidly screening potential candidates and reducing experimental iterations, offering a significant competitive edge in a fast-paced market. It represents a shift from merely predictive modeling to prescriptive design, where AI/ML can suggest optimal formulations based on desired performance characteristics.

Novel Drug Delivery Systems: Expanding Therapeutic Horizons

As the pharmaceutical landscape evolves, generic developers are increasingly leveraging novel drug delivery systems to overcome formulation challenges, enhance therapeutic profiles, and differentiate their products beyond mere price competition.

Nanotechnology: Enhancing Solubility, Bioavailability, and Targeting

Nanotechnology, involving the engineering of materials at the nanoscale (typically between 1 and 100 nanometers), has emerged as a groundbreaking solution for improving drug delivery, efficacy, and safety . This revolutionary technology is rapidly transforming how pharmaceutical products are developed and delivered, offering new possibilities for managing chronic conditions and addressing unmet medical needs.

The benefits of nanotechnology for generic drug development are multifaceted and significant:

- Enhanced Solubility and Bioavailability: Many active pharmaceutical ingredients (APIs) suffer from poor water solubility, which severely limits their absorption in the body. Nanoparticles can encapsulate these poorly soluble APIs, protecting them from degradation and significantly enhancing their solubility and bioavailability . Lipid-based nanocarriers, such as micelles and liposomes, are particularly effective at overcoming the acidic environment of the gastrointestinal tract, thereby enabling the oral administration of drugs that were previously limited to injectable routes .