Last updated: July 30, 2025

Introduction

Polyvinyl Alcohol (PVA) is a synthetic polymer with versatile applications spanning industries such as textiles, paper, packaging, adhesives, medical devices, and cosmetics. Its unique properties—biocompatibility, water solubility, film-forming ability, and chemical resistance—make it a critical component in multiple product lines. The increasing demand driven by technological advancements and regulatory shifts in healthcare, packaging, and consumer goods is fueling market growth. This analysis provides a comprehensive overview of the PVA market, including industry trends, supply-demand dynamics, competitive landscape, and price forecasts.

Market Overview

Global Market Size and Growth

The global PVA market was valued at approximately USD 800 million in 2022, with projections indicating a compound annual growth rate (CAGR) of around 6% from 2023 to 2030. The growth trajectory aligns with expanding industrial applications, especially in biodegradable packaging solutions and medical fields, driven by stricter environmental policies and innovations in drug delivery systems.

Key Application Segments

- Packaging and Films: The largest segment due to PVA’s film-forming and adhesive properties. Increasing demand stems from eco-friendly packaging mandates.

- Paper Industry: PVA’s water-soluble nature benefits paper coatings and adhesives.

- Medical and Pharmaceuticals: Growing use in drug delivery, wound dressings, and contact lenses owing to biocompatibility and safety.

- Textiles and Cords: Used as sizing agents and in textile finishing.

- Other: Cosmetics, coatings, and printing inks.

Regional Insights

- Asia-Pacific: Dominates the market, accounting for over 50% of global consumption, driven by large-scale manufacturing sectors in China, India, and Southeast Asia.

- North America: Second-largest contributor due to technological innovation and environmental regulations favoring eco-friendly polymers.

- Europe: Focused on sustainable packaging and medical applications, with key players emphasizing bio-based PVA variants.

Supply Chain and Market Drivers

Raw Material and Production

Polyvinyl alcohol is produced via hydrolysis of polyvinyl acetate, derived from ethylene or acetylene. The availability of these raw materials influences supply stability and costs. The shift toward bio-based manufacturing methods is an emerging trend to address sustainability concerns.

Market Drivers

- Environmental Regulations: Push for biodegradable, water-soluble polymers in packaging.

- Medical Advances: Rising demand for biocompatible materials in drug delivery systems.

- Technological Innovations: Enhanced film properties and process efficiencies expand application scopes.

- Consumer Preferences: Growing preference for eco-friendly products spurs demand for PVA-based packaging and textiles.

Market Challenges

- Price Volatility: Fluctuations in raw material costs, particularly due to crude oil dependency.

- Environmental Concerns: Resistance from certain jurisdictions over non-biodegradable aspects of synthetic polymers.

- Competition from Alternatives: Availability of natural polymers like starch and cellulose derivatives.

Competitive Landscape

Leading producers of PVA include Kuraray Co., Ltd., Sekisui Chemical Co., Ltd., and Shin-Etsu Chemical Co., Ltd., among others. These companies focus on technological R&D, expanding product portfolios (including bio-based PVA), and strategic partnerships to capture market share.

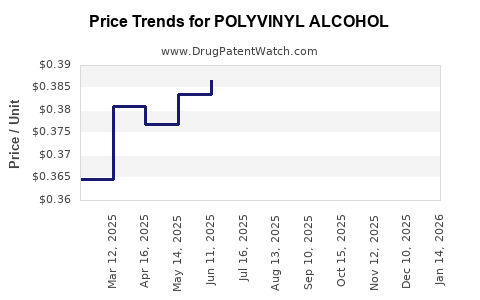

Price Dynamics and Trend Projections

Current Pricing Landscape

As of 2022-2023, PVA prices fluctuate between USD 3.50 and USD 5.00 per kilogram, influenced by raw material costs, regional demand, and production capacity constraints. Prices tend to be higher in North America and Europe due to logistic costs and stricter environmental standards.

Price Forecast (2023-2030)

Forecasts project a steady price increase at a CAGR of approximately 3-5%, driven by rising raw material costs, increasing end-user demand, and inflationary pressures. External factors such as geopolitical tensions and energy prices will also influence pricing, with expected stabilization post-2025 as new manufacturing capacities come online.

- 2023: USD 4.00 – USD 5.00/kg

- 2025: USD 4.50 – USD 6.00/kg

- 2027: USD 5.50 – USD 7.00/kg

- 2030: USD 6.50 – USD 8.50/kg

Price Influencing Factors

- Raw Material Cost Fluctuations: Ethylene and acetylene prices impact PVA production costs.

- Supply Chain Disruptions: Pandemics, geopolitical tensions, and transportation issues could lead to temporary variances.

- Regulatory Policies: Stricter environmental laws may increase costs related to sustainable manufacturing compliance.

Regulatory and Sustainability Trends

Governments worldwide are enforcing strict regulations on traditional plastics and promoting biodegradable alternatives. Initiatives such as the European Green Deal and China's microplastic bans accelerate demand for eco-friendly polymers like PVA, especially bio-based variants. Technological shifts toward bio-renewable raw materials are thus pivotal to future pricing and supply stability.

Opportunities and Strategic Considerations

- Bio-based PVA Development: Investing in research for bio-derived PVA can insulate suppliers from fossil fuel volatility.

- Geographic Expansion: Emerging markets in Africa and South America present growth opportunities for both sales and raw material sourcing.

- Product Diversification: Customizing PVA formulations for specific applications, like medical-grade or high-strength films, can command premium pricing.

- Sustainability Certifications: Certifications for biodegradable and environmentally friendly products can enhance market acceptance and pricing power.

Key Risks and Mitigation Strategies

- Raw Material Price Volatility: Hedging strategies and diversified sourcing can mitigate risk.

- Regulatory Uncertainty: Engaging in proactive compliance and sustainability initiatives minimizes legal risks.

- Market Competition: Continuous innovation and strategic partnerships are critical to maintaining competitive advantage.

Conclusion

The PVA market exhibits resilient growth prospects, buoyed by sustainable product advancements and expanding application horizons. Price projections indicate a gradual ascent, with factors such as raw material costs, regulatory frameworks, and technological innovations serving as principal drivers. Stakeholders should focus on R&D, sustainability, and strategic supply chain management to capitalize on market opportunities and mitigate associated risks.

Key Takeaways

- The global PVA market is projected to grow at a CAGR of approximately 6%, driven by eco-friendly packaging, medical, and industrial applications.

- Prices are expected to increase modestly over the next decade, influenced primarily by raw material costs and regional demand variations.

- Bio-based PVA development presents significant opportunities for market differentiation and premium pricing.

- Regulatory trends favoring biodegradable polymers will continue to bolster PVA demand, especially in Europe and North America.

- Supply chain diversification and sustainability initiatives are strategic imperatives for market participants to ensure price stability and competitive positioning.

FAQs

1. What are the main factors influencing the price of polyvinyl alcohol?

Raw material costs (ethylene, acetylene), supply-demand dynamics, energy prices, regulatory compliance costs, and regional logistics significantly influence PVA pricing.

2. How does the regional demand for PVA vary globally?

Asia-Pacific dominates due to manufacturing scale, while North America and Europe focus more on technologically advanced and sustainable applications, affecting regional prices and growth rates.

3. Are bio-based PVAs commercially viable?

Yes. Advances in bio-renewable raw materials and manufacturing processes are making bio-based PVAs more competitive, with growing adoption in environmentally-conscious markets.

4. What are key applications driving future PVA demand?

Medical devices, biodegradable packaging, adhesives, and textiles are primary growth drivers, with new applications emerging in drug delivery and eco-friendly consumer products.

5. What strategies can companies adopt to navigate market volatility?

Diversifying raw material sources, investing in R&D for sustainable variants, enhancing supply chain resilience, and compliance with evolving regulations are essential strategies.

References

- Market Research Future. (2022). Polyvinyl Alcohol Market Analysis.

- Mordor Intelligence. (2022). Polyvinyl Alcohol (PVA) Market - Forecast & Analysis.

- KARAY Co., Ltd. Annual Reports. (2022). Strategic Outlook.

- Environmental Policy Reports. European Commission. (2021). EU Green Deal — Sustainable Packaging Initiatives.

- Industry Publications and Technical Journals on Polymer Markets. (2022).